Rockwell Automation, a global pioneer in harnessing the potential of the IIOT with ever more sophisticated industrial automation technologies, chose interpack as the stage for its inaugural Best Future Machine competition. Tim Sykes attended the award ceremony to get the winners’ insights into the unfolding capabilities of Industry 4.0 in packaging applications.

interpack 2017 featured a vast array of smart manufacturing solutions, from the special exhibition hosted by VDMA to key product launches by names such as Bosch, Siemens and Schneider Electric. A significant chapter of this story belongs to Rockwell, whose technologies appeared as components of countless innovations across the halls of Messe Düsseldorf. Tonejet’s ground-breaking digital can decorating machine, for instance, relies on Rockwell's iTRAK intelligent track system to accurately transport the cans during the print process and ensure a high-quality finish.

Underscoring the impact of this ecosystem of technologies was the Best Future Machine award. The competition was split into five categories, reflecting key areas in which smart manufacturing has disruptive potential: ease of use, modular machines, smart machines, sustainability, and traceability and product safety.Overall winner was Cama Group, which rated highly in several categories and won in ‘Best Ease of Use’. The award-winning machine was he new IF318 robotised monoblock loading unit.

The solution introduces Cama’s innovative ‘pitch-less’ platform for the robotic forming, loading and closing of cartons from corrugated or paperboard materials. Incorporating many of the features that make Cama’s machines stand out, including cabinet-free technology, ergonomics and friendly use, the machine also leverages iTRAK technology. Meanwhile, Cama developed a Digital Twin for the machine, together with a Pack ML compliant user interface incorporating both condition based maintenance and predictive maintenance capability. According to the jury members, the Cama machine ticked a lot of boxes and showed how an integrated, modular design concept can be incredibly flexible and suit multiple applications.

Sustainability

Winner in the ‘Sustainability’ category was CMC Machinery for its CartonPack solution. Fittingly, the same solution won in the ‘Machinery’ category in Packaging Europe’s Sustainability Awards.

As described in the award citation article, the CMC CartonPack is an essential solution for the e-commerce age. It processes multi-item orders of different sizes and odd shapes, saving 30 per cent corrugated and reducing up to 60 per cent volume in a standard folded carton. Core of the CMC CartonPack is the ‘Vary-Tote’, a CMC-designed-and-patented transport tote system, featuring two inner adjustable guides, which are used to compact the picked items to the minimum possible volume and to define orders dimensions. The Vary Totes move on a carousel, which brings full totes to the machine-induct section and, once empty, conveys the totes to the picking area for refilling.

During the process, a consolidated multiple-item order is initially placed in a Vary Tote and enters the machine. A 3D Scanner placed in the CMC Vary Tote induct area reads the three dimensions of the order set by the adjustable guides. Data is sent to the CMC CartonPack, which creates the exact size flat blank. The necessary corrugated sheet comes from a dedicated star-shaped device that smoothly unwinds the fanfold and keeps the cardboard flat to avoid creasing. Flats are dynamically scored and cut. A dedicated pick & place mounted in the picking area then places the Vary Tote above the flat cut on demand. The bottom of the Vary Tote automatically slides and items are accurately placed on the pre-formed blank, while the box panels erect and wrap the items. The on-demand box is formed, closed and sealed with hot melt glue.

“Our business has a history in designing on-demand packaging solutions for food and confectionery industries, later diversifying into envelope-inserting systems and film-wrapping systems,” Tania Torcolacci, CMC’s marketing manager, told Packaging Europe. “In 2013, combining these different areas of technological expertise – pioneering systems featuring up to 30,000 envelopes/hour – we introduced our new Box on Demand Machines, the CMC CartonWrap and the CMC CartonPack, to dynamically pack single or multiple items fixed together, in perfect size boxes. In the latest three years, we have been heavily investing in R&D activities to engineer innovative solutions for these markets, particularly for e-commerce fulfilment, where our customers are experiencing highly-increasing order volumes (about +30 percent year by year) and multiitem order variability. When it comes to consolidating and packing different size and shape items for shipment it is a hard challenge. CMC worked also to boost the machines’ cycling speed, from 500 boxes/ hour using cardboard from a reel, to 700/1,000 boxes/hour, using fanfold fed corrugated.”

Smart Machines

Meanwhile, Goglio scooped the ‘Smart Machines’ category thanks to its GCap6, displaying its deep knowledge in the coffee sector. This is a filling machine for aluminium capsules that consists of several modules: a loading system for stacked capsule, a double Auger filling system, a checkweigher, a tamping and cleanup device, a cut and seal group of the top lid, a camera for optical control, and an exit pick-and-place device.

Goglio designed the GCap6 automation system carefully selecting solutions and control systems and choosing a particularly user-friendly programming environment, for an easier software development. Furthermore the reduction of installation and start-up training time, the easier identification of problems, testing and validation are some of the advantages that characterize GCap6.

All devices are connected via Ethernet/IP by facilitating communication within the control network. The machine can also be accessed remotely and production data (such as recipes, batch numbers and production quantities) can be directly sent to the machine. The customer can potentially collect an infinite number of parameters and analog/digital data that can be used to implement predictive maintenance.

Modularity

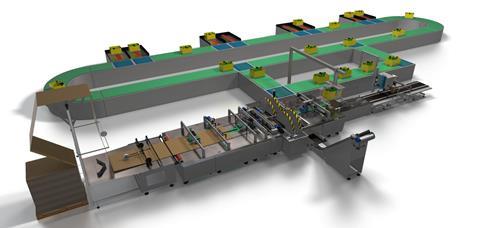

Gebo Cermex took home the prize in the ‘Modular’ category, thanks to its patented CareSelect™ universal and modular shaped-bottle infeed and collating system for robotic or traditional case packers. Once again powered by Rockwell Automation’s iTRAK® technology, CareSelect™ can achieve speeds of up to 400 products per minute depending on package size, shape and weight, easily surpassing traditional ‘endless screw’ collation systems in terms of bottle integrity and protection. The system delivers shaped bottles to the packing machine with precision and care in the correct orientation and pitch, turning each bottle 90°. Even unstable products are smoothly and individually handled via independent movers. To eliminate contact between products, flow is managed without accumulation at the infeed and ‘friction time’ between the bottle and the system - when the bottles come into contact with machine parts - is dramatically reduced (by at least 20 times) compared to traditional infeed systems. It also offers fully automatic changeovers in less than one minute, with no need for mechanical adjustments.

Commenting on the win, Marc Aury, president and MD of Gebo Cermex, said: “We are naturally delighted to receive this global recognition by a jury comprising some of the world’s leading brands. This demonstrates we are rightfully placing our emphasis where it matters most: to bring Smart Factories to life, to create a world of greater choice and unique consumer experience driven by packaging mass customization and product diversity.”

The final category of ‘Traceability and Product Safety’ was awarded to SN Maschinenbau’s FM 200 pouch packaging machine, whose communication capabilities was designed with Industry 4.0 in mind and offers data-capture possibilities for traceability.

Commenting on the judging process, one jury member explained, “This was an incredibly tough competition to judge as some of the machines impressed us across multiple areas. It is obvious to see that innovation is alive in the packaging industry. I am convinced that some of these machines will quickly establish themselves as class leaders.”