A new liquid additive claims to reduce the polymer degradation that takes place during melt processing, 'substantially increasing' physical property retention in regrind as compared with unmodified material.

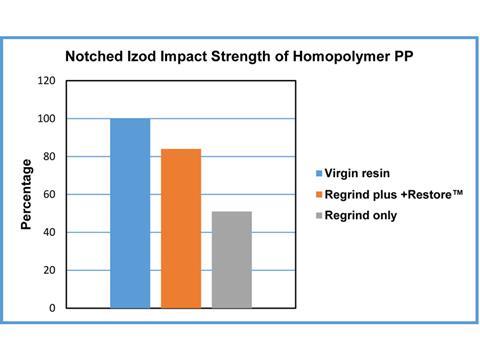

+Restore™ additive from Riverdale Global has exhibited positive results with recycled commodity resins such as polyolefins, according to Jared Arbeter, technical sales manager. For example, he says reground homopolymer polypropylene containing +Restore additive exhibited 65% greater Izod impact strength than unmodified regrind (see chart above). Improvements have also been reported with PP copolymer and HDPE.

The new additive can be used alone or in a blend with Riverdale Global’s liquid colours. Typical usage rates are in the 0.1 to 0.5% range. Processors can use the +Restore additive to enhance the physical properties of virgin materials, although the company says the most dramatic results are exhibited in recycling.

“+Restore enables recyclers to obtain physical properties much closer to those of virgin polymer than with unmodified regrind,” said Mr Arbeter. “This innovation expands end-use possibilities for recycled material, opening new applications in moulded or extruded products, including fibres.”