This publication has consistently argued that more LCA/carbon footprint data is required to fully understand the climate implications of certain sustainability trends within the packaging industry.

In light of this, a recent study carried out by the Research Institute of Sweden (RISE) in partnership with Pro Carton, the European Association of Carton and Cartonboard Manufacturers, has reported that 326kgCO2e is emitted per tonne of converted cartons manufactured by the carton packaging industry in Europe.

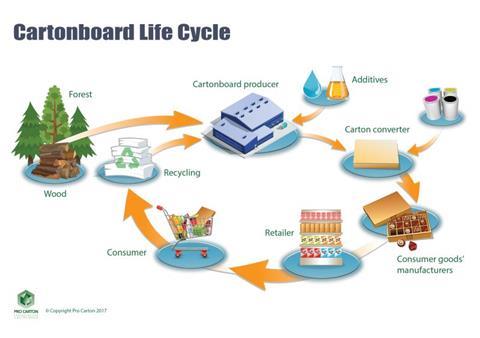

RISE reportedly used a carbon footprint methodology that considers all emissions and removals associated with forest-based products, including aspects unique to the forest industry’s value chain. Pro Carton says that this research covers the cradle-to-grave carbon impact, taking account of both fossil GHG emissions arising from non-renewable sources, such as oil, coal and biogenic GHG emissions and those from renewable sources, such as plants and trees, and removals and emissions from direct land-use change.

The partnership argues that their study’s methodology is significantly different and broader than any previously used and is in-line with the latest CEPI and CITPA guidelines. The new figure cannot, therefore, be directly compared to previous studies. However, a comparison was undertaken using the old methodology which reportedly showed that on a like-for-like basis the industry had improved its carbon footprint by approximately 9% since the last report in 2015.

Tony Hitchin, General Manager of Pro Carton, says: “The new methodology presented in this report is comprehensive because it fully recognises the carbon impacts of carton packaging from forest to converted cartons. It is part of a wider Environmental data report and this information will be made available to LCA experts for their own analysis. Cartons are one of the most eco-friendly forms of packaging and we are delighted that the new carbon footprint figure further endorses that.

It is important to note, however, that average footprint and relative footprints of different materials in specific packaging applications are two different considerations. The impact of using a particular material will increase or decrease based on distances between production and delivery, the type of energy used in a specific instance, and the effect it has on the footprint of the packaged goods