Manufacturers striving to meet their environmental goals need greater awareness of the critical role of static energy management and contamination control in advancing sustainability, Meech International advises.

As industries worldwide accelerate the shift toward sustainable, single-material packaging, driven by the new European Packaging and Packaging Waste Regulation (PPWR), manufacturers are facing an unexpected challenge—heightened static buildup and contamination risks in the new processes and materials being developed to meet the directives’ requirements.

New technologies, such as Material Directional Orientation (MDO) optimize raw materials like polyethylene (PE) by enhancing properties such as stiffness, transparency, and heat resistance. This enables lightweighting, which reduces material usage and lowers costs associated with transport and logistics.

However, the four key processes in this technology, heating, stretching, annealing and cooling, each generate significant static charges and consequent side effects, which, if not managed or directed properly, can threaten the sustainability of the manufacturing process.

“We are seeing much higher levels of static build-up with changing new materials and processes where 8 – 10 rollers are involved. The changes in material chemistry are also likely to be a contributory factor to the significant increases in contamination being reported in production, ” Ian Atkinson, sales director at Meech, explained.

“MDO film technology is emerging as a game-changer in the pursuit of a circular economy and the ability to meet stringent targets for recyclability and waste reduction, but the awareness and appreciation of the importance of static and contamination control have not kept pace with development in material technologies,” he said.

Static has been an issue in manufacturing since industrial processes began and the costs in terms of safety, production efficiency and quality are well documented. For example, a recent analysis carried out for a customer with a single ‘traditional’ 1,200mm wide press demonstrated that stoppages and loss of quality due to static build up caused a £13,000 monthly loss in raw materials of ink and paper.

Despite this, the role of static in disrupting manufacturing and web processing is often forgotten, or only the most basic solutions are implemented. The amount of static and scale of loss in new material technology processing lines has the potential to be many times greater due to the increased complexity and operating speeds of the new technology.

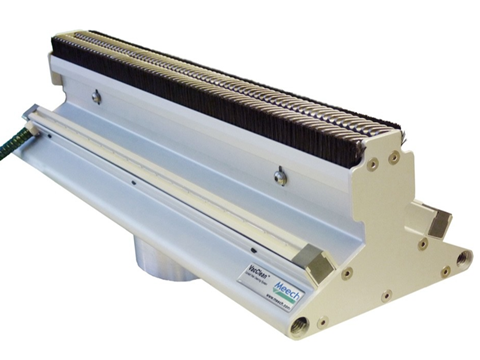

“Our research has identified that in new blown film technologies, specific, more specialized static management and web cleaning equipment is required at different key stages of the process to address problems that have arisen and are unique to the new processes and materials,” Atkinson said.

One of these new problems is the build-up of powder and flakes on the material and machinery rollers thought to be derived from additives such as slip agents in the new materials, combined with the process technology. Machines are having to be stopped for long periods to clean the equipment. Where this stoppage doesn’t take place, print quality is being affected and rejects due to poor quality are increasing.

“Greater awareness of static and contamination removal early in the adoption of MDO lines will enable faster and more successful production outputs by ensuring contamination is not baked in to the materials from the start of this innovative new processes,” Atkinson concluded.

If you liked this story, you might also enjoy:

Reuse vs. single use – which is better for the environment?

Sustainable Innovation Report 2025: Current trends and future priorities

What can the world learn from South Korea’s world-leading performance in plastics circularity?

No comments yet