Contents

- Introduction

- Key innovation trends

- Sustainability Awards 2022 finalists and winners

- A statistical breakdown of Sustainability Awards 2022 submissions

- Winners of other major competitions

- Full list of Sustainability Awards 2022 submissions

Introduction

This report provides insights into the nature of sustainable packaging innovation at the present time, as seen from Packaging Europe’s viewpoint. It draws on several data sources.

The most significant of these is the latest edition of the Sustainability Awards competition, which is organized by Packaging Europe, and in 2022 attracted 357 entries that met the submissions criteria.

The volume and breadth of these entries provide some basis to begin to generalize about the key major drivers of sustainable packaging innovation, while the independent judging panel’s remarks and collective verdicts provide insights into the types of innovation leading thinkers and decision-makers in the international packaging community consider most significant.

In addition to the catalogue of innovations provided by the Sustainability Awards competition, this report references innovations that the Packaging Europe team has encountered in the course of its year-round journalistic activities and reporting, including hundreds of hours of discussions with experts. We also spotlight some relevant products that have been recognized for their environmental impacts by other packaging innovation competitions.

It must be acknowledged that while Packaging Europe’s activities and ambitions are global, the picture provided in this report is incomplete and rather Euro-centric. (While the Sustainability Awards is the largest global packaging competition, for example, and with submissions from every continent, it is undeniably imbalanced in favour of Europe. Outreach to encourage greater engagement across other regions of the world is ongoing.)

We hope, however, that the level of detail in the report provides a useful resource for anyone with a serious interest in packaging sustainability. This document consists of several sections. In the first, we describe key innovation trends Packaging Europe has observed. This is followed by details of the Sustainability Awards finalists and winners, statistical breakdowns of this year’s competition, a full list of 2022 submissions, and a selection of innovations celebrated by other initiatives.

This article is part of Hive - Packaging Europe’s new subscription community - which will be launched very soon. Stay tuned for further details!

Key innovation trends

In this section we draw from the Sustainability Awards submissions data and Packaging Europe’s wider reporting to provide an overview of the current headline trends informing sustainable packaging innovation. Among the examples we have cited in the following sections are several of the Sustainability Awards 2022 winners or finalists, reflecting the endorsement from the competition’s independent judging panel that these represent significant contributions to the market, as well as some important product developments highlighted by the juries of other initiatives.

Paper alternatives

In the context of fierce attention on unrecycled plastic waste, there is growing demand for alternative paper solutions across a range of packaging solutions. This is driving considerable investment in innovation in fibre-based packaging with particular focus on extending barrier properties, durability and machinability. Over the last two years, the Sustainability Awards has reflected a range of innovations in this field, including flexible packaging, paper bottles and caps, corrugated multipack aggregation solutions, moulded pulp formats and paper-compatible machinery solutions. Sometimes a shift to fibre-based packaging does not require innovation in the materials, but use of existing paper-based materials in new structural designs – some such examples can be found in the ‘Format Redesign’ section below.

Among the finalists in this year’s Sustainability Awards were entries representing both of the big two competing paper bottle platforms, Paboco and Pulpex. Whether the paper bottle format is destined to be a niche product or replace plastic at scale remains to be seen. There are also open questions, and controversy, around whether ongoing R&D can meet the challenge of full recyclability within the paper waste stream.

Paboco’s bottle, featuring a paper outer shell with a thin plastic barrier inside, has been a much-anticipated addition to the market since its inception in 2015. The bottle has now been trialled by companies including Carlsberg, Coca-Cola, and Absolut. The latest prototype of the bottle also features a paper closure from Blue Ocean Closures, with the rollout for brand applications including cosmetics, home care, and still drinks expected in 2023.

Meanwhile, Unilever has launched a paper-based laundry detergent bottle the for laundry brand OMO (also known as Persil, Skip & Breeze). The bottles are sprayed inside with a proprietary coating that repels water, enabling the packaging material to hold liquid products like laundry detergent, shampoo, and conditioners, which contain surfactants, fragrances, and other active ingredients. This technology has been developed in partnership with the Pulpex consortium, a collaboration between Unilever, Diageo, Pilot Lite, and other industry members. Unilever says it is also piloting the same technology to create paper-based haircare bottles.

Elsewhere, traditional moulded fibre producers already manufacturing at scale, such as Cullen Packaging, are recognizing market interest in the paper bottle format and creating new offerings for a range of loose, non-liquid products that do not require problematic liquid barriers.

Plastic caps and lids are major contributors to single-use plastic waste in the natural environment. The above-mentioned paper closure from Blue Ocean Closures is a collaboration with Glatfelter, utilizing renewable wood fibres to create cellulose-based screw caps as an alternative to plastics. The caps can be recycled in the paper stream and are, according to the company, completely biodegradable in soil and the ocean. Blue Ocean Closures is working with The Absolut Company (Pernod Ricard) to develop a cellulose-based screw cap for Absolut Vodka’s bottle, with plans to launch commercially in 2023.

Meanwhile, Stora Enso has released its Cupforma Natura Aqua+ material which can be converted into paper cup lids for foodservice applications, such as coffee cups. The company says it is recyclable in existing paper streams and compostable in industrial settings. The material features a double-sided, water-based dispersion, replacing the traditional plastic layer. The material reportedly does not absorb liquid during use, adding to its suitability for foodservice applications.

Stora Enso has also recently launched Papira, a lightweight foam which it says is a fully recyclable, biodegradable alternative to fossil-based foam materials in packaging. Papira is expected to replace fossil-based, polymeric packaging foams such as polyethylene, polyurethane, and expanded polystyrene. The solution is still in the process of being assessed for recyclability and biodegradability certifications, and its carbon footprint is currently being measured to identify ways to improve its sustainability.

When it comes to resource efficiency, sealability is as important as barrier functionality. Coveris Flexibles has been collaborating with paper manufacturer Brigl & Bergmeister to develop PaperBarrier Seal, a paper-based food packaging material with a paper coating which the company says enables sealability. According to Coveris, PaperBarrier Seal is fully recyclable in existing paper streams and offers the same functionality and product protection as existing alternatives, including plastic.

Alongside the need for food protection and recyclability, another challenge for paper packaging is machinability. One solution recently developed to address this is a horizontal forming shoulder for paper with asymmetrical seams by FormerFab GmbH, which aims to make it easier for brands to switch to paper solutions without compromising on performance. The novelty of this solution, according to this company, is that while paper-based flow packs generally include a central longitudinal seam, its development of an ‘off-centre’ longitudinal seam gives the same opportunities for paper packaging as plastics.

