It’s that time of year again! At last night’s sold-out awards dinner full of industry leaders, the winners of the Sustainability Awards 2024 – the “Nobel Prize” for sustainable packaging innovations – were announced.

In no particular order, here are our winning entries.

First up was the Best Practice award, which went to Gemini Corporation for its GemCorp Recycling initiative.

GemCorp was founded to establish a formal collection network and improve the livelihoods of informal waste reclaimers. Its many efforts include hosting clean-up projects in rural villages across India; installing baling machines on the premises of reclaimers and aggregators, free of charge; helping informal waste workers open bank accounts and create government IDs; ensuring access to clean drinking water, safety, and sanitation; and helping ban child labour.

As it joins forces with waste workers, GemCorp aspires to help develop safe practices, provide relevant training and protective gear, and streamline collection methods. Every year, it collects and recycles over two million tonnes of waste and saves 2.4 million tonnes of CO2.

It also contributes to shifting perceptions about waste, recycling, and the environment and provides high-quality, cost-effective plastic recyclate to reduce the demand for virgin plastics. Meanwhile, its blockchain-based ‘ReMake’ application plans to unlock end-to-end traceability, transparency, and circularity in the recycling value chain.

Ardagh Glass Packaging took home the Climate award for its NextGen Furnace. The facility in Obernkirchen, Germany, uses electrodes to melt glass with direct electrical heating, thus replacing fossil fuel with renewable electricity. In turn, it expects to reduce Scope 1, 2, and 3 carbon emissions by as much as 69% for every 330ml amber glass bottle produced.

While the facility currently operates at 60% electrical heating, Ardagh Glass Packaging plans to transition into 80% renewable electricity and 20% gas – and, depending on the production mix, save up to 45,000 tonnes of carbon every year compared to a conventional furnace.

It also plans to reduce its required energy consumption by using up to 70% recycled glass cullet, and expects to reduce CO2 emissions by 5% for every 10% increase in cullet used. A life cycle analysis (LCA) reveals that every 330ml bottle reduces 97.1g of CO2 across Scope 1, 2, and 3 emissions.

Every glass bottle produced at the NextGen furnace is set to be completely and infinitely recyclable.

For repurposing PET blisters and trays – traditionally considered to be low-quality sources of recyclate due to their complex, multi-layer construction – into a 100% PCR, circular PET film sourced from household waste, Henkel won the top prize in the Driving the Circular Economy category.

The film comprises more than 80% recycled PET tray, all of which are sourced from German household waste. The final film is applied to the blister pack for Henkel’s WCFrisch ProNature WC cleaning product.

This process diverts recyclable waste away from industrial incineration, conserves materials, reduces emissions, and prevents downcycling into non-bottle applications.

To achieve this innovation, Henkel has fine-tuned its sorting and washing processes, including the development of NIR sorting strategies to recover PET trays from the rejects of the PET bottle stream – thus creating a secondary stream at industrial scale.

Amazon and Mondi were our E-Commerce category winners. Their 100% recyclable and flexible paper-padded envelope for e-commerce deliveries is designed to phase out plastic-based bubble-wrap padding without compromising on shock absorbance and product protection.

This innovation utilizes the same paper as Amazon’s existing delivery bags, alongside padding from corrugate – a move set to secure the pack’s resilience and keep products safe in transit. The flexibility of its open-flute padding helps the pack fold around the product’s shape, preventing it from shifting inside the mailer and negating the need for void fillers.

The envelope is lighter than cardboard alternatives, so it reduces carbon emissions in the manufacturing and delivery processes. It comes in three sizes and is disposable in European household recycling streams.

Meanwhile, Brook + Whittle took home the trophy in the Recyclable Packaging category for GreenLabel BlockOut, its APR-recognized recyclable, light-blocking shrink sleeve.

Since coloured PET is considered a low-value resin, GreenLabel BlockOut is designed to enable manufacturers to transition into clear PET without compromising on light-blocking performance. This solution is able to block up to 99% of light from 200nm to 900nm.

