First in our Finalist Interview series for the Sustainability Awards is USDA-ARS (the U.S Department of Agriculture’s Agricultural Research Service) with its clamshell with modified humidity. We spoke to research chemist Jinhe Bai PhD about this entry, which has been nominated in the pre-commercialized Active and Intelligent category.

You’re a finalist in the Sustainability Awards 2023. Congratulations! To start off, could you summarise your entry, in less than 50 words?

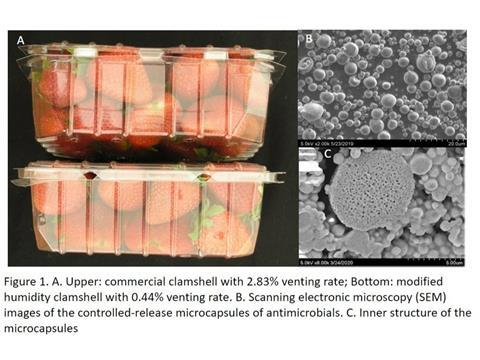

A clamshell with modified humidity, incorporating controlled-release natural antimicrobial agents (for example, thymol or carvacrol) was developed to improve fresh produce safety and quality. The reduced venting increased moisture in the clamshell which minimises water loss in produce and triggers the release of carvacrol and thymol from the carriers.

Why do you think the judges were impressed with your entry? Tell us about what is innovative about your project and/or about its impact on packaging sustainability.

The judges were impressed with my entry because it showcased an innovative approach that has a significant impact on packaging sustainability. One of the key features of the project is the implementation of reduced venting in the clamshell packaging.

This design modification increases the moisture content within the clamshell, thereby minimising water loss in produce. By maintaining an optimal moisture level, the shelf life of the produce is extended, reducing waste.

Furthermore, the reduced venting also plays crucial roles in triggering the release of volatile antimicrobial agents and maintaining sufficient concentration of the volatiles in the package. These natural antimicrobial agents, such as carvacrol and thymol, are released from the natural polymers used in the packaging, such as pectin, dextrin, and alginate, after absorbing moisture.

The controlled release of these antimicrobial agents helps inhibit the growth of bacteria and fungi, enhancing the overall quality and safety of the packaged produce.

Additionally, the clamshell packaging itself can be partially or fully replaced with recyclable and biodegradable materials, specifically pectin-based bioplastic. This choice of materials aligns with sustainability goals by reducing the reliance on non-biodegradable plastics and promoting the use of renewable resources.

Overall, the innovative aspects of this project lie in its holistic approach to packaging sustainability. By utilising natural materials like thymol and carvacrol as antimicrobial agents, employing controlled-release carriers and incorporating biodegradable clamshells, the project minimises waste, extends produce shelf life, and reduces the environmental impact of packaging materials. These factors collectively impressed the judges and demonstrated a strong commitment to advancing sustainable packaging practices.

When and how do you intend to launch/commercialize this innovation?

The launch of this innovative humidity packaging solution is planned to take place in the first quarter of 2024. The primary objective is to address the concerns raised by blueberry farmers regarding the significant loss and waste of their high-quality berries during the postharvest process.

To initiate the launch, extensive collaboration with industry stakeholders will be key. Fruit growers, packaging manufacturers, and distributors will be engaged to establish partnerships and gather valuable insights. By understanding their specific needs and challenges, we can refine the packaging solution to effectively address the issues related to postharvest handling, transportation, and marketing.

Feasibility studies will be conducted to ensure the scalability and efficiency of the packaging solution. This will involve testing the technology in different environments and scenarios to validate its effectiveness in minimising water loss and combating microbial contamination. The results of these studies will provide valuable data to further optimise the packaging design and production processes.

Scaled-up production will be a crucial step in bringing this innovation to market. Collaborating with packaging manufacturers, we will ensure the availability of the humidity packaging solution in sufficient quantities to meet the demand. The manufacturing process will prioritise sustainability, aiming to use eco-friendly materials and efficient production techniques.

Strategic partnerships will be established to facilitate the distribution of the packaging solution. Engaging with distributors and retailers will help ensure that the innovative packaging reaches the market efficiently and is accessible to blueberry growers and other fruit producers. Marketing efforts will be focused on highlighting the benefits of the packaging solution, such as reducing fruit waste and enhancing packaging sustainability.

