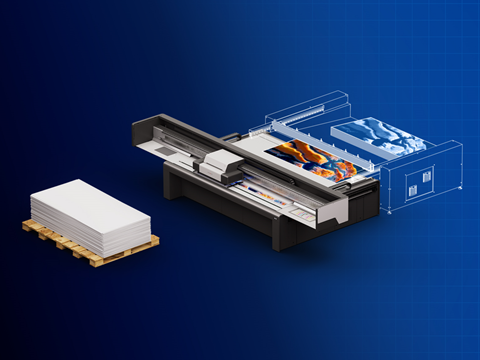

swissQprint presented an automation option at drupa 2024, designed to maintain high productivity in flatbed printing by relieving operators of unloading tasks.

The company says its unloading option was presented in response to customer demand for automating printing processes while preserving flexibility. The new automation module removes processed media up to 3.2×2 metres from the flatbed printer’s table, aiming to ease the burden of handling large runs efficiently. Loading continues to be done by hand.

The company emphasizes that the new unloading option preserves printer versatility and accessibility. Special applications, short runs and roll jobs can all be done as before, because the unloading option undocks from the printer any time.

swissQprint gathered initial customer feedback as part of the development process. “drupa is now the perfect opportunity to show the conceptual study and collect broad-based feedback that will go into final development,” said Carmen Eicher, chief of sales and marketing officer at swissQprint. Once tailored to market needs, the finished product should be available in 2025.

The unloading option was part of a range of developments shown by swissQprint in live demos at drupa 2024. First was Kudu, the flatbed printer used to present the unloading option. Also on the stand was Karibu 2 and swissQprint flagship Nyala. The Swiss manufacturer added that a 36-month warranty on new machines is applicable to all models and configurations since April 2024.

Also at drupa was digital front ends (DFEs) and workflow solutions provider Fiery, attending with a range of printing technologies for packaging, direct-to-film, and industrial applications, among others. Fiery’s specialty production printers utilize AI, cloud, and automation technologies in an effort to achieve high-quality colour, precision, efficiency, and profitability.

Digital embellishment provider Scodix recently unveiled its first AI (artificial intelligence) tool - Scodix AI - ahead of drupa 2024, aiming to address growing demand for automation tools among print providers and designers. Hoping to help brands gain attention in a crowded marketplace, the company says its technology uses learnings from databases of Scodix-enhanced pages to automate the embellishment design process, analyzing designs before suggesting intelligent design choices.

If you liked this story, you might also enjoy:

How are the top brands progressing on packaging sustainability?

The ultimate guide to global plastic sustainability regulation

No comments yet