At the same time, it achieves a 100% sorting rate through NIR sortation equipment when applied to a clear PET bottle (according to the company’s MRF studies), thus keeping plastic out of landfill.

Reclaimer studies place the solution’s colour sort between 80% and 93%, with de-labelling equipment that partially removes the shrink sleeve further increasing these figures. Brook + Whittle emphasizes that such technology ensures a cPET shrink with a deinking and filterable light-blocking coating can be fully recycled in the PET stream.

Upfield’s plastic-free, oil-resistant, and waterproof wet fibre moulded tub for plant-based spreads won the Renewable Materials award. This solution uses paper from a PEFC-certified supplier and has received Conventional Plastic Free Certification.

Since it is decorated with MCC Verstraete and Pagès Group’s Molded Fiber Labelling, the pack is mono-material and therefore recyclable. It does not have a plastic liner, meaning it can be cleaned, dried, and recycled alongside paper and cardboard household waste, as verified by a leading European recycling company.

The pack is described as the first oil-resistant paper tub for plant-based spreads. Emsur has also contributed to its development by applying a tamper-evident feature made of paper.

Upfield plans to replace up to two billion plastic tubs with paper-based alternatives by 2030, thus phasing out over 25,000 tons of plastic waste annually.

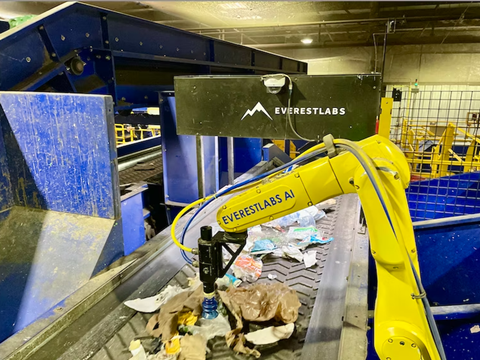

And in the Machinery category, EverestLabs’ RecycleOS, an AI-powered robotics solution for material recovery facilities (MRFs), was announced as the winner. RecycleOS analyzes the waste stream coming into a facility and recovers twice to three times the amount of material that traditional sorting methods can.

Reaching an accuracy of over 95%, this solution is set to keep recyclable materials within a circular economy and enhance a plant’s efficiency by 30-50%. It can also analyze the value, volume, and types of materials entering and exiting a plant – providing the necessary data to improve operations and increase material recovery – while helping keep suppliers accountable with traced and verified feedstock supply.

The system can be installed into existing recycling lines, including inclined and cleated belts, and is therefore less expensive to implement.

Moving into the Pre-Commercialized categories:

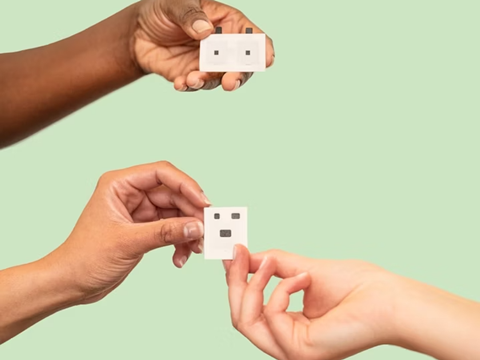

The Pre-Commercialized Climate award went to PulpaTronics for its recyclable, metal-free, chipless RFID tags. Instead of a metal antenna, these solutions laser-induce a carbon-based conductive material onto paper and store information in the geometric pattern of the conductor instead of a microchip.

Therefore, the tags negate the need to mine metal, cut down on the resources required to produce them, simplify manufacturing, and streamline recycling.

They are set to halve the price of conventional RFID tags, as they cut down on transportation, material, and energy-related expenses. Since they do not rely on a global supply chain, they are set to create more equity between high- and low-income countries.

The chipless tags can be recycled six or seven times via existing recycling systems before being composted at end-of-life. They are set to reduce CO2 emissions by 70% every year and save 24 tonnes of CO2 for every 10,000,000 items tagged.

In the Pre-Commercialized Driving the Circular Economy category, Husky came out on top for its designed-for-circularity PET closure, intended for use in still water packaging.