Collaborations between machinery suppliers and packaging producers are also key when it comes to developing paper alternatives to plastics. In the area of e-commerce, Mondi has partnered with the German machine supplier beck packautomate n to launch FunctionalBarrier Paper, a flexible paper-based packaging solution that provides protection against water vapour and moisture during the transport of products for online retail and is recyclable in existing paper waste streams. According to Mondi, FunctionalBarrier Paper can replace plastic packaging for e-commerce applications and creates right-sized packaging for a wide range of products.

Mondi also recently brought the kraft paper based Advantage StretchWrap to market – an alternative in certain palletizing applications to plastic stretch film.

Finally, a migration from plastics to paper in flexible packaging continues to take place across multiple market segments and geographies. A notable recent example, acknowledged by the Asia Star awards, is Kolmar Korea’s Papertube the cosmetic pouch.

Monopolymers

Flexible packaging needs to meet a range of packaging functionalities, depending on the product to be packaged – gas and moisture barriers, antimicrobial properties, stiffness and so on. In the past, the necessary resource efficiency has been achieved through the use of multilayer materials but these are highly challenging to recycle in existing waste streams. Initiatives such as CEFLEX – which is spearheading the transition to and creation of a viable circular economy in flexible packaging in Europe – have mapped out guidelines for recycling-ready monomaterial-based flexible substrates. Industry has responded with a number of innovations in recent years – far too many to list them all here, but we give some recent examples.

Much of the low-hanging fruit in redesign for recycling has already been plucked, so that we increasingly see innovation focusing on the more demanding flexible packaging applications. The pharmaceutical sector, with its necessarily stringent requirements when it comes to security, consumer safety and product protection, poses particular challenges when it comes to monomaterial substrates. Amcor Healthcare’s recent AmSky blister system is a recycle-ready blister package with thermoformed bottom web and lidding. Both elements are made from HDPE, which allows for whole-package recyclability – an industry first.

Also active in the pharmaceuticals space is Constantia Flexibles, which recently introduced a recycle-ready, monomaterial PP laminate – PERPETUA ALTA – with high chemical resistance for pharma applications. The company says this solution can replace the multimaterial packaging for chemically aggressive products such as pharmaceutical liquid and hydro-alcoholic gel compositions while following ‘Design for Recycling’ guidelines. The solution can reportedly withstand challenging pharmaceutical applications with a similar performance to aluminium-containing multimaterial laminates compliant with HCR requirements.

Huhtamaki has announced the launch of Push Tab, an aluminium-free, monomaterial PET blister lid for the healthcare and pharmaceutical industries. The company says the reason this represents a major step forward is that it is the market’s first-ever recyclable unit dose packaging for pharmaceutical solid products. Push Tab adds a push-through function to strip packaging, creating a viable alternative for the ubiquitous blister packaging – something that has so far eluded the market.

Meanwhile, progress is being achieved in difficult food packaging applications, for example, over recent years mono solutions for retort applications have entered the market. Modified-atmosphere packaging has also presented challenges as it is traditionally problematic to recycle; Mondi has recently introduced Mono Formable PP, a recyclable high-barrier MAP solution made from mono-PP. According to the company, Mono Formable PP weighs around 30% less than a comparable polyester (PET) tray at the same thickness while offering the same high level of product protection. It also says it can act as an alternative to the industry standard of multimaterial non-recyclable PET trays.

Celebrated by the Sustainability Awards judges in 2022, Taghleef Industries and Gerosa Group have developed a recyclable PP-based barrier sachet for high product protection and easy tear opening, capable of replacing traditional multimaterial structures made of PET/Alu/PE or PET/metPET/PE.

In addition to replacing multimaterial flexible structures, we are seeing some interesting examples of simplifying the materials contained in rigid packaging that consists of more than one part. Some of these can be seen in niches such as complex dispensing mechanisms, whose multiple components have in the past required the use of multiple materials. Recent times have seen the introduction of innovations eliminating metal springs and removing silicone from membranes.

A finalist in this year’s Sustainability Awards was Liquibox, which has developed what it says is the first recycle-ready bag-in-box packaging for sensitive products, combined with its monomaterial VINIflow dispensing tap. According to the company, Liquipure eliminates the need for non-recyclable materials while still exceeding performance requirements.

A dispensing solution specifically for the needs of the booming e-commerce sector is Aptar’s Future monomaterial pump – winner of a 2022 Sustainability Award. This solution is fully recyclable when paired with a PE or PET bottle. Its suitability for e-commerce is down to its incorporated locking/unlocking ring, and it features a 360°, free spinning actuator which helps minimize potential breakage in transit.

The tubes market is also undergoing simplification. For instance, Albéa has launched EcoFusion Top, a two-in-one HDPE cap solution for tubes for personal care applications, which reportedly offers a ‘significant’ weight reduction compared to standard tubes. The single open-and-close system reduces the tube’s components to only two, the tube and the single cap, which the company claims make its 80% lighter than standard head and cap solutions. EcoFusion Top is also made from HDPE to guarantee monomateriality and help to enhance its recyclability.

Renewable feedstocks

While there have been some important steps towards building a circular economy for fossil-based plastics, they’re not in themselves renewable – hence the growing focus on developing bioplastics that are either recyclable or easily biodegradable. Bioplastics encompass a wide range of different materials, the most commonly used of which are PHA and PLA. According to the European Bioplastics definition, a plastic material is defined as a bioplastic if it is either biobased, biodegradable or both.

It is doubtful if we will ever see the same kind of uptake for bioplastics as we do for fossil-based – at the moment they only hold around a 1% share of the market – but investments in capacity introduction of novel feedstocks, together with innovation to extend functionality, will increase market share in future. It is, however, encouraging for the industry that several large brands, such as Nestle Waters and PepsiCo, have made commitments to grow the market size of bioplastics.

UPM Biochemicals is bringing a new generation of sustainably sourced renewable materials to market that it says will enable brands to redefine their net zero targets and switch out of fossil-based feedstocks. The company’s next-generation Bio-MEG renewable glycols technology was co-developed with The Coca-Cola Company and Changchun Meihe Science and Technology. It says the Bio-MEGs perform exactly like their oil-based counterparts, which means process redesign is not needed, and they integrate ‘seamlessly’ into existing manufacturing and recycling systems.

Bioplastics made from post-industrial and post-consumer waste utilizing chemical recycling techniques are also gaining interest. The latest update in this field from Total Corbion is its Luminy PLA, which it claims is the world’s first commercially available bioplastic product of its kind. The company says it receives and depolymerizes reprocessed PLA waste, which is then purified and polymerized into the new Luminy rPLA for commercial distribution. Early partners for the Luminy rPLA include Looplife in Belgium and Sansu in Korea, which have supported the collecting, sorting, and cleaning of post-industrial and post-consumer PLA waste.

