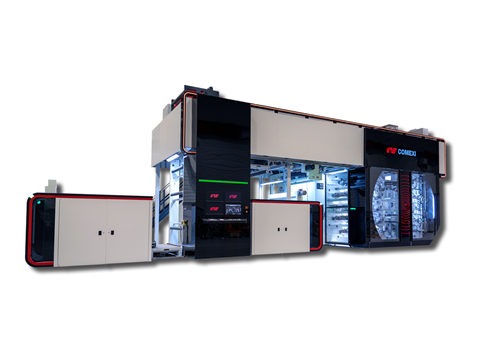

Coveris aims to improve flexo print efficiencies and energy consumption with its investment in the Comexi press, due to be on show at drupa 2024 in Düsseldorf, Germany.

The new press is said to deliver high print quality and high-speed efficiencies alongside minimized and customized energy consumption per job. It is expected to be operational by August at Coveris’ flagship facility in Louth.

Printing with 10 colours at up to 600 m/min, the 1.7m wide-web press uses GeniusTech automated intelligence to optimize changeovers, impressions, and registration. Coveris anticipates the press will deliver capacity increases in rapid-downstream print for fresh food and beverage films, supporting the site’s continued growth in recyclable MonoFlex and recycled ReGen extruded films.

The company hopes the press will support strategic growth plans in the produce films sector, allowing the business to better support seasonality and market volatility through more dynamic print technologies.

Commenting on the investment, Paul Barber, managing director of Coveris’ Louth plant, said: “We’re very excited to announce this investment and the opportunity to showcase it at the world’s leading print event alongside Comexi. Offering unrivalled quality and speed alongside minimized waste, energy and process, this really does represent the future of print and we look forward to sharing the technology both with our customers and at drupa.”

The Comexi press will be on show at the Comexi Group Industries, S.A.U. stand at drupa, in Hall 10 / C19, 28th May – 7th June 2024.

HP will be spotlighting its latest print innovations at drupa, alongside a keynote on its vision for the future of the print industry. The company will display advanced production and printing solutions designed to automate commercial print and packaging production lines alongside its design capabilities, including its latest innovations within the Large Format Business.

Fiery will also attend drupa 2024 with its range of printing technologies for packaging, direct-to-film, and industrial applications, among others, as well as new DFE solutions and workflow software for digital print. Fiery’s specialty production printers utilize AI, cloud, and automation technologies in an effort to achieve high-quality colour, precision, efficiency, and profitability.

If you liked this story, you might also enjoy:

How are the top brands progressing on packaging sustainability?

The ultimate guide to global plastic sustainability regulation

No comments yet