BOPET Films Europe and Searious Business outline the practical challenges of recycling household flexible packaging, encourage manufacturers to switch to mono PET in line with the Vita Nova recycling initiative, and invite our readers to visit BOPET’s members at interpack and attend its upcoming webinar in this edition of the Spotlight.

Despite the numerous industry pledges, the clock is ticking towards 2025, and the household flexible packaging industry still has a problem with circularity. A flawed assumption that the success story of the mechanical recycling of unprinted large format post-industrial PE films can be replicated in the much more complex area of household flexible packaging has led to design guidelines being rushed out, which not only do not enhance recyclability but also incur significant economic and environmental costs.

Throughout 2023, BOPET Films Europe aims to demonstrate the valuable role that PET films play in approximately 25% of all household flexible packaging structures, providing data to articulate the environmental cost of designing out PET from mixed plastic laminates and the environmental benefit of moving to mono PET flexibles where appropriate.

Unfortunately, mechanical recycling is not a viable option at industry scale for household flexible packaging due to the wide range of substrates, complex mix of inks and adhesives and residual food waste, and the lack of financially viable end markets for the resulting low-value recyclate. It is clear that a different approach is required if a truly circular economy for household flexible packaging is to be achieved.

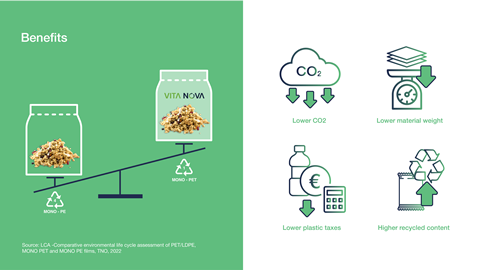

Working in partnership with Searious Business, the aim of the Vita Nova initiative is to demonstrate the incredible potential that all PET structures have to deliver; a significant decrease in carbon footprint and an increase in circularity. Due to the combination of the inherent properties of PET and the best-in-class high plastic-to-plastic yield recycling processes, mono PET structures offer the only viable option for a truly circular model for household flexible packaging. Switching to mono PET structures where possible will significantly decrease the overall use of plastic and the associated carbon footprint, whilst delivering a sustainable source of food contact-approved recyclate - the gold standard of a circular economy for flexible packaging.

For those applications where polyolefin-rich structures are the right material choice, we will continue to demonstrate the financial and environmental cost of designing out PET from mixed plastic laminates. Also, through our work with companies commercialising advanced recycling technologies, we will demonstrate that low levels of PET do not have a detrimental effect on the yield of useful products.

Time is short. A change in approach is required if the household flexible packaging industry is going to deliver on its commitments to increase product circularity whilst optimising design and performance to minimise carbon emissions throughout the supply chain and product life cycle.

“It’s time to dare to think differently. We need visionary brand owners and retailers to join us in making household flexible packaging fit for the future.” – Rosemarie Wuite, Searious Business

BOPET Films Europe members will be pleased to welcome you at interpack 2023 to discuss in more detail the positive role that BOPET films play in the flexible packaging industry, and don’t miss our webinar on the 6th June where we will dive into more detail on the environmental benefits of mono PET flexibles.

This content was sponsored by BOPET Films Europe.