Novel feedstocks are an increasing focus of research and development, although it should be restated that the market share for such materials is still very small. AIMPLAS, the Plastics Technology Centre, is working on developing bioplastics for active cosmetics packaging made from trees and shrubs, within the EU-funded BeonNAT Project. Specifically, as part of the project, AIMPLAS will produce PLA from lactic acid, which will be obtained from fermentable sugars in plant biomass waste and used as a bioplastic to make packaging for cosmetics. Essential oils with different active properties, such as antimicrobial power, will be added to this packaging.

Elsewhere, Dama Bioplastics has developed what it calls the ‘only truly sustainable, 100% hemp-derived’ bioplastic that is designed for injection moulding applications and, it says, is also home compostable. Derived from waste biomass, Dama’s bioplastics are designed as a drop-in solution for petroleum-based products.

Another novel feedstock-derived material is FlexSea, a ‘carbon-negative’, home-compostable biomaterial derived from cultivated seaweed and other natural additives that its producer says has the potential to replace single-use flexible plastic packaging in dry applications. According to the company, FlexSea’s decomposition does not harm the environment – rather, the high nitrogen content in seaweed fertilizes the soil, promoting healthy growth of nearby vegetation.

There are important questions around the desirability of compostable substrates as an alternative to materials that can be recovered and recycled. However, there is consensus that compostables are a good solution where contamination of the packaging by food residues make it unsuitable for the packaging waste stream. Single-use coffee capsules are a growing challenge in this context, and one exacerbated by the global pandemic, when more and more consumers took to purchasing at-home coffee machines. Compostable capsules represent a solution, and the Nespresso-compatible capsules made from Solinatra, a biomaterial alternative to single-use plastic made using agricultural plant waste, present a recent addition to the market.

In addition to creating plastics from renewable feedstocks, it should be noted that the Sustainability Awards registers a considerable market activity in harnessing untapped organic waste streams to produce fibre-based packaging. One finalist from the 2022 competition is Ukraine’s Re-Leaf, which has developed technologies to produce packaging-grade papers from the thousands of tonnes of fallen deciduous leaves collected in urban municipalities: an opportunity to turn a waste challenge into a valuable resource. Another is the collaboration between AB InBev and Sustainable Fiber Technologies to create secondary packaging for Corona beer incorporating barley straw waste.

Reducing footprints in production

Proponents of ‘infinite’ materials, glass and metals, argue that they are the most sustainable choice as they are entirely natural and – theoretically at least – endlessly recyclable. But life-cycle analysis indicates that glass and metals consume significantly more energy, with associated carbon emissions, in the production process than plastics. Attempts to improve the performance or reduce the environmental footprint of all substrates – and this includes plastics, too – have focused on areas such as cutting CO2 in the production process or lightweighting.

Turning first to metal substrates, tinplate manufacturer thyssenkrupp Rasselstein, together with Hoffmann Neopac and Ricola, has launched the world’s first food can made from CO2-reduced Bluemint® Steel. With the Bluemint manufacturing process, in addition to the 100% recyclability of steel, the companies say considerable savings (up to 70%) are also made on CO2. It’s also an example of a successful cross-value chain collaboration: Thyssenkrupp supplies the steel for the project, Hoffmann Neopac produces and prints the cans using solar power and Ricola relies on energy from renewable resources for the production and filling of its herbal drops.

Another example of the benefits to be gained from collaboration is ‘the world’s lowest-carbon aluminium beer can’ developed by AB InBev, Rusal, Canpack, and Elval. According to the project partners the can is made with 100% renewable electricity and uses an inert anode technology that allows for reduced emissions.

Moving on to glass: in January 2022, Dassault Systèmes, Ardagh Group, and EXXERGY commenced ‘industry-first virtual twin’ trials to test the use of a technology that reportedly increases the strength and reduces the weight of glass bottles, starting with Diageo’s Johnnie Walker scotch bottle. The trial will research and develop a new external coating for glass bottles, which will apparently reduce the naturally occurring micro-cracks in the glass surface and make the glass much lighter. The new technology will, according to the companies, reduce the raw materials and energy used in the glass melting process. The trial is ongoing, but if results are positive, it could prove significant for overall perception of glass packaging.

Already on the market, the Aurelia bottle by Berlin Packaging is a carbon neutral wine bottle produced using renewable energy sources – biomethane instead of natural gas – with an offsetting programme for the remaining CO2 emissions. Through this, says the company, any additional CO2 generated in production is offset.

Finally, while metals and glass tend to occupy the spotlight when it comes to carbon intensity of production, there is always scope to improve the resource efficiency of plastics. Keiryo Packaging Technologies is developing a polymer processing technology to reduce the environmental footprint and manufacturing cost of plastic packaging. Keiryo uses a 3D printed insert that can be retrofitted on existing injection stretch blow moulding (ISBM) machinery to introduce a controlled mechanical energy into the polymer melt during its processing. Consequently, the molecular organization of the polymer melt is altered with the creation of flow-enhanced morphological structures. This, says the company, enables light weighting, better barrier performance and improved mixing of virgin and recycled material.

Format redesign

Whichever material is used, design is a fundamental aspect of a pack’s sustainability. Whether it’s the shape of the pack itself – flat wine bottles were a celebrated example of recent years – making a pack more easily separable for improved recyclability, or more innovative use of certain materials, there are many, many avenues to explore. The overall aim, in every case, is to reduce the overall environmental footprint of a package and, where possible, eliminate waste.

We continue to see good examples of packaging that facilitates easy separation of materials – not itself a new trend. Greiner Packaging’s K3 r100 self-separating packaging system was nominated as a finalist in the Readers’ Award category of the Sustainability Awards: a plastic cup and cardboard wrap that autonomously separate in waste collection to increase recycling rates. Another Sustainability Awards finalist was Procter & Gamble’s Lenor Fabric Enhancer bottles in Germany, Austria and Switzerland, which featured full body removable, double perforated sleeves. This packaging further boosted its sustainability credentials by using 100% recycled PET in the bottles, and incorporating digital watermarks.

Meanwhile, Australia’s O F Packaging devised an ingenious way to ensure that its ‘recycle ready’ mono flexible packaging could actually be recycled in current conditions. Since through kerbside collection, the flexible pack would risk being incorrectly sorted into the paper recycling stream, O F Packaging came up with a design that could be rolled into a cylinder by the consumer, and fixed in its three-dimensional shape, in order for it to be sorted with rigid plastic containers into the correct stream.

