In the second of our Wider View articles for 2025 with adhesives and coatings experts H.B. Fuller, we focus on how e-commerce retailers can ensure they meet their PPWR requirements while also addressing increased demand for fiber-based solutions to replace plastic where possible.

The packaging industry has now had some time to absorb the terms of the Packaging and Packaging Waste Regulation (PPWR), which went into effect on 11 February 2025.

The PPWR introduces harmonization of previously varied and largely non-mandatory packaging rules and regulations across Europe. This change has created a significant workload for Fast-Moving Consumer Goods (FMCGs) companies in the short term. Everything from recyclability standards to mandatory recycled content, reuse targets, reduction and more must be addressed.

This is particularly true for e-commerce. The challenges in this sector – with its multiple touchpoints to consider as well as the demands of protection, sustainability and performance – are somewhat different to those of traditional retail.

“While traditional retail relies on bulk-shipped, shelf-optimized designs, e-commerce requires robust, compact, and often fit-to-size solutions.”

“While traditional retail relies on bulk-shipped, shelf-optimized designs, e-commerce requires robust, compact, and often fit-to-size solutions,” explains Diana Neto, E-commerce Business Development Manager at H.B. Fuller. “For packaging converters, this means adopting materials that combine functionality with recyclability.”

Industry partners such as H.B. Fuller can help packaging converters address this through choosing the right adhesives and developing an environmentally robust overall packaging solution.

How can the right coating support paperization?

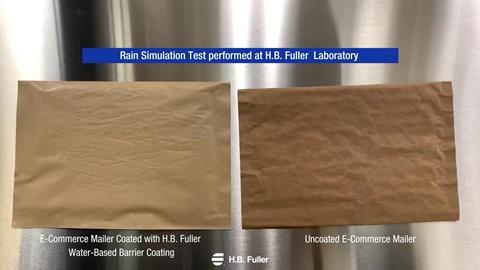

When you factor in the growing demand for fiber-based e-commerce solutions to replace plastics – at least where appropriate and possible – it adds yet another element of complexity. They must meet requirements for durability, moisture resistance and handling throughout the logistics journey, while still being recyclable and as light weight as possible. And for paper e-commerce packs to be viable, says Diana, they must also be feasible on existing lines – which is where water-based barrier coatings can come in.

“Historically, we’ve seen paper with PE coatings for e-commerce applications, but these structures often fall short of recyclability standards,” Diana says. “Water-based barrier coatings offer an alternative that performs on par with plastic films in terms of heat sealing and barrier protection, while still maintaining repulpability and are fully compatible with the paper recycling process. These coatings enable mono-material packaging that meets both functional and regulatory demands, without compromising sustainability demands or performance.”

And while there are still cases where paper is not feasible, Diana points out that technologies – and the possibilities these bring for paper when it comes to e-commerce – are improving all the time.

“Even in highly demanding applications like packaging for fresh or frozen meat and fish, which traditionally use EPS boxes or PE liners due to moisture sensitivity, paper-based solutions are proving successful,” Diana says. “In these cases, water-based barrier coatings are essential: they provide the necessary moisture protection and release properties while reducing plastic use.”

Furthermore, Diana says, “As paper is protected with this moisture-resistant layer, it will allow for packaging to withstand extreme temperature and humidity conditions across the entire supply chain, while providing a strong bond when heat sealed or closed with one of our compatible hot melt and water-based adhesives.”

Meeting PPWR requirements

Next, we examine specific targets in the PPWR that directly affect e-commerce. These targets present challenges for FMCGs aiming to increase their use of paper, particularly meeting performance requirements. We also explore how these challenges can be addressed – such as the selection of appropriate barrier coating technologies.

-

Material reduction: Under the PPWR, unnecessary transport and e-commerce packaging should be reduced through setting a maximum empty space of 50%.

“Barrier coatings provide paper-based packaging with some features that are intrinsic to plastic,” explains Diana. “They provide moisture resistance, and therefore, there’s no need to use an extra plastic bag inside to protect goods. Furthermore, barrier coatings allow for automated packaging machines to build on-demand and fit-to-size heat sealed mailers, that are lighter than corrugated but functional and as protective as plastic.”

-

Increased recyclability: A fundamental aim of the PPWR is to ensure that all packaging, whether it is reusable and includes recycled content, is recyclable (with a recyclability grade of C (70% or higher) from 2030. How can brands balance the need to design for recyclability with the need for product protection across long e-commerce supply chains and multiple touchpoints? Again, this is where water-based coatings can be a solution, says Diana.

