While progress has been made across the board in recycling PET, the challenge of white bottles had remained. Can a white opaque masterbatch be used in PET monolayer bottles, including recycling rates of up to 100%, without impacting production and/or end product property like light barrier?

Sukano and Sidelset out to technically prove that Sukano-designed white opaque masterbatch formulations can indeed be used in PET monolayer bottles, and still be processed at the same machine throughput, using Sidel’s most recent generation of blow-moulders, EvoBLOW™, with no impact on color, properties, functionality or production rates.

Sukano’s technical expert team started by formulating monolayer PET white bottles masterbatch and submitting them for recycling using the European PET Bottle Platform (EPBP) protocol. The melt viscosity, pressure and stability, was determined to be well processable. In addition, the high quality melt filterability indicated its purity and consistency. The melt also showed very stable color, with the end material remaining white at all levels, highly similar to the initial virgin PET white bottles - also at 100 % RPET. Finally, the IV were also reported stable, with a level of 0.65 at all stages of recycled PET. The Solid State Polymerization (SSP) process evidenced similar rate as for the virgin PET, with an IV level of 0.7/0.8.

As one of the key factors, no agglomerations were found. Thanks to the formulation and ingredients used by Sukano technical experts, including selected raw material surface treatments that are compatible and stable during recycling.

“The results are not a surprise but actually a satisfaction to have it scientifically proved and confirmed,” said Michael Kirch, Global Head of R&D at Sukano. “We are convinced that the design guidelines for recyclability of white opaque PET bottles can be enhanced to reflect the needed technical requirements that enable bottle-to-bottle light barrier white opaque PET to come to life.”

When design formulation expertise successfully meets top-edge blowing technology Sidel, a leading provider of equipment and services solutions for packaging food, beverage, home and personal care products in PET, can, glass and other materials, used the recycled material in its high speed PET blowing machine, to produce 25%, 50% and 100% light barrier white opaque R-PET bottles. Light barrier was adjusted by adding a Sukano-designed white PET masterbatch formulation, except in the 100% R-PET content bottle. In this case, the difference in terms of color shade versus the original virgin bottle was barely noticeable, and the integrity of the light barrier was confirmed for extreme conditions, such as less than 0.1% light transmission at 550nm wavelength.

“We saw no measurable difference in processing conditions or blowing output while processing the 100% recycled white PET material from Sukano-designed white masterbatches, even under most challenging conditions,” said Naima Boutroy, Global Packaging Expert from Sidel. “While a few adjustments to the process may be needed to optimize the overall result, our joint achievement and proof of concept enables us to raise the bar, with great bottle mechanical and physical performances.”It is now clear that a routine can be established to create an official outlet for opaque PET bottles, and the impact on the environment could be relevant. One of the greatest achievements of our collaboration is the demonstration that a light barrier white opaque PET bottle can indeed be up to 100% bottle-to-bottle recycled, going back to the same application or being upcycled and used for new added-value outlets."

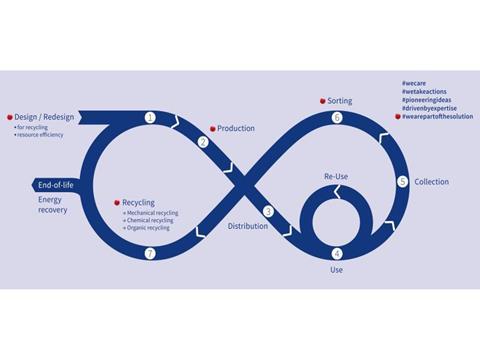

“Every local market is a key player to ensure that the circular economy does indeed join up. We are happy to announce we have taken another step forward by confirming the recyclability of light barrier white opaque PET bottles – and most importantly, offering an alternative end of life that goes back into its original application.” Says Alessandra Funcia, Head of Sales & Marketing at Sukano.