As part of our Innovation Spotlight series, Control Union explains how integrated third-party certification can turn regulatory pressure from legislation such as the EU’s Packaging and Packaging Waste Regulation (PPWR) into measurable value.

The EU’s Packaging and Packaging Waste Regulation (PPWR) entered into force on 11 February 2025, with most provisions biting from 12 August 2026. For brand owners, CSOs and converters, the next 12 months will decide whether packaging becomes a compliance liability or a competitive edge.

Europe’s stricter rules for packaging

Europe generates 186.5 kg of packaging waste per inhabitant each year, up by 21% since 2011. Plastic alone accounts for 16 million tonnes, yet only 41% of that plastic packaging is recycled, despite targets rising to 65% by 2025 and 70% by 2030.

The PPWR raises the bar further:

- Mandatory recyclability and ‘design for recycling’ rules for all packaging by 2030

- Mandatory recycled content (RC): minimum percentages rise in 2030 to 10-35% and to 25-65% by 2040

- PFAS ban for food-contact packaging from 12 August 2026

- Labelling requirements and digital tool implementation, e.g. Digital Product Passport (when packaged product is covered by Regulation (EU) 2024/1781)

Add in the Single-Use Plastics Directive, which already requires a 25% rPET share since this year, and the stakes are clear: failure to substantiate recyclability claims will carry hefty penalties and could erode brand trust on the European market.

Certifications: a structured response to regulatory requirements

A portfolio of independent packaging and plastics certifications offers a practical way to address the core compliance challenges posed by the PPWR. These systems align directly with the regulation’s key articles, providing businesses with verified documentation and traceability across the supply chain.

Recyclability validation and design for recycling

Relevant articles:

- Article 6: All packaging placed on the market must be recyclable, with recyclability performance grades (A, B, C) becoming mandatory from 2030 and stricter from 2038.

- Article 6(4): Requires design for recycling criteria and recyclability performance grades to be established.

- Article 6(5): Introduces a methodology for assessing whether packaging is ‘recycled at scale’.

How certification helps:

- Certification schemes assess packaging against recyclability criteria aligned with EU methodologies.

- They provide documented proof of recyclability grades and design conformity.

- They support manufacturers in meeting recyclability thresholds and preparing for recyclability audits.

Recycled content verification

Relevant articles:

- Article 7: Sets mandatory minimum recycled content levels for plastic packaging (10–65% depending on type and year).

- Article 7(6): Requires technical documentation to demonstrate compliance.

- Article 7(8–10): Mandates the development of methodologies for calculating and verifying recycled content, including third-party audits.

How certification helps:

- Certification programs verify mass balance or physical traceability of recycled content.

- They ensure compliance with post-consumer waste sourcing and processing requirements.

- Third-party audits provide the independent verification required under Article 7(10).

Chemical safety and PFAS restrictions

Relevant articles:

- Article 5(5): Bans PFAS above the limit values in food-contact packaging from 12 August 2026.

- Article 5(1–4): Requires minimization of substances of concern, including heavy metals and microplastics.

How certification helps:

- Certification schemes include chemical screening and documentation reviews.

- They help businesses demonstrate compliance with PFAS thresholds and other substance restrictions.

- They support the creation of technical files required under Article 5(6).

Chain-of-custody and traceability

Relevant articles:

- Article 6(5)(b): Requires a chain-of-custody mechanism to prove that packaging is ‘recycled at scale’.

- Article 12: Introduces labelling and digital data carrier requirements for packaging traceability.

- Article 45: Requires producers to demonstrate extended producer responsibility (EPR) compliance.

How certification helps:

- Certification bodies implement chain-of-custody systems that track materials from source to final product.

- They help producers meet EPR obligations by verifying material flows and recovery.

Conformity assessment and technical documentation

Relevant articles:

- Articles 15–18: Define the obligations of manufacturers, importers, and distributors to ensure packaging complies with Articles 5–12.

- Article 38: Requires conformity assessment procedures.

- Annex VII: Specifies the required technical documentation.

How certification helps:

- Certification bodies conduct conformity assessments aligned with EU requirements.

- They generate audit reports and technical documentation that manufacturers can use to demonstrate compliance.

- They reduce the administrative burden by consolidating multiple compliance checks into one audit.

Support for labelling and digital product passport

Relevant articles:

- Article 12: Requires harmonized labelling and digital data carriers for recyclability, reusability, and recycled content.

- Article 6(4)(a)(v): Allows for restrictions on substances that hinder recyclability, which must be documented.

How certification helps:

- Certification schemes provide verified data that can be embedded in digital product passports.

- They ensure that claims made on packaging (e.g., ‘recyclable,’ ‘contains 30% recycled content’) are substantiated and legally defensible.

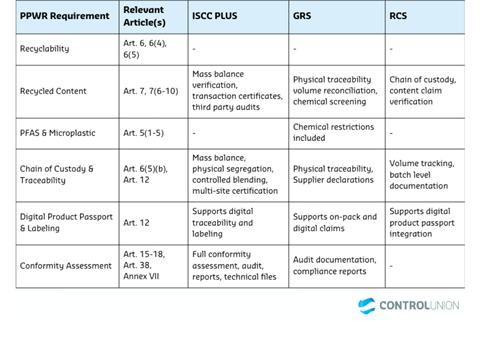

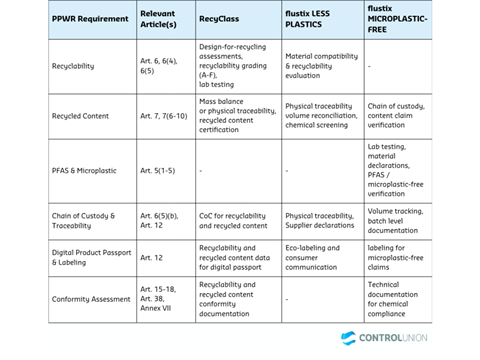

PPWR Compliance Matrix: mapping selected certification schemes to regulatory requirements

By bundling several certifications into one combined audit, brand owners can typically half auditor costs. A certification body with global reach can provide additional efficiency that scales across borders. European headquarters can get their international converters audited under PPWR-aligned systems, smoothing compliance from initial pack design all the way to final distribution.

Conclusion

The PPWR window is closing fast. Third-party certification can turn the regulatory countdown into a business advantage and protect your brand, lower costs and substantiate your sustainability promises to stakeholders. Engage a trusted and reliable certification body like Control Union that can combine audits and provide their certification services for your whole supply chain.

This content was sponsored by Control Union.