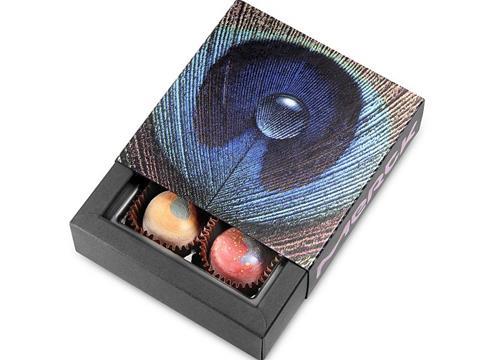

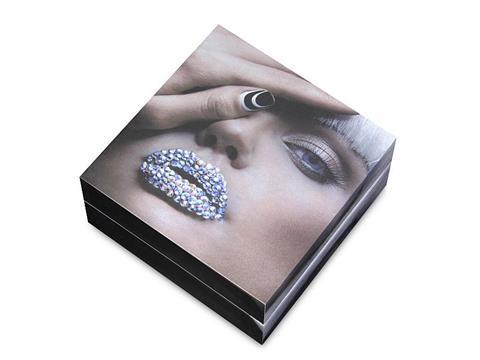

Merck Spectraval TM pearl effect pigments have been launched to open up new realms of printing possibilities.

Supported by the colour range offered by RGB technology, the new concept gives results that literally capture light, making the printed image appear with extraordinary brilliance and depth. Packaging Europe spoke with Peter Clauter, marketing manager, Merck to discover the significance of this printing trend.

RGB vs CYMK?

With traditional CMYK printing, which is based on subtractive colour mixing, each colour that is used reduces the background colour white until eventually you see black.

With RBG, the print world is flipped: colour is additive - SpectravalTM pigments are printed on a black substrate and each layer of colour adds light so that red, green and blue combine together resulting in white. The print enhancements are also flexible- suitable for screen, gravure and flexo printing.

Peter Clauter shares that the RGB technology was first introduced to the market at Drupa 2016: “The first reaction of the marketplace was that this technology is impossible- once they learned the process and results, they wanted to know more.”

He enthuses that for more than one hundred years printing has traditionally used subtractive colour mixing in CMYK on white substrates: “Now with this new technology and pigments, the achievable effects are outstanding, it is extraordinary and unique- and fascinating pearl and metallic effects can be achieved, boosting colour and depth.”

But beside these superlatives, Peter Clauter states that it is not a question of one or the other technology: “Sure you can print only in CMYK or only in RGB. But it is a ‘high art’ of printing to cleverly combine both in one print job. If you think about the modern printing machines this can easily be done, when you have an equipment with eight or more printing units.” With creative designers, limitations disappear.

Point of difference

RGB creates a very different look and feel to the traditional techniques and can be used to add impact that is guaranteed to grab attention. It’s a simple, scientific principle but it’s effective at enhancing prints. According to Merck, RGB printing represents a whole new ball game. It gives new dimensions in effect printing and offers shelf appeal.

Markets in which collaboration has begun on commercial scale with RGB process include: Cosmetic packaging, interior decorations, flexible packaging and magazine covers.

Peter Clauter hints at projects they are currently working on with partners within the decoration paper industry as well as in the packaging fields of folding carton, shrink sleeves and self-adhesive labels.

As long as RGB pre-press is correctly administered to increase the attractiveness of the print product, Peter Clauter concludes, “There are no limits.”

This content was sponsored by Merck.