Whether described as Industry 4.0, a smart factory concept or expanding the Internet of Things to industrial applications (Industrial Internet of Things = IIoT), all these generally refer to the same thing: the networking and digitalisation of production.

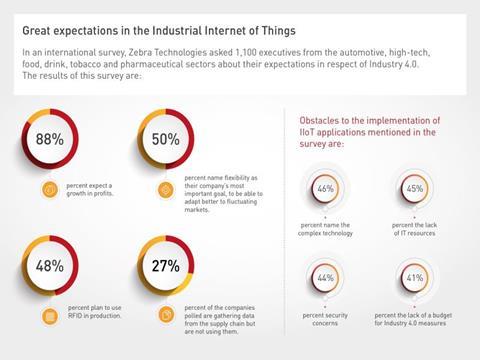

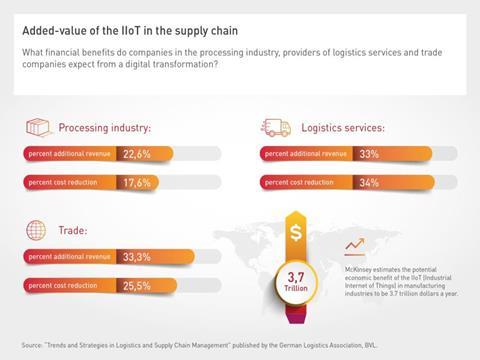

For manufacturers in all sectors, this topic represents a major challenge as well as a unique opportunity. According to a survey by management consultancy McKinsey, the use of IIoT technologies allows companies to reduce their maintenance costs and machine downtimes by up to 50 percent and raise productivity by up to 55 percent. In practice, however, this often doesn’t happen due to a lack of interdisciplinary expertise in selecting the right technologies and integrating them into a comprehensive concept.

For implementing the IoT, technology companies cite a wide range of aspects that need to be tweaked, such as the optimisation of production processes, predictive maintenance, adapting warehousing and occupational safety. In recent years, suppliers from the mechanical engineering, logistics and production equipment segments have increasingly adapted their product ranges to these new challenges. Manufacturers of packaging machines and labelling and marking technology as well as upstream and downstream processes are endeavouring to establish common interface standards such as OPC UA (Open Platform Communications Unified Architecture) so that data exchange within the production chain will function effectively.

From 25 to 27 September 2018, around 1,500 companies from the packaging process chain will showcase their solutions for Industry 4.0 at FachPack. For example, vendors of packaging materials will present smart packaging solutions for intralogistics and shipping that are equipped with RFID technology, for instance, and are therefore integrated into the production IT environment.

By digitalising their processes, manufacturers of packaging machines provide flexible solutions that allow manufacturers to implement the requirements for batch size 1. To allow people to communicate effectively with the technological production environment, companies are developing corresponding HMI interfaces and by using data glasses or digital twins are ensuring new horizons in the field of augmented reality. Regardless of the buzzwords chosen by the exhibitors at FachPack for their respective solutions, digitalisation will always play a prominent role at the European trade fair for packaging, processes and technology.

More info:

www.fachpack.de