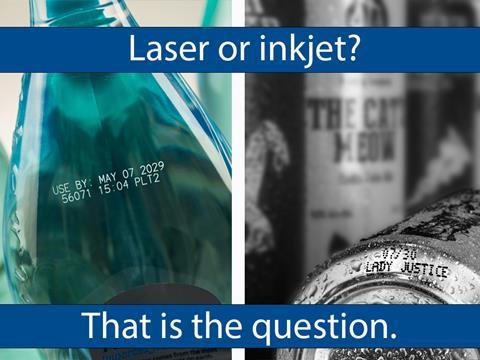

In this edition of the Spotlight, Markem-Imaje lays out the varying applications for laser and continuous inkjet coding technologies – considering the most suitable choice in the contexts of target application, packaging colour, security, sustainability, and more.

Drinks manufacturers are all too aware of the importance of meeting key regulations through the use of safe, legible, long-lasting packaging coding. As with any piece of equipment, there are two costs to bear in mind: the upfront capital investment (CAPEX), and the ongoing expenses incurred when the equipment is operated to code products (OPEX). Two coding technologies address these objectives: continuous inkjet (CIJ), which offers the most flexibility alongside excellent durability, and laser, which offers the most permanent and precise coding available.

While CIJ requires a lower upfront investment compared to laser, there is no right or wrong answer. Making that choice is often more complex and needs to be looked into on an application basis. Let’s look at a couple of examples.

Laser coding: a versatile and effective technology with multiple applications

Laser coding, considered to be an Opex choice, is the go-to option for applications in which marking permanence and environmental impact are critical. With so many differences in laser types and characteristics, the choice of solution is defined by the target application.

In response to the ongoing rise in counterfeiting, beverage companies require a permanent solution that cannot be erased. Despite the initial investment required for a laser printer, the trade-off is worthwhile. While CIJ offers a high level of adhesion and permanence, laser offers a reliable permanent solution for most beverage containers.

Although a typical laser printer is more expensive than a CIJ printer, the initially higher investment can be recovered over time because, apart from air filters, there are no consumables. Options such as Markem-Imaje’s SmartLase C600 and F250 coders reduce operating expenses as they are ink-free, creating permanent codes that do not fade or rub off over time. Laser also has less environmental impact as there are no empty ink cartridges to dispose of, with fewer volatile organic compounds (VOCs) released into the environment during the printing process.

CIJ: a tried, tested, and highly effective technology with broad application

CIJ coding, considered a CAPEX choice, is the strongest option for applications requiring high speeds, flexibility, and excellent code visibility. To meet changing environmental priorities, beverage producers are increasingly considering returnable bottles, cans, and refillable pouches. CIJ delivers the right level of adhesion to ensure drinks products reach the consumer safely while also allowing the marking to be washed off at the recycling stage. Recycling also benefits business profitability as companies can remove the business cost of new containers by using existing ones.

For dark packaging for products such as craft beers, a high-contrast code is best. Laser can be considered an option if used on the label and if the bottle and label size and shape are always the same. On the other hand, if a craft beer producer decides to vary his labels and/or the shape of his container, often the case with different flavours or marketing design, the code will most frequently be applied on the bottle, making CIJ the most viable contrasted technology thanks to the use of pigmented inks.

As mentioned earlier, the initial Capex/Opex approach may be impacted by this type of application as a pigmented CIJ model, capable of managing pigmented inks is required.

These models typically come with a greater CAPEX than a CIJ coder using dye inks because they require a stirring mechanism to prevent the pigment from settling. Something to consider when making that decision. On the other hand, while the market offers several specific pigment models, at a higher price, Markem-Imaje offers several market-first ‘hybrid’ ink circuit models (9750+, 9750 Expert+) that can lessen the overall investment when in need of a mixed dye AND pigment fleet. Something to highlight when a company prefers to streamline their coding activities, costs and resources thanks to the use of one single model.

Unlike laser, CIJ does require consumables, but not all consumables are the same. Opex can be impacted by the choice of ink and the level of consumption. For example, combined with the consumable saving mode (CSM), Markem-Imaje’s MEK-Free ink offering can reduce consumable consumption, VOC emissions, and waste by more than 60%. Yet another variable to consider on a per-application scenario in terms of overall running expenses.

Laser or CIJ: There is no right or wrong answer, they both get the job done professionally

Selecting the right coding solution goes far beyond a simple CAPEX/OPEX approach and is influenced not only by coding speed, print visibility and contrast, and environmental, social, and corporate governance (ESG) considerations but also by application type, speed, branding, and product shape and size. It is only by fully understanding all the options available that manufacturers in the beverage industry can successfully achieve the critical balance between cost and print quality.

As traceability experts, Markem-Imaje can assist beverage producers in selecting the most suitable traceability solution for their specific needs.

This content was sponsored by Markem-Imaje.