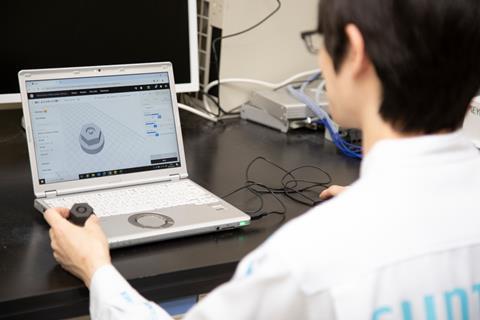

How does Suntory, a global beverage industry giant, keep its machinery running smoothly across a number of its key facilities? In partnership with Markforged, Suntory harnessed the power of innovative 3D printing technology, enabling them to produce custom parts on demand – cutting lead times by 83% and reducing part costs by 70%.

As a result of reduced downtime and simplified manufacturing flows, Suntory says that it has been able to streamline its manufacturing processes and better manage the demands of its extensive production network.

Fill out the form below to learn more about this project.

No comments yet