Manufactured from bottle-grade PET, it is fully compatible with existing PET recycling streams, which simplifies collection, avoids stream contamination, and increases recycling yield. Therefore, it hopes to increase the availability of recycled PET within the economy and facilitate a circular transition.

The closure enables further opportunities for lightweighting than conventional solutions due to its material properties. It can also be tethered in line with EU legislation.

To overcome the challenges to sealing and tamper evidence posed by PET’s rigidity, Husky has innovated a new sealing system and technique that achieves 100% repeatable and obvious proof of tampering attempts.

John West Foods’ Ecotwist minimal multipack packaging received the Pre-Commercialized Recyclable Packaging award.

Aiming to avoid 65 tonnes of PET plastic shrink wrap in John West’s ‘tuna tower’ formats every year, Ecotwist replaces plastic and carton wrap with a ‘naked’ multipack joining five steel cans of tuna with a recyclable aluminium foil sticker.

This ‘Smartstrip’ is perforated, meaning consumers can twist and remove the sticker with ease. It has been independently verified as fully recyclable and can be recycled in one piece with the steel can via kerbside recycling in the UK.

The solution was developed in partnership with Touch Design, CCL Label, Schubert Packaging Systems, Karville, Secma Cabon, and Concept PG.

John West has also reduced the amount of metal within its tuna cans, with the new design weighing 4g less; it has also reduced the amount of sunflower oil, spring water, or brine used to preserve the same amount of tuna. The move is hoped to save an annual total of around 200 container loads from production factories in Ghana and the Seychelles to the UK.

Our Pre-Commercialized Renewables winners were Avery Dennison and Bioenzymatic Fuel Cells (BeFC). Their organic battery based on Avery Dennison materials replaces non-disposable coin and button cell batteries with a compostable and/or recyclable energy solution for microelectric IoT applications (e.g., smart consumer labels).

The biofuel cell is made from paper, carbon, and enzymes and converts sugars and oxygen into electricity. In doing so, it reduces demand for the rare-earth materials and toxic electrolytes used in conventional battery technologies, substituting them with organic and widely available alternatives.

The battery is thin, flexible, lightweight, and low-cost. It resists water and grease while remaining permeable to oxygen and securely bonding the enzymes inside the biofuel cell for operational longevity.

This solution expects to unlock data opportunities without the challenges associated with traditional battery disposal.

As ever, our Readers’ Award category was chosen by Packaging Europe subscribers instead of the expert Sustainability Awards judging panel. This year, you gave the award to Vytal and its fully digital experience for reusable food and drink containers.

A full-scale pilot took place among the 80,000 participants of the OMR Festival 2024 in Hamburg. Using individually traceable cups and food containers optimized the efficiency of the reuse system, while its unmanned return processes simultaneously reduced the strain on venue staff and cut down on the time consumers spent waiting or at checkout.

Finally, the Outstanding Contribution trophy was awarded this year collectively to the GreenBlue team, after judges nominated several different individuals at the pioneering non-profit organization based in the USA.

GreenBlue has played a pivotal role in facilitating value chain coordinated progress across the packaging value chain in North America, initiating transformative projects such as the Sustainable Packaging Coalition and the How2Recycle label.

Last but by no means least was the Overall Winner - the crowning moment of the entire event. this was chosen from the commercialized nominees with the most votes from the judging panel. Once again, Upfield emerged victorious with its wet moulded fibre tub.

As the sun starts to set on another Sustainable Packaging Summit, we’d like to congratulate every finalist shortlisted for an award. Each nominee is spearheading important work, whether or not they are returning home with a trophy, and we look forward to seeing the same passion for sustainability carry over into 2025.

We also extend our warmest thanks to everyone who joined us at the event, whether as a sponsor, speaker, exhibitor, or attendee. The Summit would not be what it is without the warmth, enthusiasm, and expertise each one of you brought to the Beurs van Berlage this year.

All our interviews with the finalists can be found here, and you can keep up to date with all things Sustainability Awards – including the latest news and updates – under our dedicated tag.

Submissions for next year’s awards will open in January 2025. Find out more about the application process here.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet