As the European Union’s Packaging and Packaging Waste Regulation (PPWR) comes into focus, the fibre-based packaging value chain faces a critical moment. The question at hand: how can fibre-based paper, board, and moulded fibre packaging rise to the challenge of replacing plastic packaging?

In the latest edition of the Spotlight, we hear from Kemira about the role of chemistry in enabling fibre-based packaging materials, in light of developments around the European Union’s PPWR and Single Use Plastics Directive (SUPD).

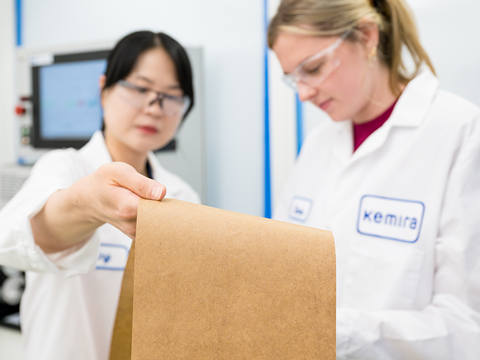

“Chemistry plays a pivotal role in this shift,” says Sami Puttonen, senior manager of Global Sizing and Surface Business Development at Kemira. “It is the invisible enabler that allows fibre-based packaging materials to meet the demanding requirements of applications like food packaging.”

Sami has been closely monitoring the regulatory landscape in Europe, most recently particularly the developments surrounding the Single Use Plastics Directive (SUPD) and the PPWR. “Fibre-based packaging is crucial for a circular, sustainable society. We support all efforts that drive the transition and focus on developing solutions that help our customers and the broader packaging value chain meet their sustainability goals.”

Currently, all eyes in the packaging industry are on the final approval of the PPWR and the completion of its accompanying delegated and implementing acts. Additionally, the update to the SUPD is expected in 2027.

“These regulations will significantly impact the future development of the packaging industry,” Sami notes. “Rather than imposing categorical bans, the focus should be on assessing overall environmental impacts and supporting new innovations. It’s also essential to have incentives for developing adequate recycling infrastructure, which is crucial to ensure that packages designed to be recycled are, in fact, recycled within the EU. Without it, valuable raw materials like wood fibre could go to waste.”

Recyclability: the foundation of sustainable packaging

Paper and board packaging are recyclable by nature – and in Europe, also recycled: today, paper and board boast significantly higher recycling rates compared to other packaging materials.

“Recycling must also remain the primary end-of-life option for any paper, board or moulded fibre packaging. This ensures high material efficiency; that the valuable fibre raw materials are recovered and reused effectively,” Sami says.

As a global leader in sustainable chemical solutions, Kemira is dedicated to developing renewable chemistry innovations for fibre-based packaging in everyday consumer use, such as packaging for food and beverage, cosmetics, and electronics. One key area is the development of renewable barrier coating solutions for oil, grease, and moisture resistance in paper, board, and molded fibre packaging.

“We’re actively collaborating with multiple partners, exploring various technologies and piloting alternatives to commonly used PE (polyethylene) films and harmful PFAS (per- and polyfluoroalkyl substances) with our customers. Compostability and biodegradability are crucial attributes, but those need to be achieved in a way that does not impact the recyclability of the packaging.”

End-to-end chemistry expertise for sustainable packaging

Whenever conventional solutions are replaced with new alternatives, the challenge is to ensure that functionality and safety of the packaging is not compromised, while also placing significant emphasis on maintaining the production and cost efficiency of the packaging material producer.

Developing new, high-performing barrier coated packaging materials requires careful consideration of the entire process. The right choice of barrier chemistry is just the beginning.

“To fully optimize and sustainably implement new technologies, it’s essential to look beyond barriers and the coating application and focus on the end-to-end process. With our extensive experience in papermaking, from pulping to coating, we can provide comprehensive support that helps both the packaging material producers and the brand owners to achieve their goals.”

“The future of packaging lies in partnerships,” says Sami. With the right expertise, the packaging value chain can achieve all the benefits chemistry can provide.

This content was sponsored by Kemira.