As a designer and manufacturer of pharmaceutical packaging and delivery systems, West Pharmaceutical Services, Inc. has fully embraced 3D print technology. Elisabeth Skoda speaks to Chris Evans, innovation VP and Brian Costello, manager for design and user experience at the company, to find out more about advances in the sector.

How important is 3D printing at West Pharmaceutical Services?

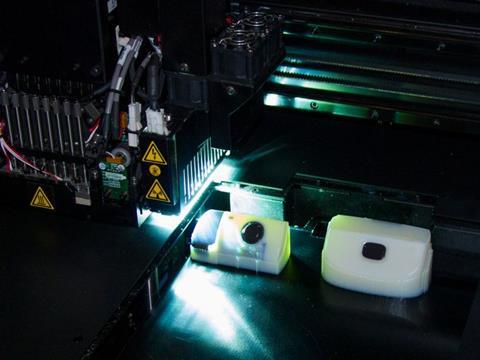

Chris Evans: Ten years ago, West Pharmaceutical Services bought its first 3D printers, and this was the start of what is now our focus in 3D printing at our centre of excellence at our Innovation Center in Washington NJ. West has always had a maker culture, trying things out.

Brian Costello: Here at the 3D printing centre of excellence within West we keep our finger on the pulse of technologies, constantly leverage applications and make sure that we’re looking out for what’s new in metals, plastics materials and rubbers.

What technological advances have you observed in the last ten years?

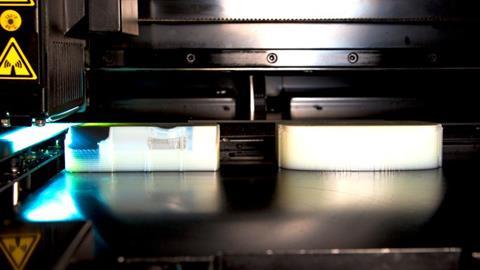

Chris Evans: Technologies have become incredibly flexible and inexpensive. We have seen major advancements in materials applications, and it is important to progress and leverage them. It is now possible to not only make early prototypes, user studies, or early evaluations of technology but also help create initial primary packaging solutions. One example are syringes and cartridges. We have the means to also make parts that are clear, to simulate a final cartridge or product, which ultimately is driving final device size. We are able to use printed components to leverage other technologies such as vacuum forming, and forming of a final package. So we are not just utilising tools to create a product but evaluate the whole user experience from start to finish. We have also seen resolution and fidelity levels in machines increase drastically over the years. We achieve much finer quality, and it is getting hard to tell the prototype apart from the final part.

Brian Costelllo: We have seen technologies evolve over the years. For example, a 3D printer ten years ago printed one material. Technology has advanced, now different plastics can be printed in different elasticities, mixing material and different variations of rubber. We never dreamed what the advancement in materials would make possible and that we could 3D print mould components. Traditional manufacturing of moulds takes weeks, if not months, but now we can 3D print them in hours and we can have plastic parts in days, drastically reduced our development time frame.

How have the capabilities of 3D printing evolved in recent time?

Key advancements have been material based. We are now able to print fixtures to hold parts or to measure them. Fixtures were traditionally manufactured from aluminium, but now we are able to make them ourselves. All aspects of development process have been affected by 3D capabilities. 3D printers have become part of the production process, they allow us to make pieces and accessories that make processes and development quicker.

What are typical applications for the pharmaceutical packaging industry?

Chris Evans: 3D print is used in many different ways, spanning the whole range of early concept development through to commercialisation within in many industries. It can be used to spur and evaluate early ideas and learn from them.

Brian Costello: It offers the opportunity to save customers time and money, for example on the contract manufacturing side. Previously, customers would have to wait until there was pre-production moulded parts before they could start building a production line. Now we just 3D print them. Some of the larger machines are so efficient that you can print hundreds of units at the time. They are essentially pre-production samples. It allows users to run through the packaging line or capping line to get an idea of how efficient an automation line is going to be, what the efficiency is and how much it is going to cost. Customers don’t have to wait for moulded parts. It allows the process to happen faster and us to save money. Having 3D print technology in house allows us to have processes that would have taken months finished in days or even hours.

Are there any recent examples of innovation in the sector?

Chris Evans: We are keen to improve user experience. One important topic in our industry is focusing around self-injection and self-therapy. The wearable business is getting larger and larger. With our SmartDose platform, we are a leader in the market. It offers a wearable, subcutaneous injector with an integrated drug delivery system that incorporates human factors and usability testing to deliver a truly patient-centric approach to self-administration. We make copies of that product as early as possible, to enable user tests, honing in on the best and most efficient workflow for the user and be able to put parts in patients’ hands as early as possible.

What future developments do you foresee?

Chris Evans: It all comes back to material development. There is continuous work to develop more realistic materials, and lots of work going on at universities. They have developed homemade machines that use cells and even printed ear for burn victim. It is possible to print prosthetics or metal and titanium alloys for joint implants. Material advancement is going to broaden the field, more products can be made, more materials are going to be approved by the FDA to be on/in the body. We see 3D printers become production machines for medical devices or parts that go into them.

Brian Costello: I would like to reinforce one key point – the use of 3D printers as experimental tools. We embrace the technology, and different people in different areas/industries also embrace the technology. 3D printing builds a makers culture, and innovation processes cannot move forward without it.

More info: