Elisabeth Skoda speaks to several industry experts to shine a spotlight on just a few of the recent developments that showcase robots’ potential in the industry.

As a child back in the 1980s, movies like Star Wars shaped my perception of robots, and the prospect of robots like R2-D2 maybe being commonplace in the new millennium excited me. Reality has turned out to be somewhat more prosaic. However, robots have radically transformed manufacturing and the packaging industry.

Robotics is a huge field, spanning from large, big and fast industrial robots for manufacturing and medical robotics to consumer robotics solutions like vacuum cleaning robots and robotic pets.

“’Classic industrial robots behind safety fences will always exist. In car manufacturing, for example, robots are becoming more lightweight, flexible and will be more adaptable to different use cases. Combined with the progress in safety technologies, these robots pave(d) the way for first human-robot-collaboration scenarios. Human-robot-collaboration is on the edge of really taking off. Driven by the currently omnipresent vision of flexible and adaptable production of smallest lot sizes, humans and robots will work closer together,” says Dominik Bösl, head of robotics at Festo.

Cobots: challenges and solutions

The vision of robotic support is very old. The first moving statues – android-like mechanical ‘servants’ – were built in ancient Greece but building human-like support machines is not as easy as it may seem, as Mr. Bösl explains.

“We have seen a lot of progress in robotics over the last few years. Sensor technology allows the building of robots that can interact and collaborate with people. But there are challenges due to inertia. Physics cannot be cheated. When you move a large industrial robot around, you can only move very slowly to keep the arising forces under a certain threshold. Hence, lightweight construction is crucial.”

He goes on to state that new paradigms for interacting with robots will be necessary.

“Humans want to interact with robots like they interact with other humans: by demonstrating, showing or explaining what they should do. So, on the one hand, people want to work with smart, perceptive and understanding robots. On the other hand, humans always need to be in control of a robot – especially when it is used as a (very sophisticated) tool in production. Reconciling these very different requirements – increased autonomy vs. human control – will be a challenge.”

Maintaining productivity during the non-collaborative phases is an issue that needs addressing, and Staubli has found a solution.

“Often humans don’t collaborate with robots the whole day. In most of today’s applications, humans work close to robots, for instance for bringing parts or doing quality control. During the non-collaborative production phases, the robots have to be highly productive again. Thanks to its design and a unique package of modular SIL3 / PLe safety functionalities our TX2touch POWER-cobots offer a high productivity and safe collaboration,” says Jean-Marc Collet, marketing manager for robotics at Stäubli.

The next disruptive wave

Mr Bösl predicts that robotics and automation will have at least as much impact over the next half a century as the internet and mainstream IT had over the past five decades.

“We are still on the peak of digitalisation, but robotics will constitute the next, big, disruptive wave. As robotics is evolving, it is becoming more flexible, more accessible and easier to use. Hence, we will see a democratisation of automation technologies and a broader adoption of robotics. To achieve these goals, there are still some complicated tasks to be solved, e.g. robust object recognition in complex, unstructured environments or natural user interfaces, such as speech and gesture-based control or teaching by demonstration. Machine learning as well as artificial intelligence technologies will play a crucial role.”

Addressing staff shortages

Robots can play an important role in addressing recruitment problems, as Dan Rossek, marketing manager at Omron UK, explains: “Many manufacturers see robots as the ideal solution to problems such as difficulties in recruiting qualified, experienced personnel. Our recently opened Robotic Innovation Lab provides a platform that can be quickly configured to give an accurate representation of the impact that robots will actually have on the customers’ own production line, as well as allowing us to demonstrate how our other products can be quickly integrated to increase the benefits provided by the robots.”

He sees food handling as an important area for growth in robotics and highlights the importance of attracting more people to the engineering profession.

“We expect a boost in robotics and innovation areas such as primary food handling, which is generally still an intensive, manual process. We are looking at applications in that area and how we can develop solutions. Manufacturers face challenges due to reduced labour migration partly due to Brexit, so jobs for example in factories and agriculture are harder to fill. This means that people are more open to adopting new technologies, which then however involves the challenge to find the skilled workers to program and operate these systems. But work is being done to train the next generation of engineers, and we have seen a marked improvement.”

He highlights the importance of innovating in a smart, efficient way rather than deploying technology for the sake of it.

