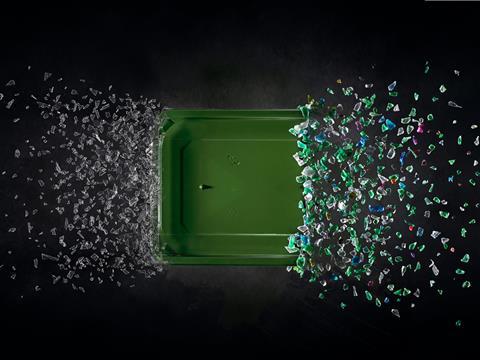

Klöckner Pentaplast (kp) has launched kp Kapture™, a new range of black and coloured trays and rigid films that are produced using carbon-free pigment and made from up to 100% recycled PET making them ‘detectable and fully recyclable’.

The industry – and increasingly the wider public – has long been aware of the issues surrounding the recycling of black plastics. For those who are unaware, the short version is this: black plastics can and should be recycled, but the problem comes down to a question of sorting in the recycling stream.

In the UK alone approximately 12,000 tonnes of plastic packaging containing carbon black pigment are not recycled. Thermoformed trays containing carbon black pigment arrive at the recycling facility along with other mixed recyclable waste and are passed under NIR (Near Infra-Red) sensors to be sorted. Materials containing carbon black pigment become invisible to NIR sensors and go undetected. These products, which should be recycled and reused, are not detected and sorted in the recycling stream for further processing, losing the opportunity to close the loop.

‘Creating a future with less waste’

But that being the case, we may well ask why brand owners would continue to use black or coloured plastics at all. Why not just opt for clear or light blue? Why do we not go further and have an all-out ban?

Well, it’s not as simple as this. For example, black is a useful colour as it can help prevent damage to food products by blocking light from getting in. Black and coloured packaging is also a strong end market for non-clear post-consumer recycled PET as a raw material. And let’s not forget that packaging is a way for brands to communicate with their consumers, so while sustainability is of course the primary concern, there are also questions of aesthetics, differentiation and presentation to bear in mind.

Fortunately, there may be solutions to this challenge that allow us to have the best of both worlds. This is why kp believes kp KaptureTM is an important step forward, as it ‘completely closes the loop on coloured PET, giving retailers the sustainable option to once again showcase their products in the timeless quality of black and coloured premium packaging’.

How is this achieved? According to the company, its black and coloured packaging ranges are detected by today’s recycling sorting technology so they can be turned back into protective packaging again and again, ‘maximising functionality, keeping food fresh and safe, and creating a future with less waste’.

The NIR process detects carbon-free pigment materials and captures them, separating them from other non-detectable carbon black materials using jets of air, diverting the materials into the correct recycling stream. Once the materials are segregated, they are sent away for further processing and cleaning at a plastics recycling facility to create new, food-grade PET flake for manufacturing back into new protective trays or rigid films, closing the loop.

‘Fully tested’

kp confirms its new product range has been fully tested by experts at RECOUP using real-life conditions where kp Kapture™ products were mixed in with other materials while the recycling facility was operating at full capacity. 200 trays were tested and each one was detected and correctly sorted by NIR. Additionally, rigid films produced by kp that are used for form, fill and seal applications and are thermoformed into trays were also successfully detected and sorted by recycling sorting machine providers TOMRA and PELLENC in France.

Stuart Foster, RECOUP CEO says: “RECOUP assisted kp with successful trials to independently demonstrate the detectability of kp Kapture™ coloured trays using existing sorting technology in UK facilities. This ensures the items in the kp Kapture™ product range can be sorted effectively and prepared for onward recycling.”

Adam Barnett, kp’s Food Packaging President says: “This is another milestone towards meeting our commitments set out in our Positive Plastics Pledge to innovate and accelerate our use of recycled materials and close the loop wherever possible. By creating this new product range of black and coloured carbon-free trays and rigid films that are made using up to 100% post-consumer PET we provide our customers and consumers with another recyclable packaging option. It’s also a powerful contribution to our role as signatories to the UK Plastics Pact and our overall efforts to support the work of initiatives such as The EU Circular Economy Plastics Alliance.

“With increasing urgency for action on climate change mitigation, resource conservation and responsible disposal of plastics, kp Kapture™ is the innovation that is needed to help towards reducing carbon emissions and stop valuable material leaking into our land and marine environment. kp Kapture™ can ensure that tens of thousands of tonnes of black plastic makes its way seamlessly through recycling systems, creating a circular economy, and by developing solutions which close the loop, we can reduce the amount of virgin materials used in plastic production.”