Neopac will feature its new SpringTube™, a packaging solution for skin health products, at Pharmapack 2020, Stand C52. Developed by subsidiary 3D Neopac, the tube is specially designed to maintain its shape while delivering a host of additional benefits for consumers, brand owners and manufacturers.

Featuring a tamper-evident, push-on PE flip-top cap, the printer-friendly SpringTube™ can be decorated via digital, flexo or metallic foil processes. For product protection, an ethylene vinyl alcohol (EVOH) barrier preserves oxygen-sensitive formulas, and helps extend the shelf life of beauty and personal care products.

Available in fill volumes from 40-300ml, 3D Neopac says its SpringTube™ offers differentiating benefits to multiple stakeholders. According to the company, these include:

- Brand owners – The direct-to-print SpringTube™ offers brand owners an array of customizable design options like digital print for details in skin/faces and nature, flexo print and metallic foiling. SpringTube™ can feature coloured or metallized caps and offers high flexibility properties to replace existing label tubes. SpringTube™ can be individualized down to the unit level by variable data printing, allowing brands to create on-package marketing activities such as sales promotions, competitions, collectables or games.

- Consumers – Since the SpringTube’s composition maintains the tube’s shape during use, the solution shows well both on shelves and, in forums such as online demos, on camera. The tube’s easy-open caps, which also are available with a tamper-evident feature, provide additional safety and user-friendliness. In addition, individualized coding can be applied to each tube for consumer participation in competitions, local events, special rebates or collector series.

- Manufacturers – SpringTube™ is flat extruded with an EVOH barrier for longer shelf life, and accurate thickness control guarantees smooth processing and dimensional stability. 3D Neopac extrudes and direct prints the solution’s substrate, and mounts the tube’s shoulder and cap – an in-house, turnkey production process lending itself to efficiency.

Tube Design Guide for Recyclability

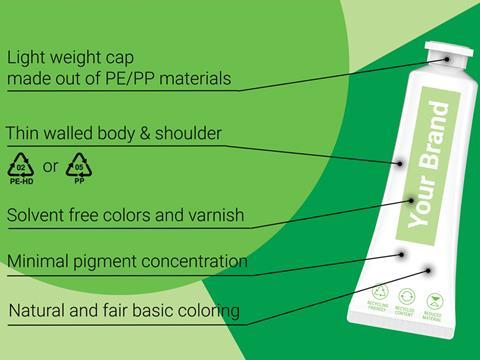

Also at Pharmapack, Neopac will showcase its newly-minted best practices for tube packaging recyclability. The company’s Tube Design Guide for Recyclability is a multi-step tutorial with 'comprehensive consideration' of lighter, more circularity-minded materials, including advice on materials, caps, coloring and decoration.

The EU has announced elevated targets for plastic packaging recyclability, aiming for 50% by 2025 and 55% by 2030. Other geographic areas have introduced similar targets, challenging packaging manufacturers to utilize innovative materials and develop leaner production and supply chain practices. Neopac says its Tube Design Guide for Recyclability is an effort to meet these demands with sound packaging science.