A research team at the College of Natural Resources and Environment in Virginia Tech University, USA claim to have proved that biodegradable bioplastics can form durable, protective films on paper using a spray-coating technique, improving strength and barrier properties.

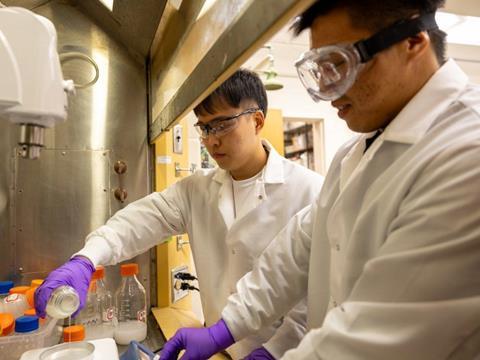

Led by Young-Teck Kim, associate professor of sustainable biomaterials and affiliated faculty member of the Macromolecules Innovation Institute, the proof-of-concept study apparently demonstrates how spray-coated layers of bioplastics can improve the strength and barrier properties of paper packaging while maintaining its compostability.

Conducted in collaboration with Zhiwu Wang and Haibo Huang in the College of Agriculture and Life Sciences as well as Su Jung Hong of Kyung Hee University and other partners, the research was published in Progress in Organic Coatings and supported by the U.S. Department of Agriculture’s National Institute of Food and Agriculture.

Kim’s team used a spray-coating method that replaces the extrusion process typically used to apply bioplastics such as polylactic acid (PLA) and polyhydroxyalkanoate (PHA). By integrating the spray step into paper manufacturing, the method could reduce material waste and energy use while improving coating consistency.

“Our spray process achieves even coverage down to five microns thick and can be incorporated into the paper mill process with only one additional process,” Kim said.

The research team found that blending the two bioplastics provided complementary benefits. PLA formed a dense surface layer that sealed the paper’s pores, while PHA penetrated the fibrous structure to enhance internal strength. A 50/50 blend achieved the most balanced results, improving tensile strength and oxygen resistance.

The resulting coated papers are said to have shown stronger mechanical properties, improved water resistance and enhanced thermal stability while remaining biodegradable. Compared with uncoated paper, the spray-coated samples were ‘up to twice as strong’ and had ‘dramatically lower’ oxygen transmission rates.

While the initial study used organic solvents to test the feasibility of the spray process, Kim said the next step for the research team is to develop a water-based, solvent-free version that will further increase environmental safety and industrial viability.

Earlier this year the BIOPROCESS project was announced, run by AIMPLAS, Potato Bioplastics, and Gaviplas and aiming to bolster the mechanical and barrier properties of flexible bioplastic packaging in the food, cosmetics, personal hygiene, detergent, and cleaning sectors. The project seeks to improve the protective qualities and extend the shelf life of biodegradable and/or compostable bioplastics, assisting in the phase-out of fossil-based, non-biodegradable plastics.

More recently, paper and board barrier solutions provider Subeco and biomaterials provider Paques unveiled a joint development plan for ‘fully biodegradable, circular’ PHA-based barrier coatings. The companies aim to deliver coatings that make packaging fully biodegradable and independent of fossil resources.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet