We're talking with Highcon in this edition of our interviews with the 2020 Sustainability Awards finalists, who tell us about their technology that they say can minimize waste, reduce carbon footprint, and improve e-commerce packaging.

Congratulations on being selected by the international judging panel as a Sustainability Awards 2020 finalist! Could you please introduce your successful entry and tell us what’s innovative about it?

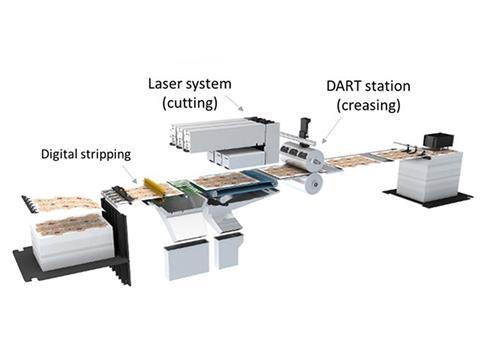

Highcon was the first company to introduce digital technology to the world of packaging converting which had not changed in around 150 years. Our digital cutting and creasing solutions combine laser cutting with digitally-driven physical creases, produced in one pass.

The introduction of these two technologies into one machine completely eliminates the need for a die-cutting tool (which has been used up until now) consisting of wood, metal, rubber components; all of which not only take up huge amounts of room, but also need to be stored, usually for years.

Furthermore, an additional module built into the Highcon machines allows for automatic stripping, removing the need for an additional stripping tool. The innovation stems from the implementation of a range of multi-disciplinary inventions in one machine.

What are the environmental challenges in packaging that your entry addresses, and what impact do you hope it will make?

The key environmental challenges in packaging that we see are mainly in the area of waste, reduction in packaging material consumption, and carbon footprint.

In terms of waste, the technology includes on-demand production, no MOQs, no write-offs, and supply chain improvements.

Our technology also reduces carbon footprints by eliminating the transport of dies between the die-maker and requiring the use of less material to keep the same strength

In addition to these factors, Highcon has an advantage in the e-commerce space, where far more protective packaging is required for transport.

I’d like to ask you about the broader picture beyond your successful entry. ‘Sustainability’ in packaging is multi-dimensional – both in terms of objectives and challenges. Could you comment on the most important roadblocks you identify from your position in the value chain, and the kinds of solutions you would like to see addressing them (e.g. areas of technological innovation, collaboration, regulation)?

We believe the biggest challenge is that of inertia. The way things have always been done is not necessarily the way they should continue to be done.

Particularly with COVID-19, we believe there will be a swing towards a preference for local production, less commoditization driven by international price considerations.

This, combined with rocketing e-commerce sales will, on the one hand, drive a need for far more packaging but will also need to answer consumers’ demands for sustainable products and packaging.