Sleeve packs made using EconCore’s honeycomb technology have set a new performance standard for the packaging industry, results from a recent compression test show.

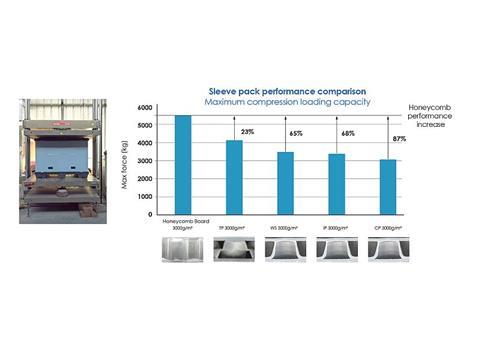

The test, carried out by an independent packaging institute in accordance with ISO 844 guidelines, analysed the maximum compressive loading capacity of reusable sleeve packs made using honeycomb core materials and various other core structures generally referred to as cup-shaped core structures. All packaging products tested had panel weight of 3000 g/m², same dimensions in height, width and depth and were preconditioned for 24 hours.

Results show that the sleeve packs made using EconCore honeycomb technology outperformed all others made with alternative technologies and core structures, ranging from 23% up to 87% higher compression loading capacity. EconCore explains that the honeycomb core better supports the skin of the sleeve pack under load and being better in out of plane compression strength the honeycomb core serves to resist skin wrinkling.

EconCore estimates that over the last three years the share of the market has grown to around 20% in this most demanding of applications. Within Europe the market is strong and looking beyond, particularly in North America, EconCore sees the market gaining momentum and being currently served by sleeve packs made using core materials other than honeycomb. “The opportunity is ripe for a new producer using EconCore honeycomb technology to leap-frog existing producers in the region”, says John Sewell, responsible for Business Development at EconCore.

Honeycomb core based packaging materials enable producers to deliver the highest performing solutions in terms of strength, but also presents the opportunity to reduce weight per piece. “This leads to dramatic bottom-line benefits through reduced material and energy costs”, according to Tomasz Czarnecki EconCore COO, “and potentially at higher output speeds during production”.