In this edition of the Spotlight, we hear from Valco Melton about its involvement in the packaging line for K+P Handels, which is equipped with its gluing solutions.

When K+P Handels, a company dedicated to the sale and distribution of tobacco-related products, exceeded 20,000 shipments per month, its executives had to consider the automation of some processes, including packaging. This is when they decided to implement a Panotec packaging line that could pack up to twice the number of products with less workforce effort.

Dedicated to the sale and distribution of tobacco-related products in the south of Germany, this growing company owns multiple kiosks in Karlsruhe and conducts online sales through its website and platforms like eBay, Amazon, and Kaufland. Founded in a garage by three colleagues in 2013, the company has experienced a meteorical expansion and now occupies 2000 square metres of space, boasting a team of 90 employees.

A year ago, the packaging process was done manually using adhesive tape and required the labor of 35 operators. However, as the number of daily orders grew, the need to increase packing speed arose. This was crucial to meet shipping deadlines and maintain customer satisfaction while considering environmental implications. “We analyzed the need for increased space and additional workforce in the packaging process, considered the environmental implications, and reached the decision to implement automation,” asserts managing director Helmut Pribyl.

The switch to an automated packaging system came with the acquisition of a Panotec Opera on-demand packaging line, which is compact, fully automated, and perfectly suited K+P Handels’ needs.

The Panotec Opera line scans each item or set of items to be packed and produces a custom box adapted to each product’s dimensions. This system can pack from 3000 to 4000 boxes per day. In addition to being ideal for e-commerce, this innovative packaging line significantly contributes to a more sustainable production. The system only uses the necessary amount of cardboard for each box creation and utilizes trimmings as protective fillings, reducing cardboard waste. This eliminates the need to purchase different size boxes and box filler material, thus reducing the required storage space.

The Panotec Opera line at K+P Handels is equipped with Valco Melton’s gluing solutions. Valco Melton is a leading designer and manufacturer of adhesive dispensing systems and quality inspection solutions for a variety of industries. Sustainability and providing a more efficient use of resources are two of Valco Melton’s main drivers in the development of gluing equipment for the packaging industry.

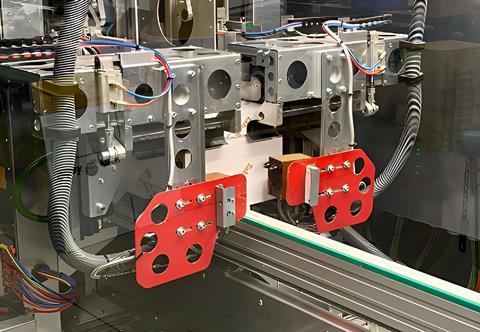

The forming and sealing of each box occurs in two phases. First, for the box formation and wrap-around process, small glue lines are applied with 4 MKF hot melt guns, known for their compact size and precision. Then, 2 EcoStitch electric guns apply hot melt dots to seal the flaps. After applying the shipping label, the box is finally ready for dispatch.

In addition to significant cardboard savings and reduced waste, incorporating EcoStitch all-electric applicators into the Panotec Opera packaging line allows K+P Handels to substantially reduce adhesive usage. The application of small adhesive dots instead of long beads allows savings of up to 60% in glue usage while maintaining an outstanding bonding quality. Moreover, this stitch application ensures a cleaner box opening and fibre tear without damaging the carton, leaving it in good condition for potential returns to the supplier. This reinforces the company’s commitment to a more sustainable manufacturing and sales process.

A fast-paced business like e-commerce requires advanced application technology, capable of working at the highest speeds. K+P Handels receives 40,000 online orders per month, normally with stringent delivery deadlines. The company is proud to serve them not only quickly but also in a resource-efficient manner. EcoStitch technology has played a part in this conversion. All-electric technology guarantees the highest working speeds. The lack of moving parts extends its lifespan beyond alternatives in the market and reports minimal faults or maintenance needs. This ensures an optimal packaging process without machine downtime stops that could delay order deliveries.

Gluing is a key part of the packaging process. Manufacturers require excellent control of the adhesive melting and guaranteed application precision with long-lifetime performance. Panotec Opera can work with Valco Melton’s range of melt units, such as the EC Series, a market classic standard, or the New Kube, a melter system with improved insulation that optimizes the heating process and allows better energy efficiency. Valco Melton’s systems can be configured directly from a touchscreen integrated into the main machine, eliminating the need to access melters or the use of external controllers.

As daily orders, and therefore daily packaging needs, became more demanding, K+P Handels needed the assurance of a technical service team that is always ready to assist its customers and end users. Valco Melton offers global support with local service through an extensive network of more than 30 direct technicians across Europe.

The synergies between Panotec Opera and Valco Melton systems have allowed K+P Handels to achieve a highly efficient packaging process that can further sustain the company’s growth in a demanding market like e-commerce - all while keeping sustainability and customer values at the core of the business.

About Valco Melton:

Established in 1952, Valco Melton is one of the world’s leading suppliers of adhesive dispensing systems and quality assurance equipment across various industries, including packaging, paper converting, and graphic arts. Headquartered in Cincinnati, Ohio, with research and manufacturing facilities throughout the USA, Canada, Europe, and India, and a dedicated network of direct sales and distributors worldwide, Valco Melton offers world-class dispensing system solutions to customers in over 96 countries across the globe.

This content was sponsored by Valco Melton.