In this edition of the Spotlight, PerkinElmer give us a useful overview of the analytical methodologies and recommended instrumentation to detect and prevent the problem of NIAS in products.

Analytical testing of Food Contact Materials (FCM) for Non-Intentionally Added Substances (NIAS) is important to ensure both safety and compliance. NIAS are substances that can transfer into food from FCM but are not intentionally added during the manufacturing process. As the use of recycled materials steadily increases, the risk rises and the need for analytical testing to identify and quantify NIAS and assess their potential health risks is of growing importance.

NIAS include impurities, reaction products and degradation products that arise from the manufacturing processes of plastic materials or non-plastic food contact articles. Typical recycling-related NIAS are mineral oil hydrocarbons (MOHs), bisphenols, phthalates, and photoinitiators in recycled paper or board as well as flavour compounds, oligomers, and additives in recycled plastics.

Regulation (EU) 10/2011 states that potential health risks should be assessed by the manufacturer in accordance with risk assessment principles. Because there are so many potential unknown NIAS which could migrate into food and it is difficult to completely understand and control processes, manufacturers need reliable testing regimes to ensure their products reach the shelves.

The specific migration limit permitted depends on the substance’s estimated harmfulness, ranging from 10 µg/kg to 60 mg/kg.

Gas Chromatography (GC) and Liquid Chromatography (LC) are some of the most reliable technologies to separate, detect and identify organic compounds. Whereas inorganic elemental analyses require atomic spectroscopy techniques such as Inductively Coupled Plasma Mass Spectrometry (ICP-MS) or Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES).

Headspace sampling combined with GC and FID-detection [flame ionization detector] is a robust method to determine volatile compounds such as benzene, acetaldehyde and limonene out of PET.

Instead of using a GC-FID setup, a gas chromatography mass spectrometry system with headspace sampling will lead to more detailed insights and could help to better identify other hazardous or unwanted volatile components in virgin or recycled plastics.

Bisphenol A (BPA) is another NIAS example, occurring as a consequence of environmental contamination or through the recycling stream. HPLC [High-Performance Liquid Chromatography] with fluorescence detection is well suited to rapidly identify and quantify BPA. Further sensitivity can be achieved by using triple quadrupole mass spectrometry.

Some packaging may require elemental analysis if metal-based lids, seals or other components are incorporated into the package, or to detect in-production contamination from machinery or waterborne sources. Both ICP-OES and ICP-MS can identify toxic metals – which is especially important for recycled materials. ICP methods are used to study inorganic additives such as pigments or fillers. For example, by analyzing potential additive metallic impurity interactions with plastics.

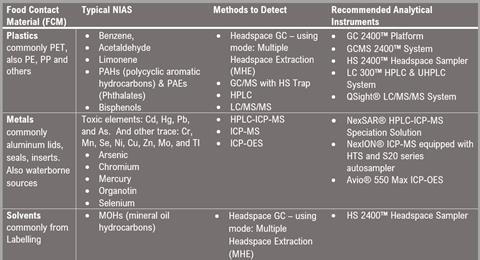

COMMON EXAMPLES: FCM, NIAS, ANALYSES, INSTRUMENTS

Download the Food Packaging Compendium for a range of useful application notes with lab methodologies.

Listen to scientist Miles Snow as he explains the advantages of using pressure balanced headspace sampling technology to separate and identify potentially toxic volatile organic compounds:

For more information about PerkinElmer laboratory solutions for packaging, visit: www.perkinelmer.com/packaging-analysis.

This content was sponsored by PerkinElmer.