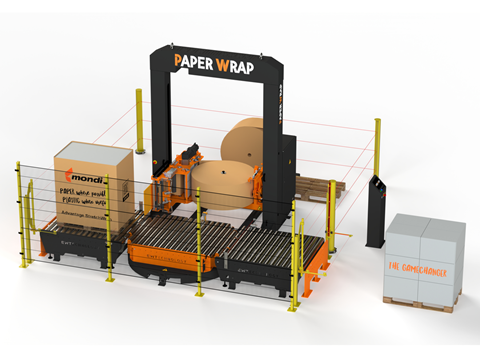

Ranpak has integrated PaperWrap’s pallet wrapping machines, which replace plastic stretch film with a kraft paper alternative from Mondi, into its portfolio – aspiring to enhance efficiency and lower greenhouse gas emissions in transit.

Three PaperWrap models are available: semi-automatic stand-alone units, fully automatic standalone machines, and fully automatic line integration systems. Each is set to help cut down a customer’s carbon footprint and contribute to its sustainability targets.

Apparently, the machinery fits ‘seamlessly’ into customers’ existing operations, including warehouse layout, ergonomics, and throughput demands, with European customers like IKEA said to have adopted these solutions previously.

PaperWrap’s machines are designed to accommodate Mondi’s Ad/Vantage Stretch Wrap kraft paper, which claims to be free of plastics and coatings – instead utilizing ‘renewable’ wood and ‘responsibly sourced’ fibres. As such, it is believed to be fully recyclable in existing paper waste streams.

Furthermore, the paper is described as both puncture-resistant and tension-absorbing. This reportedly enables customers to transition into paper without compromising on performance when transporting goods.

One reel of Ad/Vantage StretchWrap is thought to wrap up to 750 pallets, while a peer-reviewed independent life cycle assessment suggests that it emits 62% greenhouse gas than virgin plastic stretch film, and 49% less than plastic film containing 50% recycled content.

“To successfully introduce PaperWrap machines to the market, it is essential to involve the right partners,” said Jurre Hesseling, responsible for sales activities at PaperWrap. “We have found this partner in Ranpak.

“From our very first conversation, it became clear that we share a common vision and ambition in the field of circularity. Our collaboration is a critical step toward addressing the challenges of a sustainable industrial packaging future.

“We see immense opportunities to make a difference together through innovation, design, and reducing carbon footprint—helping more customers in a sustainable way and empowering more people to reduce their environmental impact.”

“At Ranpak, sustainability is at the core of everything we do,” added Omar Asali, chairman and CEO of Ranpak. “This new partnership with PaperWrap represents a significant milestone as we continue to evaluate the most sustainable materials possible and deliver resources that will help businesses transition away from single-use plastics.

“Together, we are driving the future of sustainable packaging and creating a positive impact for generations to come.”

Back in May 2023, Mondi joined forces with Silbo to replace its plastic stretch film wrapping for pallets, with the latter installing EW Technology’s PaperWrap technology at its plant in Żory. Later that year, Robopac also developed a paper wrapping machine compatible with Mondi’s Advantage StretchWrap, set to help customers phase unnecessary plastics out of their pallet wrapping operations.

Ranpak has also made other developments in pursuit of more sustainable packaging operations, including its recent announcement of three integrated solutions for applying recyclable and biodegradable pads or void fill to e-commerce and industrial packages. Said to combine automation and protective paper technology, the machines are designed to lessen the amount of labour and training required of human operators.

Meanwhile, European Plastics Converters (EuPC), IK Industrievereinigung Kunststoffverpackungen (IK), and Elipso have signed a document critiquing the Packaging and Packaging Waste Regulation’s reuse regulations for plastic pallet wrappings and straps in transport applications. In their view, such packaging already contains post-consumer recyclate, is fully recyclable, and cannot yet be replaced by an effective alternative material.

If you liked this story, you might also enjoy:

Reuse vs. single use – which is better for the environment?

Sustainable Innovation Report 2025: Current trends and future priorities

What can the world learn from South Korea’s world-leading performance in plastics circularity?

No comments yet