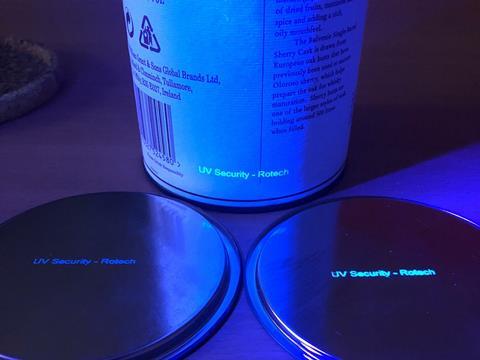

Coding and marking specialist, Rotech Machines, has introduced invisible ultraviolet (UV) thermal inkjet printing to offer customers enhanced product security and traceability, and to protect against counterfeiting.

Invisible to the naked eye, the special UV ink allows customers in all industries to apply discreet or invisible codes that can only be seen under ultraviolet light, reportedly making it difficult for fraudsters to replicate, particularly if the codes are placed in different areas by month or by batch.

Using Rotech’s high-resolution thermal inkjet technology, the UV ink can be printed in conjunction with standard batch codes, date codes, QR codes, serial number, brand labels or barcodes. Alternatively, it can be applied directly onto specific parts of the packaging or labelling in a range of formats.

Rotech says that applications for invisible UV printing are wide and varied; traceability and authenticity codes can be applied to pharmaceutical products, food packaging and alcohol, industrial parts, software, and high-value goods. For example, UV codes can be applied to medicines to show a secondary manufacture/expiry date of associated ingredients.

In industries where counterfeiting is a particular issue, the company argues that invisible UV codes can provide reassurance to distributors and end-users that the product is genuine. Manufacturers can place codes on to goods that are only known to them, switching the codes and their positions in relation to dates, batches or place of manufacture. This is particularly important for high-quality or high-value goods such as automotive parts or high-end brands.

“There is an increasing necessity to provide reassurance to both supply chains and end-users of product authenticity. Counterfeiting costs businesses millions of pounds of lost revenue every year so this simple to apply, low-cost technology can take security to new heights and make it almost impossible or impracticable for fraudsters to replicate,” said director of Rotech, Richard Pether.