The digital transformation of supply chains has become an important element in improving the resilience and traceability of physical goods, says Terrance Barkan of the Graphene Council. He reports that AIPIA member Advanced Material Development (AMD) is innovating a range of highly conductive nanocarbon-based inks to provide compostable alternatives to traditional metal-based UHF RFID technologies used in supply chains.

The InnovateUK-funded consortium, SecQuAL, is focused on the food sector and how RFID systems can ensure food traceability and quality. AMD has produced a series of digital and intelligent packaging demonstrators highlighting consumer interactivity and backend material resource planning (MRP) functionality, simulating production, distribution and sales environments through combinations of QR codes, barcodes and UHF RFID.

AMD says it is very conscious of the need to create new technologies that don’t add excessive recycling burdens to the end users. They see clear benefits in technology that could ensure recyclability and traceability with the use of novel nanocarbon antenna that provide identification functions through integration with UHF RFID via labels or direct printing.

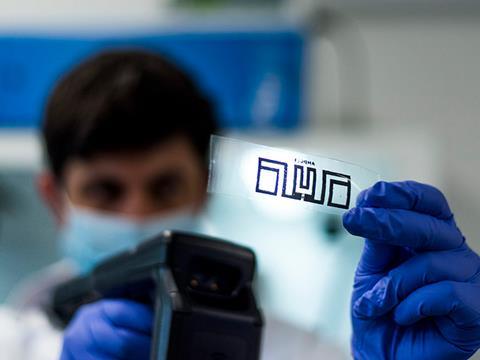

The AMD development team is currently working with partners on upscaling this technology and its implementation into individual supply chains, including meat and fresh produce production and distribution. Its prototype RFID tags can be printed onto substrates such as paper, printed as labels and loops or printed directly onto packaging, providing flexibility of deployment where required, it claims.

By several estimates, UHF RFID is reaching over 20 billion items annually (IdTechEx) and as such, modern packing and aggregate labelling must present different functions and appearances to consumers, supermarkets, logistics companies, auditors and producers, says the company.

It believes traceability of goods is becoming critical for companies to show their ESG credentials; digital technologies such as QR, barcodes and RFID enable the linking of objects and locations through harmonised standards such as GS1 EPC (electronic product code) systems and the TDS 2.0 standard. The standards are designed to guide interoperability between scanners, barcodes and tags, software systems, vendors and clients.

This article was created in collaboration with AIPIA (the Active and Intelligent Packaging Industry Association). For a full update on active and intelligent packaging, come along to the AIPIA World Congress (co-organized by Packaging Europe) in Amsterdam on 14-15 November. The only smart packaging event covering the entire technology spectrum, the World Congress is a meeting place for the global active and intelligent packaging industry where brand owners, innovators, and other stakeholders can network and see and discuss the latest trends and innovations. Register to attend here.

No comments yet