Another innovative packaging solution addresses not only the need for sustainability but also accessibility and security. PopPack’s EasyPop solution allows flexible and semi-rigid packaging to be opened with the pop of an air bubble incorporated into its design, replacing difficult-to-open seals. According to the company, what’s innovative about EasyPop is that it is part of the primary packaging, while bubble wrap and other air-based solutions often comprise the secondary and tertiary packaging.

It also, says PopPack, eliminates the need for tear strips, which are often placed in the incorrect disposal stream, and reduces material waste and weight as packages no longer require caps. The air bubble system can also be configured to allow resealing, so packaging can be reused, and the freshness of food and beverages can be maintained for longer.

Packaging format redesign has proven particularly important in the e-commerce space, where the need to reduce the carbon footprint during transit is that much higher. WestRock’s fibre-based mailer solution, KD-fold™, is a kerbside recyclable replacement for single-use plastic mailer bags. It consists of a tube-shaped, single-face corrugated fanfold packaging substrate designed to be fed into an automated system to produce custom-sized mailers for e-commerce and shipping needs.

Also in the e-commerce space, Smurfit Kappa has developed a corrugated packaging solution that allows FMCG company Reckitt to distribute its brands via Amazon without single-use plastic blisters or fillers. The companies claim this solution replaced over 130 tonnes of single-use plastic blisters in 2020 and 2021 with 100% paper-based packaging, which generates 17.5% less CO2 emissions and has less impact when littered compared to polyethylene (PET).

The EcoCubly modifiable box is designed to create efficiency in transit. It has been created with a closure mechanism that allows for easy size adjustment according to the product being packed – addressing the problem of ‘empty space’ that comes with standard transit packaging sizes. EcoCubly says its design is also more robust and durable than conventional packaging solutions, allowing it to be easily reused and offering protection against transport damage.

Material elimination

Multiple reports have indicated that industry will be unable to recycle its way out of the packaging waste crisis, and the prevailing direction of regulation emphasizes that we must shift faster and on a greater scale toward elimination of packaging materials where possible. As such, we have seen ever more examples of innovation around reuse / refill models in consumer goods.

A high-profile example over the last three years has been TerraCycle’s Loop platform for brands to offer products in reusable containers. The last year has seen in-store collaborations between Loop and Tesco, piloting a way for customers to buy products in reusable packaging that can be returned to the store to be cleaned, refilled and reused.

As part of the trial, which came to an end in June 2022, Tesco offered prefilled reusable packaging for 53 branded lines and 35 own-brand products including food staples like pasta, personal care essentials like washing liquid, confectionery, and beverages. This means that the product was provided pre-packaged in Loop containers. After use, the customer was responsible for returning the packaging to the store, and Tesco then oversaw the cleaning and refilling of the containers via a third party for future reuse.

SuperShelf™, a collaboration between FillX and Quantex, is a liquid dispensing system that ’makes refill a viable option for brands and accessible for mass customers adoption’. It is an intelligent, user/retail friendly dispensing system allowing consumers to re-use their existing container by refilling. The brand owner packs a larger volume of any viscosity liquid in to a Bag-in-Box which sits on top of the SuperShelf™, and the existing plastic container can then be refilled at the press of a button.

Ecorefill by Beiersdorf’s NIVEA brand not only provides a refill solution but also allows the weight of the product itself to be reduced in transit. It consists of a foam soap made with dissolvable tablets to be mixed with water in a 100% rPET, refillable bottle. Additionally, the cleanser tablets are packaged using FSC-certified paper, in order to reduce the use of fossil-based materials and promote plant-based alternatives. For consumers, the process involves filling the bottle with water up to the line indicated on the pack. After adding the refill tablet, the bottle should then be closed with the pump and shaken for 30 seconds.

There have also been a number of refill solutions in the cosmetics space. The Recharge by Fasten BV is a cosmetic refill packaging concept which is designed to promote circularity by reducing material, reusing the bottle, and enabling ease of recycling. The Recharge Luxury Refill is made entirely from PP and PET and the design also includes an all-PP cosmetic pump – reportedly the first of its kind on the market. Fasten says that the Recharge Luxury Refill System features a bottomless, clear outer frame, instead of a full outer bottle, which apparently allows for reduced weight and material use, as well as full visibility of the refill. In addition, the inner refill bottle is lightweight and features an easy click-in system with a pre-assembled PP dip tube that prevents cross-contamination when refilling.

PAPACKS® Refill-CAP, a WorldStar winner in 2022, features a paper-based refill containing cream and/or cosmetic content which is inserted into a durable glass jar. Meanwhile, Quadpack and Aptar Beauty + Home have jointly developed a refillable lipstick, the Iconic Woodacity® Lipstick, that combines their respective expertise in wood and stick mechanisms. The stick mechanism is contained in a monomaterial casing custom-designed and manufactured by Quadpack. To refill, consumers simply pull out the used mechanism and snap in the new one. They can also keep various colours and insert the one they want to use that day, further reducing the pack’s impact.

Another important trend is the shift to waterless formats: a primary product adaptation that eliminates the shipping of water while simplifying the packaging demands and volumes. An outstanding example of this trend, and an important step in mainstreaming a niche application is Procter & Gamble’s shampoo and conditioner bar.

Transparency & benchmarking

There is an increased emphasis on the need for companies to transition to circular business models. For efforts in this direction to make the desired impact, they must be quantifiable and the processes behind them must be clear to see. Benchmarking tools are therefore a key part of the drive towards sustainability, as are the development of solutions such as open-source platforms that can make relevant data available along the entire supply chain to increase recyclability. Here are just a few that are currently in use or expected to become available in the coming months.

CO2 AI by Boston Consulting Group is an end-to-end, ready-to-deploy, AI-powered digital solution that it says corporations from all industries can use to quantify emissions accurately — and find solutions to reduce them at scale. According to the group, CO2 AI addresses a key challenge for companies aiming to cut their CO2 emissions: just 9% of companies measure their emissions comprehensively, and just 1% reduce their emissions in a way that is in line with their targets. It says it has successfully implemented CO2 AI across diverse industries, enabling them to reach up to 30-50% more accurate footprint calculations and 30-40% emissions reduction.

The Institute cyclos-HTP has developed the CHIRA recyclability assessment – a catalogue for requirements and evaluation (Catalogue R & A) for assessing and certifying the recyclability of packaging and goods. Intelligent query menus within the tool for individual packaging types enable the user to evaluate packaging which can be created in the packaging archive. The assessment is performed for all material types with EU-wide scope in national differentiation in conformity with the German minimum standard and ISO 14021.

