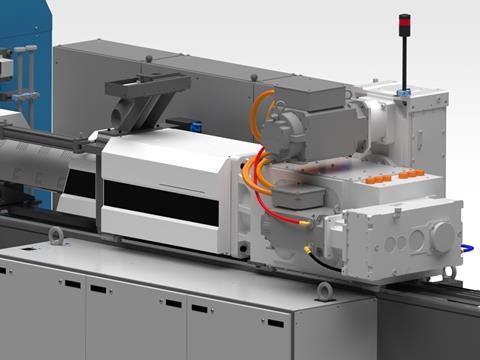

Netherlands-based Stork IMM has extended its injection moulding machine range with the launch of a new all-electric line.

Stork says that the new offering – scheduled to be showcased at the upcoming K show – boasts lower energy consumption, an innovative rack-and-pinion drive system, and highly customized process tailoring for a range of applications in thin-wall food packaging and industrial paints/buckets.

The company further describes its latest machine as being capable of creating highly flexible, customized solutions for its customers by pairing clamping units from 250 up to 700 tons with a range of injection units with screw sizes from 45 up to 84 mm.

“This machine extension satisfies growing customer demand for high-performance injection molding machines that meet sustainability goals for the packaging market,” comments Gert Boers, CEO of Stork IMM.

“This development reaffirms our commitment to delivering the latest technology that will support a circular economy.” Stork continues to focus on high-performance features including high output, maximum uptime, and a highly favorable total cost of ownership.

Stork claims that its new all-electric units “achieve 15% greater energy savings compared to similarly specified hybrid machines” and operate at injection speeds suitable for thin-wall packaging applications.

An element of the machine, the heavy-duty rack-and-pinion drive, is described as being highly rigid, energy efficient, while also providing reduced wear and longer life. The drive, Stork says, provides higher speed forces for the clamp and injection units compared to ball bearing and spindle drives.

The all-electric units also feature a breaking energy feedback system whereby recovered energy can reportedly be fed back into the customer energy grid.

If you liked this story, you might also enjoy:

Reuse vs. single use – which is better for the environment?

Sustainable Innovation Report 2025: Current trends and future priorities

What can the world learn from South Korea’s world-leading performance in plastics circularity?

No comments yet