The market for glass bottles is estimated to continually thrive over the next few years. This especially holds true for the beer market but also for other categories, such as water, juices and carbonated soft drinks (CSD).

To keep abreast of this development and adapt to the ever more rapidly changing market and product trends, manufacturers expect new fillers, which offer high production flexibility, while at the same time guaranteeing maximum quality for their premium products. These needs can be met with Sidel’s EvoFILL Glass.

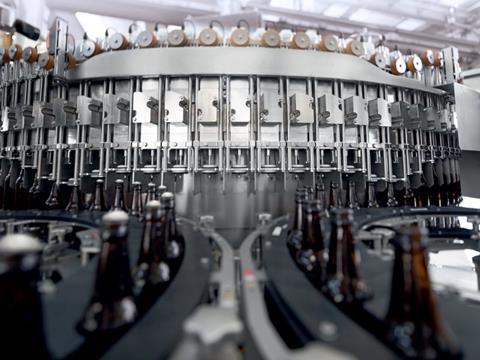

Glass bottles, with their high premium look and feel, call for a filling process that ensures matching qualities for both: the product inside and the packaging on the outside.

“EvoFILL Glass marks the latest milestone in Sidel’s filling portfolio. Product quality and an advanced level of versatility are more and more driving the development of our innovations. Our new solution is flexible, hygienic and sustainable, helping manufacturers to get ready for the upcoming challenges in premium drinks production,” declares Stefano Baini, Product Manager Filling at Sidel.

Top hygiene and precision: the keys to quality

EvoFILL Glass stands out with a number of features which guarantee high performance in the bottling process, as Mr. Baini explains.

“First, the filling level is controlled by level probes, ensuring very high accuracy and flexibility. Also, low foaming is secured by using swirling in the product deflection into the bottle for production efficiency.”

The solution’s highly hygienic design includes the “no base” architecture, the new drive system with servomotors, and – especially – its external beverage tank with the integrated small product chamber. Overall, these features ensure easy operations during production and maintenance, simultaneously helping manufacturers deliver the highest quality products to their consumers.

Maximum uptime through flexibility

EvoFILL Glass is able to hold the dissolved oxygen pick-up down to 10 ppb and to process a wide range of filling levels with no need for probe adjustments for enhanced uptime and top product quality. With 48 to 192 valves on the filling carousel, manufacturers can handle a broad range of speeds – from 25,000 to over 80,000 bottles per hour for 330 ml beer bottles – and bottle sizes from 200 ml up to 1 L.

“Very fast changeover times for different bottle diameters are made possible due to the re-designed handling parts, which are now lighter and smaller. With 98.5% efficiency and the possibility to manage an extensive spectrum of drink types and filling temperatures, EvoFILL Glass delivers an exceptional level of productivity,” Mr. Baini adds.

Crowning performance

The ultra-clean crowner manufactured by Sidel, with its open design and off-set crowning ring, adds further performance to the bottling process. The stainless-steel construction with its dedicated nozzles for the washing of the crimping area underlines the strict focus on optimal hygiene and product safety. The solution offers an upgraded washing system with three areas for maximum safety in case of bottle burst.

Sidel EvoFILL Glass is complemented by the Gebo OptiFEED® crown feeder, delivering quality and compliant crowns in a compact space. This is achieved via its integrated vision device, allowing unsuitable crowns to be spotted and seamlessly ejected, without stopping the flow.

“Whilst developing the OptiFeed solution, sustainability was high on the agenda of our design team, resulting in removing the need for air and thereby eliminating the risk of contamination that can occur during operation. Instead, mechanical discharge moves the crowns, keeping electrical power consumption to under 1kW. This creates a very smooth handling process and again improves hygiene, while reducing the environmental impact,” Mr. Baini concludes.

See EvoFILL Glass in action:

Find out more about Sidel’s EvoFILL Glass.

This content was sponsored by Sidel.