Australian retailer Coles’ Sustainable Packaging Data Project gathers information about packaging recyclability from the company’s suppliers to facilitate the reduction or elimination of what it identifies as ‘problematic packaging’. Coles has worked closely with its suppliers MSAC Solutions, PREP Design and the Australian Packaging Covenant Organisation (APCO) to gather detailed packaging information from Coles Own Brand suppliers to assess its recyclability in Australia, with the aim of supporting industry towards Australia’s 2025 National Packaging Targets.

SCALIZE is a new cloud-based tool for packaging developers to instantly analyze packaging dimensions with their project teams, simulating tolerances and capabilities to enable ‘holistic’ design decisions for sustainability. SCALIZE analyzes packaging designs via both volume and dimensions, identifying minor adjustments that it says yield on average +20% more units per pallet.

Transparency and data-sharing, as mentioned above, are also vital for building sustainability into the entire value chain. The packaging data platform R-Cycle – a ‘digital product passport’ – automatically collects and provides recycling-relevant data via an open standard format during production and makes it accessible for improved waste sorting.

The Packaging Cockpit is a tool that calculates the technical recyclability, as well as the life cycle assessment of packaging systems. The calculations can be performed for different countries, allowing country-specific evaluations. The goal of the tool is to increase the transparency of packaging systems, helping companies to make the right decisions when it comes to optimizing their product portfolios. The Cockpit can be applied both internally within companies and to entire supply chains.

Perhaps the technology ecosystem with the most exciting potential in this category is digital watermarking: adding a barely visible code to the printed artwork or mould, which can then be read by smart cameras. The multistakeholder HolyGrail 2.0 project, which is attempting to realize improved sorting of packaging in recycling centres through digital watermarking, has proceeded from proof of concept to increasingly high volume industrial testing, with very encouraging results.

Beyond the potential to boost recyclate purity by retrofitting sorting lines with cameras that can read watermarks, the technology has huge potential to add value to stakeholders at every touchpoint across the supply chain, since any smart-connected camera can read the watermarks, individual product serialization is possible. Opportunities span consumer engagement, tracking within the supply chain, and data transparency, which could enable brands at enterprise level to meet future reporting requirements around the percentages of packaging waste recovered and recycled.

Sustainability Awards 2022 winners and finalists

Finalists in the Sustainability Awards 2022: Main categories

Submissions to the categories must either be from products that are already in commercial use or broader initiatives. Winners were announced at the Sustainable Packaging Summit in Lisbon on 13th September 2022.

Driving the Circular Economy

The Driving the Circular Economy category promotes innovations around recycling, reuse and increased utilization of recycled content, as well as initiatives that strive for higher recycling rates. Past winners of this category include two Sustainability Awards overall winners, from 2021 and 2019: the NEXTLOOPP project, creating food-grade packaging from recycled polypropylene, and the first generation of the HolyGrail project, validating the potential of digital watermarking to improve sorting.

WINNER: R-Cycle – digital product passport for sustainable plastics

R-Cycle (Germany)

As a packaging data platform, R-Cycle automatically collects and provides recycling-relevant data via an open standard format during production and makes it accessible for improved waste sorting.

Finalists:

CRYOVAC® brand rBDF20M

Sealed Air (UK)

Recycled-content food-grade flexible packaging, with reduced EVOH quantity, making the material compliant with OPRL Return to Front of Store for flexible film recycling.

Liquipure® mono-material VINIflow® dispensing tap

Liquibox (USA)

Enabling restaurants, institutions and household consumers to recycle bag-in-box packaging for sensitive products, removing plastic from landfills.

NIVEA ecorefill

Beiersdorf (Germany)

ecorefill is NIVEA’s first foam soap made with dissolvable tablets to be mixed with water in the recycled and refillable bottle.

Reuse system supermarket pilot

Loop & Tesco (UK)

Tesco and Loop are piloting a way for customers to buy products in reusable packaging that can be returned to store when finished to be cleaned, refilled and used again.

Climate

The ‘Climate’ category, newly introduced in 2022, replaces the former ‘Resource Efficiency’ section of the awards (previous winners of which included HelloFresh for their use of big data to optimize packaging consumption and Maison Ruinart’s ‘Second Skin’ paper champagne case). Finalists in ‘Climate’ category are selected as excellent examples of packaging innovation that can reduce the carbon footprint of the materials used or the packaged product itself.

WINNER:Technomelt® Supra ECO carbon-negative packaging hot melt

Henkel (Germany)

The first carbon-negative hot melt adhesive helps to move to a negative carbon footprint for the same adhesive consumption. Technomelt® Supra ECO is an adhesive made from 81% bio-based material, providing full traceability of its carbon footprint and sustainable sourcing of raw materials, thanks to a certified mass balance approach.

Finalists:

Aurelia wine bottle

Berlin Packaging & Bruni Glass (Italy)

Aurelia is a ‘Carbon Neutral’ bottle from the Itinera collection, using electricity from renewable sources, biomethane instead of natural gas, a programme dedicated to offset residual CO2 emissions, and increased PCR content.

Bluemint® Steel pure

Hoffmann Neopac, thyssenkrupp Rasselstein & Ricola AG (Switzerland)

Ricola cough drops are packaged in a tin with up to 70% CO2 savings, using carbon-reduced bluemint® steel. Savings are achieved not by buying compensation certificates, but by reducing carbon emissions through sourcing and renewable energy.

Low-carbon aluminium can

AB InBev, Rusal, Canpack, Elval (Belgium)

The world’s lowest carbon aluminium beer can, using renewable electricity and produced from aluminium coils manufactured by Elval. The metal is made with inert anode technology, which generates one thousandth of the current average emissions for the industry, and mixed with recycled aluminium.

Renewable Materials

The ‘Renewable Materials’ category aims to promote the development or innovative use of renewable, organically-derived materials with significant positive impact or potential in packaging applications.

WINNER:UniNATURE Packaging inks with high bio renewable content

Siegwerk (Germany)

A new generation of water-based inks with up to 50% renewable carbon content. This represents an alternative to conventional inks without impacting the recyclability of paper and board packaging taking a step towards reducing the microplastics which can be found in inks.

Finalists:

Omnifoods frozen ready meal range with home compostable trays

Green Monday (Hong Kong)

Compostable, biodegradable and microwaveable bagasse trays for various affordable plant-based Omnifoods frozen/chilled meals introduced across over 700 convenience stores.

Paboco - the Paper Bottle

Paper Bottle Company (Denmark)

An innovation community united by the mission to create a fully bio-based and recyclable paper bottle at scale. Paboco’s next generation paper bottle comprises made from FSC-certified wood fibers together with a minimal PE-coating (33cl bottle has 2.5g coating and 15g paper), featuring paper threaded neck, paper closure, and recyclable in the paper recycling stream.

Re-Leaf Paper

Re-Leaf Technology (Ukraine)

Paper packaging made from fallen leaves. A unique technology turns deciduous biomass into paper, helping cities on their way to carbon-neutrality. This addresses the problem of the utilization of plant waste in the urban ecosystem and preserves the integrity of forest ecosystems.

Best Practice

The purpose of the Best Practice category is to identify ideas, solutions and initiatives beyond innovation in packaging itself that significantly contribute to minimizing the environmental impact of packaging and its supply chain. Previous winners include the circular economy collaboration between Searious Business and supermarkets in Morocco, and Henkel BeautyCare for its Social Plastic ecosystem.

WINNER: CO2 AI by BCG

Boston Consulting Group (France)

CO2 AI by BCG is an end-to-end, ready-to-deploy, AI-powered digital solution that corporations from all industries can use to quantify emissions accurately—and find solutions to reduce them at scale.

Finalists:

Building collection systems in Africa

Equatorial Coca-Cola Bottling Company (Morocco)

Creating collection systems to ensure circular economy for packaging, while promoting recycling awareness within the communities of Guinea and Morocco, working with local partners and adapting to market reality.

Optimizing design dimensions

SCALIZE (Germany)

SCALIZE is a new cloud-based tool for packaging developers to instantly analyze packaging dimensions with their project teams, simulating tolerances and capabilities for the most holistic design decisions for sustainability.

Sustainable packaging data project

Coles Group (Australia)

A collaboration with MSAC Solutions, PREP Design and the Australian Packaging Covenant Organisation (APCO) to gather detailed packaging information from Coles Own Brand suppliers to assess recyclability, supporting industry towards Australia’s 2025 National Packaging Targets.

Recyclable Packaging

The recyclable packaging category celebrates innovations in packaging materials to facilitate recyclability or are designed for circularity. Previous winners in this category include Nestlé’s switch to paper packaging for Smarties and Bericap’s silicon-free valve.

WINNER: Amcor HealthCare™ AmSky™ Blister System

Amcor (USA)

An industry-first, recycle-ready blister package with thermoformed bottom web and lidding both made from HDPE allowing whole-package recyclability.

Finalists:

Heat-resistant and fully recyclable sheet material

Starlinger viscotec (Austria)

rPET100 sheet material for thermoformed packaging is a game-changer for circular packaging solutions: it is designed for recycling, and made from recycled PET.

Removable, digitally watermarked sleeves for Lenor

Procter & Gamble (Belgium)

In Germany, Austria and Switzerland, opaque PET bottles opaque Lenor Fabric Enhancer PET bottles were replaced by 100% recyclable and recycled PET bottles with full body removable, double perforated and floatable sleeves with Digital Watermarks.

Re-using packages faster with RAIN RFID

Confidex & CupLOOP (Finland)

Automated collection and deposit refund for reusable packages making re-using packages faster and more easily through asset tracking, deposits, and instant reimbursement.

E-Commerce

The E-Commerce category considers innovations delivering holistic sustainability gains in e-commerce and direct-to-consumer channels. The previous winner of the category, which was introduced to the Sustainability Awards in 2021, was CMC’s Genesys , which allows customers to feed and pack multi-line orders without the requirement to be strapped or wrapped together.

WINNER: Future pump

Aptar (Italy)

A mono-PE, recyclable e-commerce compliant pump. This modern take on closure design meets the rigorous ISTA 6-Amazon protocol, ensures that the pump withstands the pressures of distribution while necessitating less protective carton and paper packaging.

Finalists:

The envoBOX

envoPAP (UK)

A box produced from discarded agricultural fibres that would otherwise be burnt and pollute the planet in many ways.

KD-Fold™ customized mailers

WestRock (USA)

WestRock KD-Fold™ is a proprietary tube-shaped, single-face corrugated fanfold packaging substrate is designed to be fed into an automated system efficiently producing custom-sized mailer solutions for e-commerce and shipping needs.

Reckitt e-commerce sustainable packaging for Amazon

Reckitt and Smurfit Kappa North America (USA)

Reckitt’s new e-commerce sustainable solution for Amazon avoids single-use plastic and complies with the eCommerce requirements while also improving customer satisfaction and brand perception.

Systematic Cooling Concept

HelloFresh (Germany)

The Systematic Cooling Concept (SCC) is an in-house build and innovative packaging solution which amongst other aspects, ensures the packaging efficiency and optimal thermal performance stability of products.

Machinery

The ‘Machinery’ category promotes innovations in engineering that have more efficient and environmentally friendly production lines (energy and water consumption or waste reduction) or enable the transition to more sustainable packaging formats and materials. Previous winners include watttron for its digital sealing solution, Syntegon’s PaperForming technology, and BOBST’s DigiColor inking system.

WINNER: Cyclone C4+ can printing

Tonejet (UK)

A direct-to-can electrostatic inkjet digital printing system for beverage can decoration. This enables beverage producers releasing shorter runs to eliminate use of printed labels or shrink sleeves that can complicate recyclability of cans.

Finalists:

Horizontal forming shoulder for paper with asymmetrical seam

FormerFab® (Germany)

Flowpack forming shoulder for forming paper with an asymmetrical seam for primary and secondary packaging without destroying paper barriers. This innovation supports customers’ transition to paper packaging.

Hybrid ASD technology

CCL Label (Germany)

Hybrid ASD (any stage differentiation) printing technology reduces carbon footprint compared to other printing techniques, while facilitating unique design goals to make the product stand out on shelf.

Snapcut for PET form fill seal cups

Barry Wehmiller Packaging Systems (France)

Synerlink’s patented Snapcut technology enables dairy and food processors using form-fill-seal technology to cut and pre-cut PET, PP, and all other recyclable and recycled plastics such as PLA and rPET.

Readers’ Award

The Readers’ Award category differs from the rest of the Sustainability Awards, as the judging panel is not involved. Instead, Packaging Europe’s audience gets to nominate the innovations that have most impressed them over the last year and, having created the shortlist, to vote for the solution they consider most important. Previous winners include P&G’s reusable aluminium haircare bottle, Beiersdorf’s Nivea refill station, and Nestlé’s paper wrapped YES! Snack Bars.

WINNER: SealPPeel packaging

Vandemoortele & MCC Verstraete

Heat seal die-cut lidding replacing aluminium to create a fully mono-material, polypropylene pack.

Finalists:

Fibre-based coffee cup lid material

Stora Enso

Improved recyclability thanks to cup and lid both being suitable for the paper waste stream.

K3 r100 self-separating packaging system

Greiner Packaging

Plastic cup and cardboard wrap that separate autonomously in waste collection to increase recycling rates.

OMO paper laundry bottle

Unilever & Pulpex

The first-ever paper-based laundry detergent bottle.

Shampoo and conditioner bar

P&G

A primary product adaptation that eliminates the shipping of water and reduces the packaging footprint.

Finalists in the Sustainability Awards 2022: Pre-Commercialized categories

Submissions to these categories must be from packaging innovations that are not yet in commercial use.

Active and Intelligent (Pre-Commercialized)

After Opening Freshness Timer

Insignia Technologies Limited (United Kingdom)

Insignia Technologies have created the after opening freshness timer, an ink-based time temperature indicator providing consumers with a visual indication of how long food has been open, to prevent unnecessary food waste. The ink changes colour depending on the time elapsed since opening and storage temperature.

WINNER: ColorSensing (Spain)

ColorSensing helps food manufacturers and retailers reduce food waste through a QR-shaped smart label, containing intelligent inks that react to different parameters inside the package, and an algorithm that allows the label to be read automatically.

Mimica Touch Cap

Mimica and UNITED CAPS (United Kingdom)

Mimica and UNITED CAPS have collaborated on the Mimica Touch cap, a temperature-sensitive food freshness indicator which reduces waste caused by expiry dates. It is accessible to all due to the tactile surface of the cap, which turns bumpy when drinks should no longer be consumed.

SIPZ

STIRZ International Packaging Solutions (United Kingdom)

STIRZ has come up with SIPZ, natural ingredient dissolving beverage pouches made from allergen free, odourless and tasteless film used to encase products including ground coffee and protein powders.

StixFresh

Ryp Labs (United States of America)

Ryp Labs have designed StixFresh, a food-safe sticker you can peel and apply directly to fresh produce or its packaging at any point in the supply chain, to extend the shelf-life by up to 2 weeks.

Climate Category (Pre-Commercialized)

EcoCubly (Switzerland)

EcoCubly represents a size-adjustable packaging solution - a box with a closing mechanism consisting of four corresponding carton elements, allowing flexible space-saving adaptation to the content.

WINNER: Flexpenser (Sweden)

Flexspenser is a container which remains sealed while in use, aiming to extend home-life, retain the original quality and control the dispensing of liquids and semi-liquids for households and industries.

FlexSea (United Kingdom)

FlexSea is a carbon-negative biomaterial transparent film, derived from cultivated seaweed and other natural additives that has the potential to replace single use flexible plastic packaging in dry applications.

Pure-Pak eSense Aseptic carton

Elopak (Norway)

Elopak have made the Pure-Pak® eSense Aseptic carton for low and high acid products which is aluminium-free, made with sustainably sourced carton and a polyolefin blend barrier, opening up opportunities for a fully renewable aseptic carton.

Carbon-Negative Circular Economy Supply Chain

AB-Inbev, UBQ and Pisani (Brazil)

AB-Inbev partnered with UBQ Material and Pisani to reduce its carbon footprint by using UBQ™ material across its supply chain, a thermoplastic converted entirely from packaging materials diverted from landfill.

Driving the Circular Economy (Pre-Commercialized)

Certified circular PP in cat food packaging

SABIC, Mars Petcare and Huhtamaki (Netherlands)

SABIC, Mars Petcare and Huhtamaki have collaborated to produce wet cat food packaging pouches using certified circular polypropylene (PP), used for the SHEBA brand.

Keiryo Packaging Technology (Luxembourg)

Keiryo Packaging have devised a polymer processing technology that reduces the environmental footprint and manufacturing cost of plastic packaging, by retrofitting KP technology in existing injection machinery.

WINNER: polycirQ deinking process

polycirQ and Siegwerk Druckfarben (Germany)

The polycirQ deinking process is an advanced mechanical recycling process that removes printing inks from LDPE and PP films to prevent downcycling of valuable plastic resources.

SuperShelf™

FillX and Quantex Arc (United Kingdom)

FillX have partnered with Quantex Arc to develop a liquid dispensing system that makes mass integration and adoption of ‘refill’ a viable option within existing retail environments.

The Recharge

Fasten (Netherlands)

Fasten have created a sustainable cosmetic refill packaging concept aiming towards a circular economy through reducing material, reusing the bottle, and easy recycling of the packaging.

Recyclable Packaging Category (Pre-Commercialized)

Blue Ocean Closures Fibre Screw Caps

Glatfelter and Blue Ocean Closures (Sweden)

Blue Ocean Closures and Glatfelter have worked together to produce paper-based screw caps that are durable, strong and water-resistant, made of renewable and recyclable wood fibres and airlaid materials.

High barrier ready to recycle paper

Rotor Print (Spain)

Rotor Print have developed a 100% paper mono material with high barrier properties, grease resistance and heat sealable coating.

Recyclable oxygen barrier packaging

NOVA Chemicals (Canada)

NOVA Chemicals have produced a recyclable oxygen barrier packaging film solution to replace traditional EVOH-based coex materials and improve the quality of PE recyclate.

WINNER: Recyclable PP-based barrier sachet

Taghleef Industries and Gerosa Group (Italy)

Taghleef Industries and Gerosa Group have proposed a BOPP-based barrier sachet for high product protection and easier opening, to replace traditional multi-material structures made of PET, Alu, PE or PET, metPET and PE.

UPLIFT Plastics

Aalborg University (Denmark)

Aalborg University has come up with the UPLIFT Plastics project, which aims to biologically depolymerise bio and fossil-based plastic packaging waste in the food and drinks industry, and convert it into renewable polymers which can be upcycled, following a biorefinery approach.

Renewables Category (Pre-Commercialized)

WINNER: Barley Packaging

Anheuser-Busch InBev and Sustainable Fiber Technologies (Belgium)

AB InBev have developed a new technology from leftover barley straw, using straw pulping developed by Sustainable Fiber Technologies in combination with fully recycled wood fibres to create a high-resistance six-pack box.

PaperBarrier Seal

Coveris Flexibles and Brigl & Bergmeister (Germany)

Coveris Flexibles and Brigl and Bergmeister have devised PaperBarrier Seal, a recyclable, sustainably sourced packaging material with strong barrier properties which can be used for products such as dried fruits, cereals, and condiments.

Papira

Stora Enso Biomaterials Innovation (Sweden)

Stora Enso’s Papira is a wood fibre-based material with shock-absorbing and insulating properties, designed to be a renewable and paper-recyclable alternative to fossil-based foams.

UPM Bio

UPM Biochemicals (Germany)

UPM has developed a concept for the production of renewable glycols to help packaged goods manufacturers reach their net zero targets, by switching from a fossil-based to renewable option.