“The robot isn’t always the best solution for every application. It's about continual evolution of technology, which brings benefits and efficiency to manufacturing. I think as time goes on and people start adopting the technology more and more, they also start to see benefits.“

Handling food products

As a concrete application from the packaging industry, Alessandro Rocca, sales engineering director at Cama Group, highlights a growing popularity of multi flavour applications with customers from various food types, be it pet food or ice cream. Robots are ideal for this kind of task.

“Packaging applications have specific challenges, and often robots have to handle a lot of different products, such as biscuits, pet food, ice cream or frozen products. Robots have to know the flavour sequence and prepare everything to load the products into the package. The systems must be flexible enough to allow for recipe changes. At CAMA, we do not integrate third part robots, both the robots and software are our own design – better results are achieved with robots that are custom-made for packaging.”

He observes a bigger demand for the direct handling of unwrapped products, which requires robots with a gentle touch and even greater hygiene, so robots that are washable become a necessity.

Smart robots that move about the factory floor

Mr. Collet identifies mobile robots as a key growth area for the future.

“Robotics mobility is a logical step further into even more flexible and performant production. Therefore we launched our HelMo series of industrial mobile robots, which can autonomously move within the production premises and undertake different tasks defined by the company ERP.”

The HelMo mobile robot systems also help to link the production processes together reaching a higher production quality with lowering the number of parts in stock. For instance, HelMo can load a machine with raw parts and unload it, bring the manufactured parts to be cleaned and get them controlled by a measurement station before getting them packaged and ready to be shipped.

Industry 4.0 and machine learning has expanded what robots are capable of doing in production.

Robots are becoming more and more crucial for production, as Mr Collet explains.

“Thanks to their controller’s open architecture and high connectivity, robots can directly be linked to ERP systems to fully support all the production batch changes with the highest traceability. They are also able to gather data and detect patterns, modelling them to get more predictive scenarios in order to prevent production downtime and secure the investment with dedicated preventive maintenance actions.”

Robots, not just in the packaging industry, are getting smaller, lighter, more energy efficient and will be more flexible and adaptable to different use-cases, as Mr. Bösl observes.

“There will still be ‘traditional’ industrial robots – big, fast, accurate but also potentially harmful to humans if not behind a safety-fence. But modern robotic solutions will become increasingly easy to use, easy to set up and operate; collaborative robotics is on the rise and will also find its place in packaging and – especially – commissioning. Humans and robots working side by side, e.g. in warehouses, will be a common sight.”

When harnessing the power of IT and connectivity, robot behaviour can be simulated before they actually end up in the factory. Mr. Rocca explains.

“We can provide our customers with machine simulation so that they can see in advance what will happen in the field. Furthermore, augmented reality and digital twin technology give a real view of the machine remotely, great for servicing and real time interaction.”

Innovation with bionics

Mr. Bösl underlines the importance of learning from evolution.

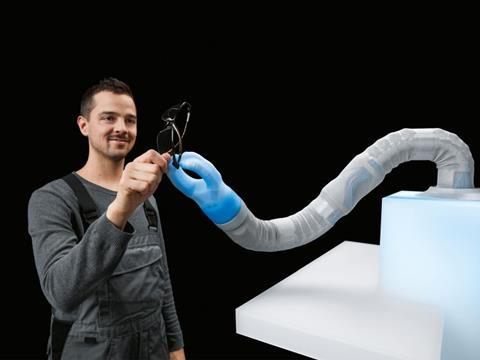

“Bionics is a great way to learn from nature. Evolution has put millions of years of trial and error into finding the perfect solution for particular problems. By analysing and understanding these solutions, we can find inspiration for some of the hardest problems in engineering. Unfortunately, that does not mean that we can ‘simply’ copy nature. Replicating an Elephant and putting such a ‘Robophant’ into a manufacturing plant does not make sense. Understanding the particular advantages of the Elephant’s trunk, though, could lead to completely new kinematics for flexible, adaptable, lightweight robotic ‘arms’ with many degrees of freedom – like Festo’s Bionic Softarm.”

He predicts that robotics will continue to disrupt.

“This ‘robotic revolution’ has already begun in structured environments, i.e. manufacturing and production. Applying artificial intelligence and machine learning, robots will get ‘smarter’ and more perceptive. New user interaction paradigms, like speech control or teaching by demonstration, will make adoption easier. We will experience the same democratisation in robotics over the next half a century that has already happened in computer technology. Robots will become commodity and can be used by anyone. Festo will focus on developing robotic solutions that help, enable and augment human capabilities but will not replace them.”

Finishing on that note, maybe I will see R2-D2 robots on the streets in my lifetime after all!