E-commerce has disrupted our shopping habits and the supply chains behind them. Tim Sykes reports on some of the challenges this has thrown up and the packaging innovations and strategies being devised to meet them.

Complex supply chains

The e-commerce supply chain is complex to navigate, and according to DS Smith has over fifty touch points in which a package is handled by machine and human hands – each bringing risks to the playing field.

“As e-commerce sees no sign of waning, more must be done to ensure that the fragility of the supply chain is managed properly,” remarks Isabel Rocher, head of e-commerce solutions at DS Smith. “Problems in the supply chain can cost businesses thousands of pounds, decrease productivity and lead to unhappy customers. DS Smith realises that managing these problems comes through technological innovation. For example, our own DISCS™ technology can effectively test whether packages can survive the bumps and scrapes associated with the average supply chain. This kind of technology is vital given the growing connectivity of customers, who expect high quality packaging that is also sustainable.

Creating right-size packaging

Consumers and brands alike are sensitive to the issue of packaging waste, and in particular excessive packaging. In the early days of e-commerce, one-size-fits-all packaging handling diverse products often fails the efficiency test.

“A key issue in the e-commerce world is the problem of void space, which equates to a valuable waste in resources,” Ms Rocher comments. “Void spaces have a negative impact on the environment around us, producing excess waste and leading to more greenhouse gases being released into the atmosphere – through simply having more vehicles on the road, or using more cargo planes for transport.

"By reducing wasted space, we can limit the amount of packaging used. If all e-retailers make the switch to right-size packaging they will not only see dramatic cuts in their own costs, but customers will save money too. Our own Made2fit technology specifically tackles the e-commerce challenge of void space, as shipping air is a waste of resources. Creating a right size pack lowers costs for e-retailers by reducing both operational and shipping costs: saving storage space, cutting labour costs and order administration, and significantly cutting assembly and packing times.”

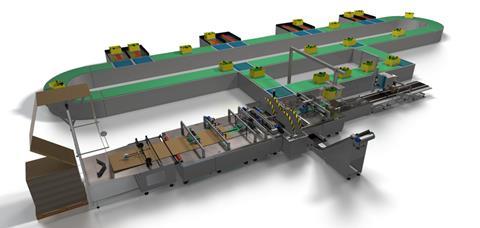

CMC Machinery’s IIOT-powered CartonPack smart case packer represents another approach to space efficiency in e-commerce. At heart of its system is the Vary-Tote, a CMC designed and patented transport tote featuring two inner adjustable guides used to compact the selected items to the minimum possible volume. The Vary-Totes move on a carousel which brings full totes to the machine induct section and, once empty, conveys the totes to the picking area for refilling. The original Vary-Tote design enables an operator to easily and quickly adapt the inner guides to each individual consignment. A 3D Scanner placed in the CMC VaryTote induct area reads the dimensions of the order set by the adjustable guides. Data about the order dimension is sent to the CMC CartonPack, which creates the exact size flat blank for each consignment. The corrugated board required to create the boxes is fed from a dedicated star-shaped device that smoothly unwinds the fanfold and keeps the cardboard flat to avoid creasing. Flats are dynamically scored and cut. A dedicated Pick and Place mounted in the picking area then places the VaryTote above the flat cut on demand. The bottom of the VaryTote automatically slides and items are accurately placed on the preformed blank while the box panels erects and wraps the items. The on-demand box is now formed, closed and sealed with hot melt glue. The entire process is fully controlled by a dedicated PC Carton controller, which guarantees for 100 per cent data integrity and data exchange with client’s WMS.

The significance of this innovation reflects the growth of multi-item orders – now up to 60 per cent of online purchases. Collecting, consolidating and packing items of different size and shape it is a challenge and many retailers still rely on manual packing and use packaging materials inefficiently. CMC Cartonpack right size boxes save 30 per cent of the corrugated board, and eliminate the need for the standard void fillers, and in the process reducing the package volume by up to 60 per cent, thus reducing DIM charges.

Performing in multiple channels

Of course, many products are being purchased in mass volumes through both digital and traditional retail channels. Is e-commerce influencing the packaging used in supermarkets? Are we seeing an emergence of truly multichannel packaging? “This is something we have been looking out for but it doesn’t yet seem to be appearing on a large scale,” Ben Mitchell, research fellow at The Retail Institute, told Packaging Europe.

“One particular area of interest is how packaging features which are designed to appeal to different senses – touch and sound as well as visual elements. How can this work if people are purchasing online? Some products may have less appeal if the packaging loses some of its sensory advantages.”

Similarly, it could also be difficult to convey the functionality of a pack through a photograph on a website. “One approach is for brands change their packs so that images and logos are larger and less detailed so that the product visually is more appealing on a website,” suggests Mr Mitchell. “Also, with there being different requirements for standing out on a shelf compared with being transported direct to consumers without being damaged, it is likely that rather than using a single pack design to perform across multiple channels, there will be packs designed for different types of journey to the customer. It will be interesting to observe how packaging companies and brand owners respond to these questions.”