AVT, a world leader in print inspection, print process control, and quality assurance solutions, will showcase systems for automation and efficiency supporting Industry 4.0 production environments at LabelExpo Europe, September 25-28 in Brussels. Visitors to AVT’s Stand 9C05 will discover how its solutions tie into print automation and “smart factory” production excellence.

By connecting AVT to pre-production tools – such as management information systems (MIS) or Esko’s Automation Engine – printers can define and control cross-plant quality standards, monitor production floor key performance indicators (KPIs), uncover potential improvements, aggregate data and benchmark against defined targets. Another featured solution is AVT’s SpectraLab II, an inline, automatic spectral measurement system compliant with X-Rite’s discerning, ISO-compliant XRGA metrology standard, certifying the system's ability to optimise color measurement across multivendor networks, among other allowances.

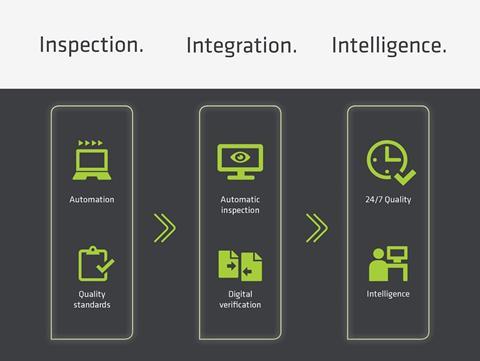

AVT also will be among industry leaders participating in LabelExpo's Automation Arena, where two start-to-finish lines will demonstrate – via compatible partner solutions – complete digital and conventional printing lifecycles from job creation through pre-press, printing, finishing and invoicing. AVT will showcase additional Industry 4.0 solutions at its stand, including demos of the company’s forthcoming iCenter Platform, a next-generation cloud-based solution that empowers printers to manage and control quality and production standards for facilities around the world - ensuring global consistency. Through iCenter, printers can set cross-site quality standards, auto-analyse PDF files for inspection, and utilise business intelligence from the production floor with seamless connectivity to MIS and prepress solutions for optimised, automated workflows.

Inline Automatic Colour Measurement Solutions with X-Rite Certification

AVT also will exhibit its SpectraLab II, a new generation of inline, automatic spectral measurement for nearly any application, including transparent flexible, paper, cartons, etc. Offering compact design, advanced colour workflow management and improved inline-to-offline measurement correlation, SpectraLab II meets colour specialist X-Rite's strict, ISO-compliant XRGA Standard for the graphic arts industry. Based on the proven SpectraLab, with more than 30 packaging and label customers worldwide, and AVT’s Clarios, which is used on over 800 in-line colour systems throughout the world, AVT’s colour management prowess offers real-time spectral measurements like LAB, DeltaE and dot gain.

Leader in Digital Inspection & Press Control

For the first time at LabelExpo Europe, AVT will demonstrate Helios D (digital), a high-end 100% automatic inspection system specifically designed to address digital printing challenges such as missing nozzles, ink drips and colour uniformity – all in real time. Another key tool to reducing waste, enhancing production and making process monitoring truly comprehensive, Helios S Turbo is installed on HP Indigo 8000 label press. A similarly streamlining AVT solution, Apollo 20K, will be showcased on an HP Indigo 20000 packaging press.

AVT also recently introduced Jet-IQ, a closed loop solution that allows digital printers to gain a competitive advantage through enhanced print quality at high speeds, reduced press down time, and full reporting capabilities. At LabelExpo Europe, visitors can see the solution in action on a Mark Andy digital press, as well as a Gallus Labelfire.

According to Jaron Lotan, President & CEO of AVT: "Now that AVT is part of the Danaher family of companies, we have even more opportunities to work with strategic partners to collaborate on interconnected, 'linked' solutions that automate workflow while providing insight into production behaviours. As a solutions provider who has always seen advanced metrics and quality control as key components for comprehensive inspection, this leaves AVT well-positioned for the Industry 4.0 revolution."

More info: