As the Sustainability Awards 2020 ceremony draws closer, we speak to another contender - today, it’s the turn of bio-based packaging finalist Fraunhofer Institute for Silicate Research with their bioORMOCER® biodegradable functional barrier coatings. Answering our questions is Dr. Sabine Amberg-Schwab, expert scientist for barrier and multifunctional coatings.

What are the environmental challenges in packaging that your entry addresses, and what impact do you hope it will make?

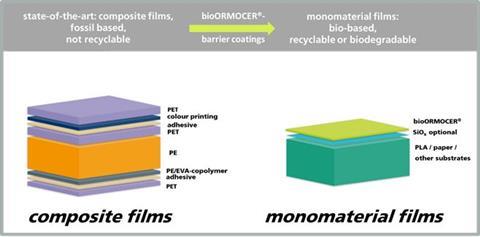

Modern packaging based on plastic or paper is complexly composed of many different materials. Each material performs a specific task in the composite and the thin layers cannot be separated. This impedes recycling, nor can the packaging decompose in nature.

At Fraunhofer ISC, we have developed multifunctional silicate-based barrier coatings (ORMOCER®) We have basically distilled most packaging functions into a single thin layer, thus making multi-layer packaging obsolete. Our coatings (ORMOCER® and bioORMOCER®) are so thin (< 1-3 µm) that the coated packaging materials can be treated as monomaterial packaging. This works for packaging using polymers as well as paper. The properties required for packaging food, cosmetics and pharmaceuticals can be achieved, while monomaterial packaging can easily be recycled several times. For compostable packaging, we have further developed bio-based and compostable bioORMOCER® coatings . We use various bioorganic ingredients from green waste, or chitosan. We do not compete for food crops, but upgrade bio-waste and produce high quality compounds for our coatings.

The basis and model for our new development of the bioORMOCER® is a proven principle from nature: diatoms, or some plants e.g. horsetail, are using silicates to stabilize their cell walls and create very robust structures. We also use silicates and combine them chemically with bioorganic structures, e.g. from green waste, celluloses or chitosan (crabs). As a result, new high-quality compounds (bio-precursors) for the synthesis of coating materials were developed by upgrading bio waste.

Environmental, social and economic opportunities and impacts of our development

Worldwide plastic production rose up to 359 million tons in 2018, estimated increase of 3,5% in 2019, one-third used as single-use-packaging. Less than 10 % were recycled (IEA), as multilayer packaging is only incinerable, not recyclable. The replacement of these materials opens attractive benefits for the environment and economic chances:

- Reduction of CO2 emissions: No incineration of the new packaging material but true recycling (Sustainable Development Goals SDG 15, life on land). ORMOCER® and bioORMOCER® monolayer solutions require less process steps.

- Reduction of energy and material consumption: ORMOCER® and bioORMOCER® based packaging production save energy, material consumption, are more cost-efficient and contribute to sustainable production processes (SDG 12, responsible consumption and production).

- Maximization of independence from fossil resources: bioORMOCER® use no petroleum-based feedstock but fruit residues. We do not have any conflict with food crops, but rather upgrade bio-waste for high quality compounds for the new coatings.

- Implementation of compostable packaging alternatives: an accredited test laboratory confirmed that bioORMOCER®-based packaging material has good composting properties. It may help making communities and environment cleaner (SDG 11, sustainable cities and communities).

- Being part of a growing market: The worldwide bioplastic market expects a growth of 20% to up to 68,577.25 Million USD in 2024 (https://bioplasticsnews.com/2019/08/08/global-bioplastics-market-to-grow-by-20/). With our innovative packaging solutions companies will profit from the growing markets.

In a nutshell: ORMOCER® and bioORMOCER®-based packaging solutions have enormous economic potential, show a way to solve existing challenges regarding pollution, sustainability and social responsibility.

I’d like to ask you about the broader picture beyond your successful entry. ‘Sustainability’ in packaging is multi-dimensional – both in terms of objectives and challenges.

Our modern lifestyle would be unthinkable without packaging. In my opinion, the challenge is that we not only have to reduce packaging materials, make them more environmentally friendly, recyclable or compostable. Rather, we must also educate consumers that packaging is not an annoying waste but a valuable high-performance material. On the one hand, this education could generate more appreciation for packaging and, on the other hand, positively influence the throw-away mentality. Packaging is only improperly disposed of as long as it is considered “garbage”.

In addition, it will be important to promote the full recyclability of packaging and to develop innovative take-back/recycling systems for consumers, which will lead to immediate benefits for both industry and consumers. There is still room for innovative start-ups.

On the industry side, I would like to see more willingness to innovate and implement technology transfer in the short term. We have developed highly potent materials that can be adapted and then simply put into production. The basic development work has already been done. So new solutions could be found quickly. I would simply like to see more openness.

Basically, however, we have to start reflecting our way of living and doing business. We will no longer be able to live out our current lifestyle at the expense of the environment, our resources and at the expense of other countries. A fundamental rethinking is necessary, a completely new way of doing business, which again refers to longevity, reusability and resource conservation. And each individual is called upon to reflect on his or her own way of life and to make changes on a small scale. Many small pieces of the mosaic will form the big whole new picture. Packaging is an important partial aspect.

Could you comment on the most important roadblocks you identify from your position in the value chain, and the kinds of solutions you would like to see addressing them (e.g. areas of technological innovation, collaboration, regulation)?

Our functional coatings can be integrated into state-of-the-art processes to replace current multilayer packaging materials with compostable or recyclable monomaterial solutions. The market potential for these new packaging options is very high. Mass market will reduce production costs to a scale similar to the conventional sector.

As I said above: I would like to see more technology transfer into industry, we offer support and can quickly lead companies to new solutions. Packers and retailers will increasingly reach for these new solutions, because the consumers demand them. Awareness is increasing and costs will not be an argument, because the environmental challenges caused by improper disposal of waste are many times higher. We have to learn to think differently and calculate the total costs of our actions and economic activities. Then many things will look different.