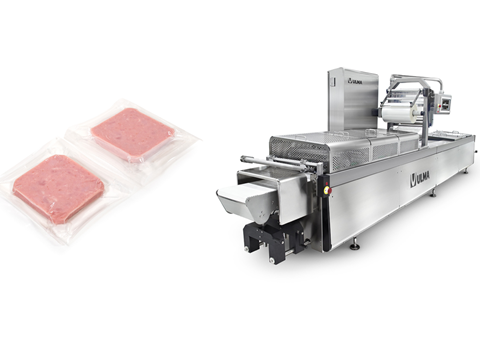

ULMA Packaging has launched its Width-Flex technology for thermoforming machines, said to reduce film waste by up to 80%, improve efficiency and minimize operational downtime.

Designed to tackle the challenges of format variability, Width-Flex has a motorized bottom web width adjustment system, said to enable ‘seamless changes’ in reel width. ULMA states that this minimizes operational downtime and optimizes packaging unit costs, suitable for industries that rely on thermoformed packaging.

Apparently, Width-Flex has the capability to reduce film waste by up to 80% by adapting the machine’s width to the specific required format, eliminating the necessity for oversized reels and ensuring minimal material waste across all packaging formats.

The system also includes an operator interface with standard operating procedure (SOP) guided changeovers displayed on the machine screen, reportedly allowing users to complete format changes in under 45 minutes. ULMA adds that businesses can adjust both the machine width and advanced settings, removing the need for extra thermoforming machines tailored to different formats and maximizing factory floor space.

Last summer GEA announced its ‘entry-level’ PowerPak 1000 thermoformer machine for packaging meat, meat substitutes, poultry and cheese, with functions previously reserved for machines in the higher performance range. The machine’s features include flexibility in pack size and reduced plastic consumption, targeting companies looking to move away from traditional methods such as vacuum chamber machines.

German startup Watttron revealed its new thermoforming process ‘cera2heat’ in December 2024, said to reduce material use by up to 50% compared to traditional processes. Apparently capable of consistently producing uniform, thin-walled packaging shapes, the process has precise temperature control of individual ‘heat pixels’ and can eliminate common packaging defects including faulty shapes.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet