Xaar has announced its new Ultra High Viscosity Technology, said to deliver flexo print quality, reduce cost per print and minimize ink absorption into corrugated surfaces.

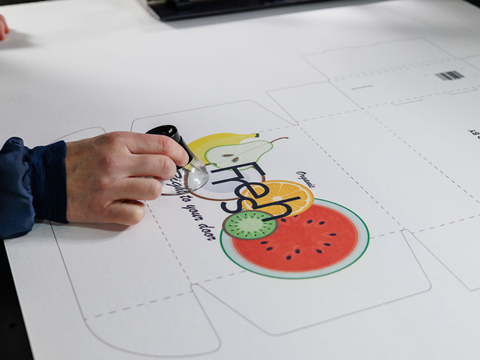

The company says that due to the new technology, its Aquinox printhead can jet fluids of up to 1000 centipoises (cP) at ambient temperature (approx. 100 cP at jetting temperature), enabling chemists to develop inks that minimise ink absorption into corrugated surfaces, aiming to ensure visible appeal and durability for corrugated packaging. The new water-based high viscosity inks were developed by Nazdar.

Xaar states that by absorbing less ink into the board, the same print quality is achieved with less ink, enabling faster printing and significantly reducing production costs as well as the total cost of ownership. With less substrate penetration, high-viscosity inks can apparently remove the need for primers, reducing drying energy and fluid usage and resulting in brighter prints on uncoated and unprimed corrugate boards.

According to Xaar, independent research conducted by the Welsh Centre for Printing and Coating at Swansea University demonstrated that using Xaar’s Ultra High Viscosity Technology increases colour density by up to 60%. The researchers also found that by reducing water in the inks, less energy is consumed in the drying process, lowering operational costs.

In similar news, DTM Print recently introduced its new LX4000e Color Label Printer, said to reduce downtime, ensure maximum productivity and give users more control over their printing operations. Manufactured by Primera Technology, the LX4000e features individual ink tanks and a reusable thermal inkjet printhead.

This month HP unveiled HP ThermaCore, its thermal inkjet (TIJ) technology designed to improve efficiency, meet global coding standards and reduce operational costs in coding and marking applications. Apparently, the new technology can achieve three times the throw distance, twice the print swath, and twice the printing speed of previous TIJ generations.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet