Manufacturers in the food processing industry have an increasing need for integrated packaging machines. Square metres are scarce and expensive. BluePrint Automation (BPA), supplier of packaging lines, is responding to their need with a total packaging solution with a higher output and small footprint.

According to Jos van Oekel, sales director at BPA, innovations in the packaging industry are driven by this development. “A German confectionery producer has been using BPA machines such as delta robots, case erectors and closer and lid applicators for many years. They have asked us to develop a total packaging solution in which these separate modules and functions are integrated in one mono block machine to increase the output per square metre.”

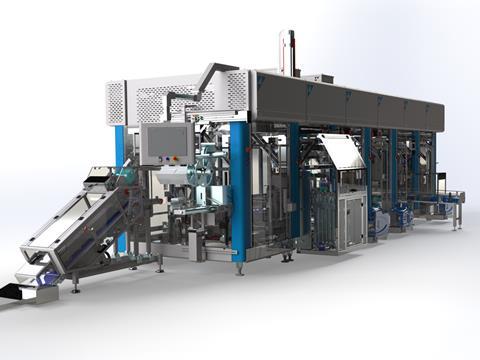

Small footprint

The result is total packaging concept “Quest” with a footprint of only 20-25 square metre. Within this reduced floor space multiple types of cases are erected, filled, labeled and closed with tape or hot melt or lidded. Both the bags and the cases are checked on correct weight and rejected if necessary. According to Van Oekel multinationals in the food processing industry are very interested in integrated machines such as the Quest. Van Oekel: “We often see that factories are not set up for automating manual processes. There simply is not enough space.”

Challenge

BPA considers it a challenge to find solutions for limited spaces. Van Oekel: “Take the bag making and filling machines used by snack manufacturers. Those machines are often placed so close together that no packaging machine can fit in between. We then offer a solution that combines two or more form-fill-close machines with one case packer, thus creating space for a fast and efficient packaging line.” Van Oekel expects this trend to continue during the upcoming years. “Especially in new factories efficient use of square meters is leading. Our Quest machine complies with the needs of the food processing industry now and in the future.”

More info: