In our latest Innovation Spotlight, Ivana Thiesson and Iwan Tresch, Marketing Manager and CEO respectively of plastics processing company Fischer Söhne AG talk about their company’s cutting-edge production, development, and design capabilities.

Customized plastic solutions for the life science industry

Fischer Söhne AG was established in 1923. Today, it is a successful, highly productive Swiss company. We are an integral solution provider for every stage of the development process, including industrialization and production. Traditionally focusing on packaging, we deliver finished products from a broad range of plastic materials to fulfill the customers’ needs.

Certification

We stand for quality and conduct our quality system according to ISO 9001, ISO 13485 and BRC (food) standards. We put the needs of our customers first, and take care of all production process steps including inspection, cleaning, assembling, packaging and, last but not least, the logistics of all goods.

Clean room class GMP C

We manufacture high-grade products and complete assembled devices out of several raw materials. This includes the range from commodity plastics to high-value-engineering thermoplastics (i.e. PSU). Our environment in that field meets the requirements of a GPM C class (ISO 7) clean room production.

The medical and pharma industry is a continuously growing area. To keep up with this constant growth we have already expanded the clean room with additional injection moulding machines. We are one of the few suppliers of pharmaceutical packaging on the market that has multiple injection moulding machines with a clamping force up to 500 tonnes in a clean room environment.

Your advantage

Thanks to our specific technical and regulatory knowledge, we develop tailormade products. Starting from the initial concept phase up to the final product, we provide a competent and integral service at every stage of the product life cycle.

The product range serves a wide variety of applications with emphasis on secondary packaging systems for the pharmaceutical, medical and health care markets. Our customer profiles cover local as well as international companies.

Ready-to-use containers for sterile injectables: “tub” and “nest”

In the future, the production of sterile injectables will be more efficient, highly flexible, less complex and quicker to adapt to rapidly changing market requirements and patient needs. To support the pharma industry, Fischer Söhne AG has produced successful ready-to-use packaging solutions for almost two decades.

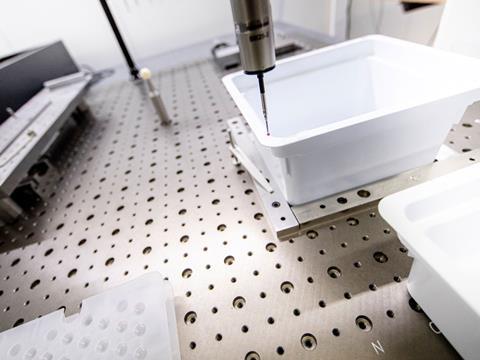

The so-called “nests” and “tubs” are produced in a GPM C class (ISO 7) clean room. The parts are moulded with single-cavity tools or with a stack mould configuration as multi-cavity tools. To reduce contamination, the parts are handled with robot systems. Furthermore, the packaging of the “nests” and “tubs” is highly automated, including the labelling process. As we are able to run the production 24/7, we can, therefore, produce small as well as very large quantities.

The ready-to-use tub and nest enables our customers to use the parts on their existing machines. Additionally, it is also a safe transportation configuration, preventing glass-to-glass contact and reducing defects like scratches, breakage, and particles. Subsequently, manufacturers can reduce the number of filling lines needed to produce various drugs. This reduces the TCO (Total-Cost-of-Ownership).

In-house development

As the Swiss market-leader for extrusion blow moulding and with excellent injection moulding knowledge, Fischer Söhne AG can offer the following development and project phases:

- Design proposal

- Conceptual preliminary study

- Development / Prototypes

- Industrialization / Qualification and Validation

- Production

- Continuous improvement

When carrying out a project, we are obligated to ensure that your products entirely fulfill the requirements and that the time to market is as short as possible. In the development phase, we make sure that we identify the most secure, efficient and effective manufacturing process for your product.

This content was sponsored by Fischer Söhne AG.