In April, Tetra Pak unveiled an ‘industry-first’ paper-based cap for its carton packages, made from 87% renewable content. To learn more about this innovative solution, we spoke with Aldo Fontana, Global Product Manager at Tetra Pak.

To start with, please could you introduce this development to our readers who may have missed the initial announcement? What, in your view, makes this especially exciting?

We’re breaking new ground in the packaging world, Tetra Pak is developing a paper-based cap, now being tested on beverage cartons in Spain. So, we’re the first in the carton packaging industry to trial a paper-based cap in a commercial consumer test.

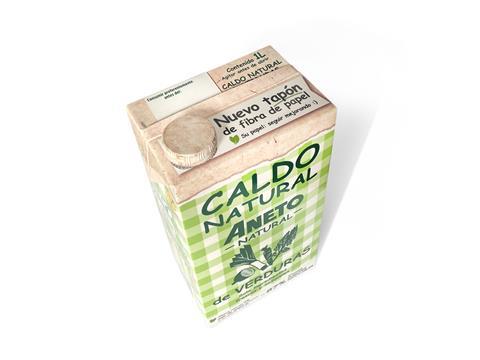

Replacing the plastic cap with a paper-based alternative is another step to increase the share of paper content in each package. In this trial, the paper content of Aneto’s vegetable broth packaged in a Tetra Brik® Aseptic 1000 Mid carton increases by three percentage points, now representing approximately 73% of the total package share by weight.

Together with plant-based polymers used in the packaging material coatings and the neck of the opening, the overall share of renewable content in actual material weight in the package reaches 87%. That means consumers get a high share of renewable materials in their packaging, making it easier to make more sustainable choices without compromising on convenience.

Increasing paper content also helps reduce the carbon footprint and is key to optimising recycling. Increasing the renewable share in every carton helps us move towards a circular economy in which products can be recycled and made into new products. The shift towards paperisation signals transformation for the industry and Tetra Pak is excited to be leading the way.

Please could you tell us more about the cap itself? Exactly what is it made from, and how much of the cap is made from each material?

The paper-based cap is an opening device for carton packages made primarily from paper rather than polymers. This consumer test involves a two-step screw opening device: the screw cap is formed from moulded paper fibres while the neck, pull-ring and inside plug of the cap are made from plant-based polymers derived from sugarcane, making it a fully renewable cap.

How can the cap be recycled, and have you conducted any LCAs to determine its carbon impact versus conventional alternatives?

Beverage cartons can be recycled where collection and recycling infrastructure exist at scale. In this consumer test currently taking place in Spain, beverage cartons featuring a paper-based cap are sorted and collected for recycling in the existing local recycling stream as per other beverage cartons. Increased paper content makes our packaging even more appealing to recyclers because of the increased yield of recoverable paper fibres.

Beverage cartons have a lower carbon footprint than other packaging options for food, such as glass, plastic, or metal, as demonstrated by Life Cycle Assessments (LCAs) and product carbon footprint calculations in many markets. As the paper-based cap is in its test phase, we don’t have LCAs determining carbon impact just yet, but at Tetra Pak, we are excited about the way the paper-based cap is set to revolutionise the closures category.

Once we reach the industrialisation phase of this product development, we look forward to further quantifying this data.

What were the main technical barriers that had to be overcome during the R&D process? And how does the paper cap perform from a functionality point-of-view when compared with plastic alternatives?

Developing a paper-based cap is an ambitious undertaking that requires carefully balancing package integrity, production line compatibility, and consumer functionality. It isn’t as simple as swapping materials, especially as paper has traditionally been used for packaging rather than closures. Instead, using this material for a cap means we need to rethink raw material sourcing, supply chain adaptation, manufacturing processes, and consumer interaction.

The cap needs to be able to handle moisture, temperature shifts, and transportation stress while maintaining product quality. As with every new product, we conduct rigorous testing to issue a food contact certificate that allows a product to go to market. The paper-based cap meets the same performance standards as plastic caps; it is easy to open, resealable and durable.

I’d like to learn more about how the collaboration with Aneto will work in practice. What are the objectives of the testing process, and what does success look like?

We are collaborating with long-time customer Aneto, from Spain. Aneto has consistently pushed boundaries to align packaging choices and values, so it made perfect sense for the company to put the industry-first cap on the shelf for a commercial consumer test in Spain. In 2021, for example, Aneto introduced sugarcane-based polymers in both caps and packaging material coatings, increasing the share of renewable materials in their products.

Aneto’s vegetable broth was chosen for the consumer test as it enjoys steady year-round demand, making it an ideal choice for a controlled production run. The pilot batch appeared on shelves in selected stores in Spain. We aim to assess the technology and consumer acceptance of the concept, which will determine possible future applications.

What would it take to scale a solution like this so that it becomes a viable alternative to conventional plastic caps?

Our goal is to maximise paper content in our solutions, while making the transition smooth for food and beverage producers and consumers. We intend to develop a paper-based cap that fits into the conventional process where the cap is applied downstream by a cap applicator, so it can be adopted at scale using existing equipment with only minor adjustments to production settings.

In this consumer test, we are also checking consumer experience and acceptance. We want to use these consumer feedback and insights to further develop and scale the solution.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet