What are today’s realities for CPG companies along the supply chain and how can contract packaging services help them approach these in the most effective way? Victoria Hattersley spoke to Steve Sena, Vice-President of Business Development at packaging services provider Truvant, to find out.

CPG companies face many complex challenges when it comes to bringing their products to consumers. These range from the practical (e.g. how supply chain complexity can impact efficiency) to the environmental (e.g. designing packages that promote circularity while avoiding waste) and more besides.

This is where the contract packaging, or co-packing, service comes in. Co-packing companies can fulfil many services, from something as simple as adding bar codes or labels to handling the entire packaging value chain, from product and packaging development, production to inventory management, filling and distribution. Truvant, formed in 2020, through bringing together multiple copackers with a wide scope of services, provides CPG companies with a full range of end-to-end packaging solutions including supply chain consultation, packaging design (including eco-design), logistics, e-commerce and more, in addition to producing and/or packaging the actual product.Here, we are going to look in a more granular way at just four of the biggest challenges Truvant hears about from its clients and some of the ways they can address these.

1. GROWING SUPPLY CHAIN COMPLEXITY

Steve Sena tells us this is probably the most commonproblem he hears about from customers. Getting a product safely to the storeshelf involves an incredibly complex web of packaging processes starting rightfrom the package design, material procurement and moving through production andpacking (involving a combination of automation and manual labour) throughlogistics and finally to the end consumer. All of this has to be delivered insometimes very stringent time-frames, particularly given the growing demandproducers are facing for just-in-time deliveries and ever-greater productchoice.

“Complexity is the dominant challenge our clients face,” says Steve Sena. “Stock-keeping unit (SKU) proliferation has infected nearly every CPG as they seek consumerism a multitude of retail channels and markets (each requiring a different package).Also contributing to SKU proliferation is the variety offered in flavours, colours, sizes, features, etc. the brands need to grow sales. This complexity has hampered the ability to accurately forecast demand for manufacturing of each SKU several months out, thus creating a scenario where stock outs are common or slow-moving SKUs are taking up valuable warehousing space.”

Added to this, the growing taste for customization adds even more SKUs for brands to manage (Steve Sena highlights bundles, giftsets, variety packs and in-store displays, and this is just the start).

“Despite these factors, customization is a high return marketing investment and adds more sales, so it’s necessary in today’s retail environment. Customization typically involves much less volume to build, so leveraging automation is difficult to do as bespoke operations are by nature highly manual manipulations. “This is an entirely different approach that has to run alongside the automated, high-volume production lines.

For Truvant, building a supply chain that is efficient despite all these complexities means creating the right balance between all these factors to enable ‘the right product, in the right format, in the right place, at the right time to delight the consumer’. Increased automation is of course an inevitability; Steve highlights that collaborative robots are getting smarter and more adaptable. In future we can expect to see greater interconnectivity between robotic processes, AI tools and deep learning software in order to build more predictive supply models and Truvant is opening an innovation lab to help its customers and operations manage this paradigm shift.

These increasingly globalized supply chains also add logistics complications. This being the case, Steve believes it is imperative that the industry finds a way to de-couple the manufacturing of goods process and the packaging process – the latter of which often happens at the end of the manufacturing production lines. This, he says, ‘kills agility and flexibility’ since it is based upon forecasted demand several months prior.

“From that point forward, the supply chain is like moving popcorn around the world amplifying the storage space and transportation lanes. We want to put packaging closer to a real demand signal, which turnaround time is mere days instead of months. Isn’t it better to move kernels around the world and pop it where it’s needed (and customized to the consumer’s liking?).”

2. THE GROWTH OF E-COMMERCE

While the Covid-19 crisis has certainly accelerated the e-commerce boom as more and more people have turned to home deliveries for both essential and non-essential items, this is really only the continuation of an ongoing trend. How can brand owners navigate the increasingly important world of e-commerce, and what role does the packaging supply chain play here in facilitating this?

“E-commerce is a whole new channel that changes the supply chain from case/pallet handling and transport to individual item handling and transport,” says Steve. “This impacts the packaging requirements to ensure the product is protected before reaching the consumer.”

Inpart this comes down to more innovative package design (wine bottles that fit through the letterbox are just one example); in part it comes down, as we have mentioned above, to more sophisticated automated packaging processes on the factory floor itself to unlock labour efficiency and meet demand for speedier deliveries.

There are many examples of how aco-packing company such as Truvant can help companies optimize their packaging and supply chains for e-commerce. Steve highlights the potential of ships-in-own-container(SIOC) as “an efficient method of delivery whereby the packaging is sturdy enough to survive parcel shipping without another layer of outside protection(e.g. corrugate shipper).” The result is a more practical, lower cost and, most importantly, environmentally sustainable solution.

3. MEETING SUSTAINABILITY OBLIGATIONS

We know that every CPG company has to play their role helping the world meet its carbon reduction targets and move towards a circular economy. The question is how? There are so many factors to be considered, from materials used, to package design, labelling, production methods, delivery and so on, ad infinitum.

“There are two stories to be told here,” says Steve Sena. “One is ‘cost’, which is dominant in the US, and the other is ’compliance’, which is dominant in the EU. Sustainable alternatives have frequently not reached a scale yet that reduce packaging material costs. However, other sustainability efforts can both lower costs and benefit the environment. An example of this might be reducing the overall cube of a package – which then correlates to smaller cases, smaller warehouses, more cases/pallets on a truck, less trucks on the road. We also promote the use of cellulose-based materials, which are inherently sustainable and biodegradable.”

He does, however, stress that generally speaking Truvant takes an agnostic approach when it comes to materials; it all comes down to the specific requirements of the client and their products. There is not – and will never be – an optimally sustainable solution that fits every single use case.

There has been increased interesting the value of reusable packaging and we have seen some innovative solutions from brand owners over the past year or so. However, uptake is still not as high as many would hope and the Covid-19 crisis – which has placed an understandable emphasis on hygiene and safety – has further slowed down the ’reuse revolution’. What does Steve think the long-term outlook is for reusables?

“If the consumer is willing to pay more, then anything is possible. However, reusables is a difficult challenge because of the reverse supply chain involved. We think a more promising alternative is re-fillable solutions, where consumers are provided replenishment consumer goods in sustainable, even spartan packaging to re-fill their bottles, cans, dispensers, jugs they already have at home. We also feelthat shipping density is important, or higher active ingredient concentrations. There are many ways to improve how products are delivered to stores or direct to consumers.”

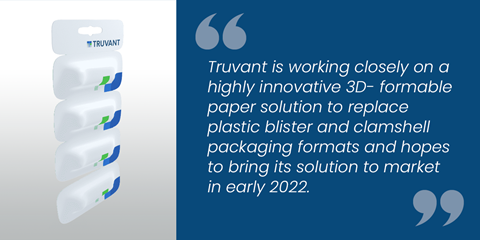

One relatively new innovation Steve is keen to highlight as a ‘game-changer’ is 3D-formable paper. Made from 100%primary fibres, this can be bent and manipulated to allow for a much wider range of creative paper packaging options than previously available. It enables, he says, customizable 3D designs on packaging and – importantly for packagers – can be used on existing thermoforming equipment to produce trays for food packaging, saving them additional investment. Truvant is working closely on a highly innovative 3D-formable paper solution to replace plastic blister and clamshell packaging formats and hopes to bring its solution to market in early 2022.

4. THE ‘RISK’ OF DIGITAL TRANSFORMATION

And this last point brings us onto another major consideration for the packaging value chain. While we might say that digital transformation is something that everyone in the industry must embrace, there are still many – manufacturers, for example – that are reluctant to make the necessary investments. Admittedly, the initial outlay of such a total paradigm-shift can be large: even though there are increasing numbers of novel packaging materials that can run on existing packaging lines, there are inevitably going to be costs involved in full digitalization of the entire supply chain. For Steve Sena, the impetus for this transformation should come from the CPG companies themselves.

“Transformational change has to be a top-downpriority in CPG companies. There are a lot of legacy costs, real estate,personnel, equipment already in place to make classic supply chains work.Changing that to a leaner, agile, sustainable offering is perceived to bewasteful and risky, unless you have experience and know what you’re doing(Truvant does!). Governments can restrict plastic content or truckdriver hours,but only ‘creating a TRUe competitive adVANTage’ in the marketplace willpromote change for visionary companies – then everyone else has to playcatch-up.”

Indeed, we might think that the biggest risk for companies along the packaging value chain long-term actually comes from not making those investments.

FINDING THE RIGHT CO-PACKER

If companies are considering using a co-packing service to address some or all of these challenges, it’s worth taking time to find the right one. There are so many to choose from today, but not all of them will provide the same kind – or indeed quality – of service. So how can CPG companies choose the right solution provider for them?

“If their project is a one-time, limited scope project requiring manual labour, there are thousands of small, regional contract packagers that would love to do the work,” says Steve. “Making gift set, or building a club pallet are good examples. If you are looking for a partner to be a critical element of your supply chain with sustained volumes and unique equipment requirements, not many firms can do this well or at scale. Especially if you want this to happen across multiple geographies such as the Americas, EMEA, and APAC all delivering the same solution at the same level of quality and service.”

And finally, what questions should brand owners be askingprospective service providers to ensure they are the right fit, or that theycan truly deliver on the claims they are making?

“Don’t wow me with slick PowerPoints and nice diagrams….let me see your operations!” says Steve. “Let me talk to your references! I would also encourage brand owners not to simply seek out a reduction in costs because every single one of them want to sell more product –so look at your problem through that lens. Who can help you sell more products to more people in more places?”

This premium feature brings a completely new way for you to interact with our audience through a combination of collaborative editorial and premium promotion. An article written together between you and Packaging Europe’s content team, The Wider View will have a dedicated widget across all web pages & eNewsletter, and will link to a stunning, long-format web page put together by our design team featuring your graphics and branding. Carrying no other advertising, and pushing the limits of ordinary web communications, this is the ultimate digital content package.

No comments yet