ExxonMobil will introduce Rethink Recycle with Vistamaxx™ performance polymers – a solution that the company says allows increased recycled content utilization for high-value applications ― at its K2019 pavilion (FG10.1).

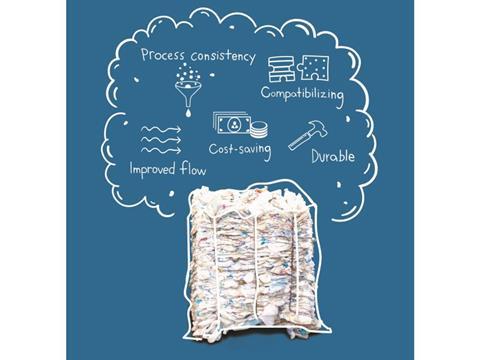

Due to its molecular design, Vistamaxx polymers act like a compatibilizer between polyethylene (PE) and polypropylene (PP) in recycled content streams, enabling it to improve the properties of recycled content containing products.

“One of the main barriers to using recycled material is the need for costly and time-consuming separation of incompatible plastics,” said Beth Galvin, Solution Performance Plastics, Global Marketing Manager, ExxonMobil. “By allowing incompatible PE and PP plastics to mix in the melt, Vistamaxx performance polymers can reduce the need for separation. This provides manufacturers with the opportunity to produce higher-quality products, increase utilization of recycled content, and access new alternate lower-cost raw material sources.”

Using Vistamaxx™ performance polymers increases process consistency by enabling manufacturers to overcome variability in melt flow characteristics. Vistamaxx can also tailor the melt flow of recycled content streams to meet the process needs of the end-use application. Introducing recycled content into products often reduces the toughness and tear resistance of products, but the addition of small amounts of Vistamaxx performance polymers enhances the toughness and tear resistance of end products.