“As we know, the majority of poly bags are still difficult to recycle in existing streams. In the face of this, retailers who had previously relied on plastic packaging now face the problem of not only maintaining packaging functionality but also ensuring its recyclability. Our testing has shown that water-based barrier coatings achieve improved fiber yield compared to PE coatings during the repulping process. This results in the potential for a higher volume of high-quality fibers to be added to the recycling stream.”

-

Increased reuse requirements: The PPWR mandates different reuse requirements for various end-use sectors but, it states that 10% of e-commerce transport packaging must be reusable by 2030, increasing to 50% by 2040.

Cardboard boxes are commonly reused, and paper mailers can also be reused within closed-loop systems. As Diana explains, this includes reuse in intralogistics—for picking multiple items or shipments from different fulfilment centres—and in B2C applications, where they can be used multiple times.

Scaling reuse systems is a well-recognized challenge that requires ongoing collaboration across the value chain. To illustrate this, Diana cites Amazon’s Sustainability Accelerator program as an example, where this type of packaging has been introduced in partnership with start-ups developing reusable packaging systems. Again, she says, “This is where barrier coatings can play a critical role enhancing strength, water resistance, and overall integrity to ensure packaging survives the many touchpoints and rough handling.”

-

Extended producer responsibility (EPR): Articles 44-47 of the PPWR introduce extended producer responsibility (EPR) for packaging producers, in the form of financial participation in the costs of collecting, sorting, and recycling packaging waste.

“This shift demands packaging designed for end-of-life processing, with a focus on mono-materials and minimal environmental impact,” Diana says. “Functional barrier coatings allow for replacing or reducing the plastic on packaging, improving recyclability and, thus, reducing the EPR costs, and aligning with evolving regulations.”

“Converters who adopt water-based coatings that meet both performance and recyclability standards are well-positioned to respond to this pressure while helping customers minimize eco-modulation penalties under EPR.”

Early collaboration is essential

Making the kinds of wholesale changes required to meet these new standards undoubtedly puts pressure on brands, particularly within the complexities of the e-commerce space. But it can be helpful if they view it not as an administrative burden but rather an opportunity to invest in a more circular future – in turn strengthening their market position, brand reputation, and sustainability credentials.

On that note, Diana distills the key pieces of advice H.B. Fuller would offer to its FMCG e-commerce partners looking to increase their use of fiber-based packaging within this new regulatory context:

- “Design for Real-World E-Commerce Conditions: Prioritize functionality such as moisture resistance, seal integrity, and durability, while ensuring recyclability.

- Ensure Recyclability from the Start: Choose coatings and adhesives that are certified or tested for compatibility with paper and board recycling streams.

- Leverage Testing and Certification: Use tools like ISTA testing (for transport durability) and CEPI testing (for recyclability validation). H.B. Fuller’s in-house testing aligns with CEPI’s standards and 4EverGreenAlliance protocol for paper repulping and recycling; nevertheless, it does not replace the need for certification by an approved institute.

- Stay Agile and Informed: Brands that stay engaged with regulatory updates and industry best practices will be better positioned to adapt and lead.”

Finally early collaboration across the value chain, whether that is with paper suppliers, adhesive experts, converters, recyclers or logistics partners, is non-negotiable.

“Early collaboration across the value chain is non-negotiable…”

According to Diana, working with an adhesives and coatings supplier like H.B. Fuller can help address key technical and scalability challenges. She highlights that support extends beyond product selection. Through APASS certification, H.B. Fuller conducts ISTA testing to verify that packaging can withstand the demands of e-commerce logistics. Their lab testing also helps brands validate the recyclability of fiber-based packaging.

“This proactive approach often accelerates time-to-market and ensures that the final packaging design is not only sustainable but also commercially viable,” Diana says.

Find out more about H.B. Fuller’s holistic approach to collaborating with its partners make the best adhesive choices for their e-commerce packaging needs.

Book your 30-minute meeting to find out more about H.B. Fuller’s holistic approach to helping its partners make the best adhesive choices for their e-commerce packaging needs.

This premium feature brings a completely new way for you to interact with our audience through a combination of collaborative editorial and premium promotion. An article written together between you and Packaging Europe’s content team, The Wider View will have a dedicated widget across all web pages & eNewsletter, and will link to a stunning, long-format web page put together by our design team featuring your graphics and branding. Carrying no other advertising, and pushing the limits of ordinary web communications, this is the ultimate digital content package

No comments yet