As part of our Sustainability Awards Finalist Interview series we spoke to Wageningen University & Research about its work with Istanbul Technical University to create smart modified atmosphere packaging for fresh produce, nominated in the pre-commercialized Active & Intelligent category.

You’re a finalist in the Sustainability Awards 2023. Congratulations! To start off, could you summarise your entry, in less than 50 words?

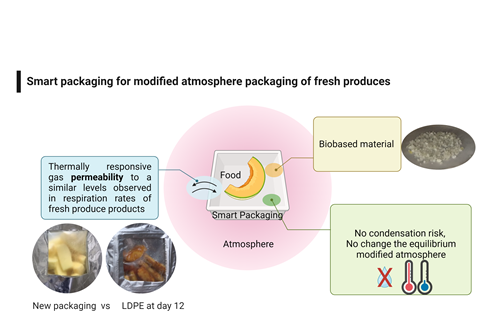

A biobased smart polyurethane film with thermal responsiveness and biodegradability can cut food waste and extend shelf-life. It mimics produce respiration, maintains equilibrium atmosphere, and prevents water vapour condensation without perforation. This innovation has vast commercial potential, reducing postharvest losses and advancing sustainable food packaging.

Why do you think the judges were impressed with your entry? Tell us about what is innovative about your project and/or about its impact on packaging sustainability.

The judges likely found this entry impressive due to its innovative approach in developing a biobased smart polyurethane film for food packaging. The use of renewable sources, absence of solvents or catalysts, and biodegradability showcase a commitment to sustainability. The film’s ability to mimic produce respiration, maintain product quality, and prevent moisture-related spoilage without perforation demonstrates practical and impactful advancements in packaging technology, addressing postharvest losses and contributing to a more sustainable food industry.

When and how do you intend to launch/commercialize this innovation?

Prototypes and tests for regulatory compliance with all necessary regulations and standards related to food packaging performance and safety are ready for this patented innovation. The current need is scaling up production facilities to meet the anticipated demand for the product and developing a comprehensive business strategy outlining goals, pricing, distribution channels, marketing approach, and sales projections.

You’re shortlisted for the pre-commercialized ‘Active and Intelligent’ category. What do you see as the key demands and challenges in relation to smart packaging?

The key demands include product freshness and safety, as consumers seek packaging that can actively monitor and maintain product freshness, extending shelf life and ensuring safety; increasing demand for smart packaging solutions that are environmentally friendly, biodegradable, and utilize renewable materials; and packaging that provides transparent information about the product’s origin, manufacturing process, and supply chain journey.

It also includes enhanced consumer experience through interactive elements such as QR codes or augmented reality, and smart packaging solutions that can streamline inventory management, reduce waste, and optimize restocking processes.

In terms of the key challenges, developing smart packaging at an affordable cost that doesn’t significantly increase the overall product price can be a challenge, as well as incorporating advanced technologies seamlessly into packaging while ensuring they function reliably and durably throughout the product’s lifecycle.

In addition, meeting various regulatory requirements and safety standards associated with the use of smart packaging technologies, especially in the food and pharmaceutical industries; addressing concerns regarding data privacy and security associated with smart packaging that collects and transmits consumer-related information; and educating consumers about the benefits and usage of smart packaging to enhance acceptance and adoption.

Navigating these demands and challenges is crucial to successfully bring pre-commercialized smart packaging innovations to market, ensuring they meet consumer needs, industry standards, and sustainability goals.

What do you think are the main opportunities in this area or what future innovations do you predict in this area?

We are heavily invested in advancing this domain to create innovative materials featuring excellent barriers, biodegradability, and recyclability. Future smart packaging will likely focus on being more sustainable, utilizing biodegradable materials, incorporating recyclable components, and adopting circular economy principles to minimize environmental impact.

There are also opportunities in the integration of IoT technologies into packaging to enable real-time tracking of product freshness, location, and conditions during transit. This could revolutionize supply chain management and reduce waste.

Advanced sensors and indicators integrated into packaging to actively monitor product quality, safety, and freshness could change colour, emit signals, or display information based on the product’s condition. Nanotechnology could be utilized to enhance packaging properties, such as antimicrobial coatings to prolong shelf life and nano-sized sensors for precise monitoring.

Integrating AR (Augmented Reality) into packaging could allow consumers to visualize product details, instructions, or even try products virtually, and implementing blockchain technology to track the entire supply chain could offer them verifiable information about the product’s journey from production to purchase. Also, the integration of advanced authentication technologies like RFID tags, QR codes, or holograms can combat counterfeiting and ensure product authenticity.

These innovations hold the potential to transform the packaging industry, improving consumer experiences, minimizing waste, enhancing sustainability, and ensuring product safety and quality. The future of smart packaging is likely to be a convergence of technology and sustainability to meet the demands of a rapidly evolving market.

The winners of the Sustainability Awards 2023 will be announced at the Sustainable Packaging Summit, which takes place in Amsterdam on 14-15 November. The Summit mobilizes leaders of the FMCG value chain, policymakers, NGOs, recyclers and investors to collaborate, remove barriers and identify opportunities on the road to sustainable transformation.

To learn more or register, visit https://www.packagingsummit.earth/amsterdam2023/.

If you liked this article, you might also enjoy:

The L’Oréal approach to packaging sustainability

What steps is Apple taking to make its packaging more sustainable?

How did Brazil achieve its 100% aluminium can recycling rate – and can it be replicated in the EU?

Experts have their say on the EU’s Packaging and Packaging Waste Directive revisions

No comments yet