By actively involving industry stakeholders, conducting feasibility studies, scaling up production, and establishing strategic partnerships for distribution, the aim is to launch this innovative humidity packaging solution swiftly and effectively. The ultimate goal is to make a tangible impact in reducing fruit waste and improving packaging sustainability in the blueberry and small fruit industry.

You’re shortlisted for the pre-commercialized ‘Active and Intelligent’ category. What do you see as the key demands and challenges in relation to smart packaging?

Being shortlisted for the pre-commercialized ‘active and intelligent’ category indicates recognition of the potential of smart packaging. In this context, key demands and challenges related to smart packaging include:

Integration of advanced technologies: smart packaging requires the integration of various technologies such as sensors, RFID tags, and communication systems. The key sensors include real-time humidity detectors, antimicrobial volatile detector, deterioration detector and more. Meeting the demand for seamless integration and compatibility among these technologies is crucial.

Data collection and analysis: smart packaging generates a vast amount of data related to product quality, safety, and logistics. Effectively collecting, managing, and analysing this data is essential for obtaining valuable insights and optimising processes.

Connectivity and communication: smart packaging relies on connectivity to transmit and receive data. Ensuring robust and reliable communication networks, especially in diverse supply chain environments, poses a challenge that needs to be addressed.

Cost-effectiveness: developing cost-effective smart packaging solutions is vital for widespread adoption. Balancing the costs associated with technology integration, production, and implementation is a challenge that must be overcome.

Regulatory compliance and consumer acceptance: smart packaging may involve compliance with regulations regarding food safety, data privacy, and environmental sustainability. Additionally, consumer acceptance and trust in the benefits and security of smart packaging are essential for successful adoption.

Overcoming these demands and challenges requires collaboration among stakeholders including packaging experts, technology providers, regulatory bodies, and end-users. Continuous research, development, and testing will be crucial to refine smart packaging solutions and ensure their viability and positive impact on various industries.

What do you think are the main opportunities in this area or what future innovations do you predict in this area?

In the realm of smart packaging, several exciting opportunities and future innovations are anticipated:

Enhanced traceability and supply chain optimisation: smart packaging can enable real-time tracking of products throughout the supply chain, providing accurate information on origin, handling conditions, and shelf life. This technology has the potential to improve traceability, reduce waste, and optimise logistics and inventory management.

Intelligent freshness indicators: future innovations may include more advanced freshness indicators that utilise sensors and data analysis to provide consumers with real-time information about the quality and safety of packaged products. This would enable consumers to make informed decisions and reduce food waste.

Interactive packaging: packaging could become interactive and engage consumers through augmented reality (AR) or near-field communication (NFC) technologies. This could provide additional product information, recipes, personalised offers or even gamified experiences, enhancing consumer engagement and brand loyalty.

Active preservation and shelf-life extension: further advancements in active packaging, such as incorporating antimicrobial agents, oxygen absorbers, or moisture regulators, can extend the shelf life of perishable goods. This would contribute to reducing food waste and enhancing product quality and safety.

Sustainability-focused innovations: the future of smart packaging lies in integrating sustainable materials, recyclability, and biodegradability. Innovations in eco-friendly sensors, energy-efficient communication systems, and renewable energy sources can further enhance the sustainability of smart packaging solutions.

Personalised packaging experiences: smart packaging has the potential to deliver personalised experiences tailored to individual consumers’ preferences and needs. This could involve customisation options, nutritional recommendations, or allergen alerts based on user profiles and data analysis.

Integration of blockchain technology: blockchain can provide secure and transparent information sharing within the supply chain, ensuring data integrity and traceability. Its integration with smart packaging can enhance trust, authenticity, and compliance across the entire product journey.

These opportunities and future innovations have the potential to transform industries, improve consumer experiences, reduce waste, and contribute to a more sustainable and efficient global supply chain. Continued research, technological advancements, and collaboration among industry stakeholders will drive these developments forward.

The winners of the Sustainability Awards 2023 will be announced at the Sustainable Packaging Summit, which takes place in Amsterdam on 14-15 November. The Summit mobilizes leaders of the FMCG value chain, policymakers, NGOs, recyclers and investors to collaborate, remove barriers and identify opportunities on the road to sustainable transformation.

To learn more or register, visit https://www.packagingsummit.earth/amsterdam2023/.

No comments yet