As part of our Innovation Spotlight series, Mondi explains how it is ‘leading the charge’ in circular and sustainable packaging solutions with its FunctionalBarrier Paper Ultimate - a paper-based solution said to deliver high barrier performance comparable to selected multi-material laminates in defined applications.

FunctionalBarrier Paper Ultimate brings ultra-high protection to applications that historically depended on complex, unrecyclable laminates. With an oxygen transmission rate (OTR) below 0.5 cm³/m²·d and water vapour transmission rate (WVTR) below 0.5 g/m²·d, the material delivers top-tier barrier performance while being paper-based.

Designed with both brand performance and sustainability in mind, this innovation is part of Mondi’s re/cycle portfolio, packaging solutions that meet the company’s stringent Path to Circularity Scorecard and are recyclable according to the Cepi Recyclability Laboratory Test Method (Version 1 – January 2025) and technically recyclable in mills with conventional processes per the 4evergreen Recycling Evaluation Protocol.

Targeting high barrier food applications

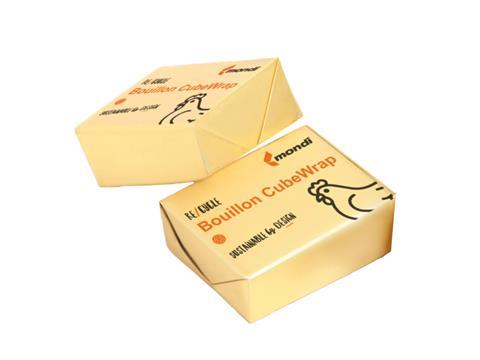

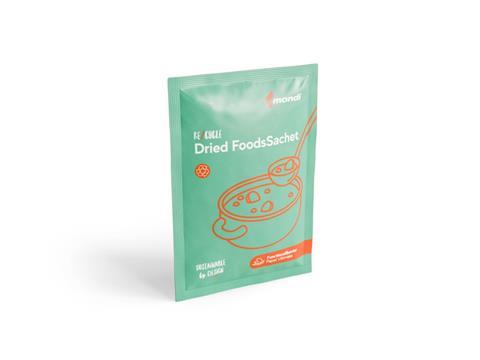

FunctionalBarrier Paper Ultimate is engineered to protect sensitive food and beverage products, making it ideal for high-barrier applications such as instant coffee sticks, bouillon cube wraps, muesli and cereal bars, dried seasonings and tea sachets. The combination of shelf-life assurance and ease of recycling gives brands an edge in balancing convenience with sustainability.

“FunctionalBarrier Paper Ultimate is the result of customer-driven innovation,” says Dirk Gabriel, COO of Consumer Flexibles at Mondi. “With this solution, we are helping brands to move away from multi-material packaging that is unrecyclable, without compromising on performance. This is another concrete step towards our MAP2030 sustainability commitments. Not only replacing aluminium and plastic structures with paper but also delivering a substantially lower cradle-to-grave carbon footprint, according to internal Mondi product impact assessments.*”

* The product impact assessment compares conventional high-barrier structures (PAP 60/Alu 6.35/PE 30 and PET 12 / Alu 7 / LDPE 80) with Mondi paper-based FunctionalBarrier Paper Ultimate (90 gsm and 60 gsm) (end-of-life EU27).

Seamless integration for packagers

Another advantage is operational compatibility. FunctionalBarrier Paper Ultimate is designed for horizontal and vertical form-fill-seal (FFS) machines. Depending on the application and type of final packaging, converters and brands can integrate the material with minimal disruption to existing processes.

By broadening the capabilities of paper packaging without sacrificing barrier protection, Mondi is effectively challenging the assumption that sustainability must come with trade-offs. Instead, it’s proving that with the right technology, paper can do more.

The future, wrapped in paper

In the customer push for recyclable packaging, Mondi’s FunctionalBarrier Paper Ultimate offers a compelling model for the future. It’s not just an incremental upgrade; it’s a leap toward sustainable packaging that performs at the highest level.

As Gabriel adds: “87% of Mondi’s packaging portfolio is already reusable, recyclable, or compostable. FunctionalBarrier Paper Ultimate brings us even closer and gives our customers a powerful new tool to meet their own circularity goals.”

This content was sponsored by Mondi.