In this edition of the Spotlight, Checkpoint explains the role of RFID technology in the food sector, particularly when it comes to food safety and supply chain management.

As consumer demand for transparency and high-quality food continues to rise, the food and beverage industry is undergoing a significant transformation. One of the key drivers of this change is the adoption of RFID technology, which enhances various aspects of food safety, supply chain tracking, and inventory management.

RFID tags for food safety

Ensuring food safety is paramount in today’s market. RFID tags for food safety are crucial tools that help food companies meet stringent regulations like the FSMA 204 in the United States, which mandates detailed record keeping for high-risk foods starting in January 2026. These regulations aim to quickly identify and remove contaminated foods, thereby reducing foodborne illnesses and deaths. Europe and other regions are also advancing their traceability and quality assurance standards.

RFID tags enable detailed tracking of food products from their origin through processing and distribution, right up to the point of sale. This precise tracking helps in quickly removing expired or contaminated items, thus enhancing food safety and ensuring that consumers receive fresh, high-quality products.

Revolutionizing the food sector with RFID technology

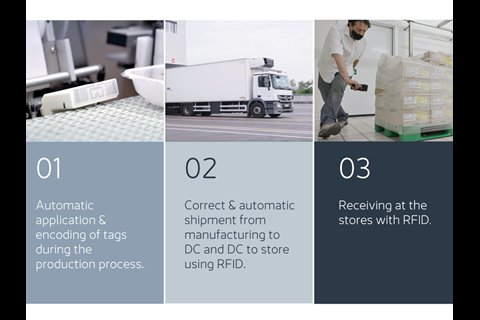

RFID technology in the food sector is transforming the way food products are managed. By implementing RFID tags, companies can achieve significant improvements in traceability, inventory management, and logistics. This technology allows for the seamless tracking of food items from production to the consumer’s plate, fostering greater trust and transparency.

The logistical benefits of RFID technology are substantial. It eliminates the need for manual scans, reduces delivery times, and boosts operational efficiency. For consumers, the access to detailed product information builds confidence and strengthens their relationship with food brands.

Enhancing food supply chain tracking

Food supply chain tracking is essential for maintaining the quality and safety of food products. RFID solutions provide precise monitoring of each step in the supply chain, from farm to table. This comprehensive tracking ensures that any issues, such as contamination or spoilage, can be quickly identified and addressed.

Innovative companies like Checkpoint are leading the way with RFID technology. The Leveche tag, part of the RFreshID™ food waste solution, significantly reduces food waste by 50%. Certified for microwave use by EECC and for indirect food contact by ISEGA, these tags ensure safety and reliability. They also resist interference from liquids or moisture, which is common in fresh foods, ensuring optimal RFID performance.

Streamlining food inventory management with RFID

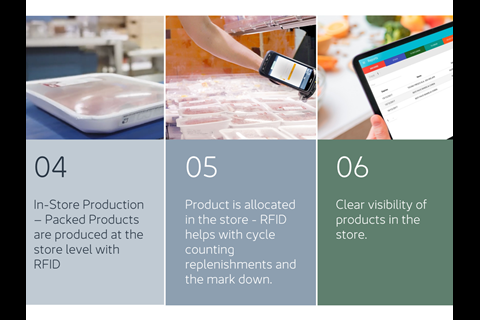

Effective food inventory management RFID systems are crucial for modern food businesses. RFID tags automate inventory tracking, reducing the need for manual record-keeping and minimizing human error. This leads to better inventory control, less food waste, and more efficient operations.

In retail settings, RFID technology accelerates product reception and enables real-time inventory management, ensuring that shelves are always stocked with fresh products. This efficiency translates to lower operational costs and a superior shopping experience for consumers.

Embracing RFID for a safer, more efficient food industry

Adopting RFID technology in the food supply chain offers numerous benefits, from enhanced traceability and inventory management to improved logistics and reduced food waste. By embracing these innovative solutions, companies not only comply with stringent regulations but also build consumer trust and promote sustainable practices.

Join the revolution in food safety and quality with RFID tags. Enhance your supply chain, improve operational efficiency, and foster transparency to meet the demands of today’s informed consumers.

This content was sponsored by Checkpoint.