Statistical breakdown of Sustainability Awards submissions in 2022

Selected sustainable innovations recognized by international packaging competitions in 2022

The list below is compiled based on competitions with which Packaging Europe has sufficient familiarity that we can endorse their results on the basis of the integrity and independence of the judging process and expertise of the judges. We are aware that the list is not exhaustive. In some cases where the competitions below recognize multiple winners, we have included a partial selection based on the scope of this report.

German Packaging Prize

Organised by dvi.

Gold Award winners 2022:

-

A fundamental innovation in film laminating technology from POLIFILM EXTRUSION GmbH.

-

A remarkably sustainable and ingeniously child-safe box for washing tabs from Procter & Gamble Service GmbH.

-

An extremely weight-reduced and fully recyclable two-part PE monomaterial tube with a high PCR content from the Albéa Group in France.

-

Software for measuring and optimising recyclability from Institut cyclos-HTP GmbH.

-

An innovative pharmaceutical machine solution for the smallest batch sizes, high format flexibility and minimal operator intervention from Syntegon Technology GmbH.

-

An innovative pump dispenser with standard DIN thread and integrated dosing spoon, which means safe dosing especially for people with motor or visual impairments.

De Gouden Noot

Organized by the NVC (Netherlands Packaging Centre)

Gold Winner:

Modified Atmosphere Technology Masterpack Group

Silver Winner:

Capsule Dispenser PACKSYS GmbH

Bronze winner:

PET bottles from CO2 recycling Mibelle Group

WorldStar Awards

Organized by the World Packaging Organisation – only accepted from winners of WPO recognized packaging competitions, including the Sustainability Awards.

Winners of the Special Award: Sustainability in 2022

Gold Award

rPET school milk cup: fully recyclable cup made from recycled material

PET-MAN, Starlinger viscotec, Greiner Packaging

rPET school milk cups are made from 100% recycled post-consumer PET. After their use, the cups are collected at the schools and recycled into the same product again. This means (1) no downcycling, but closed loop recycling in food safe quality and (2) packaging waste is avoided.

To package locally produced dairy products in climate-friendly packaging creates added value in the region Upper Austria. The inherent aspect of recycling education (collection of used packaging in schools) and the promotion of regional agriculture complements the sustainable model.

As part of the project, a carbon footprint analysis was carried out to determine the emission saving potential of the new rPET cup. With 21 g CO2-equivalent per cup, the rPET cup clearly outperforms the previously used packaging options. At 34 g CO2-equiv./packaging unit, the PP plastic cups cause 21% higher CO2 emissions than the rPET cup. The PS cup and the returnable glass even cause 50% more CO2 emissions compared to the rPET cup, with 42 g CO2-equiv./packaging unit each. rPET is thus clearly the more environmentally friendly alternative. Full study available at www.rPET-cup.com

The use of recycled material, the short distances and the lower make the collection of the cups particularly CO2 efficient. In comparison to reusable glass bottles, rPET cups need less energy throughout production, they are lighter and require less energy to be cleaned / recycled, which results in -30% CO2 emissions.

rPET school milk cups are designed for recycling (unprinted, monomaterial) thus 100% recyclable. After use the rPET cups are recovered and recycled in a closed loop into packaging for food contact again (= high-class recycling of post-consumer material, no downcycling!). All participants of the value chain collaborate and closed the recycling loop for school milk rPET cups.

Silver Awards:

PAPACKS REFILL CAPS

PAPACKS® Refill-CAP filled with products such as cream and/or cosmetic content and inserted into high-quality glass jar. Refill-CAP simply exchanged so that the high-quality cream jar continues to be used. Refill-CAP is made of 100% compostable and recyclable virgin fibers, coating ensures appropriate barrier characteristics dictated by the industry standards.

Woolworths PaperSeal® Meat Tray

Woolworths Food Company

A new paper tray format utilising a unique technology that incorporates an intuitive design of an easily peelable top film and bottom film to facilitate better recyclability. The new design has also been lightweighted by 9.7 grams per tray and uses 75% less plastic versus the previous packaging format.

Packaging Innovation Award

Organized by Dow

2021 winners (announced February 2022):

Diamond Winner

Brookfarm’s curbside recyclable, high barrier stand-up pouch by O F Packaging

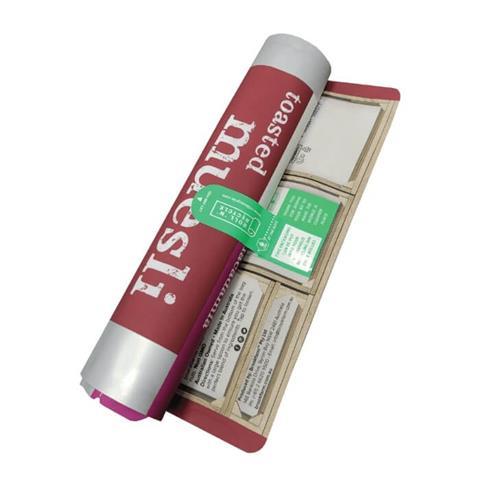

O F Packaging was given a challenge by their client Brookfarm to create a high barrier packaging structure to protect their muesli and granola that would also be easier to recycle and compatible with the mechanical recycling infrastructure in Australia.

The muesli and granola product is protected by flexible plastic packaging, which is notoriously tricky to recycle. Rather than wait for the industry to bring new products to market, O F Packaging chose to disrupt the market themselves and create a more sustainable flexible plastic package that is easier to recycle.

This ambition was not without its challenges. The new packaging needed to be just as effective as the existing packaging and maintain all its key attributes such as long shelf life and eye-catching shelf appeal. And making it easier to recycle meant ensuring the product could be recycled through existing kerbside pick-up. The old packaging would often end up being incorrectly classified as paper recycling in the sorting process and would contaminate the waste stream.

O F Packaging came up with a creative solution. Firstly, the new packaging is made from mono-polyethylene, making it compatible with existing recycling streams. Secondly, when the new container is empty, the pouch can be rolled into a cylinder by the consumer. The product label is used as a sticker to keep the packaging in that cylinder shape. It’s now 3D shape means the packaging can be dropped into the recycling bin for kerbside pick-up and remain in the correct plastic recycling stream.

Diamond Finalists

-

Pumpless handwash packaging by ITC Limited

-

Mavuno Bora hermetic bags by Packaging Industries Limited

-

Colgate Elixir by Colgate-Palmolive

-

McDonald’s Sundae cup and lid by Huhtamaki

-

Recyclable CanCollar® for canned beverages by WestRock

-

Hand sanitizer sachet by T.H.E.M

-

Kleenex® collective packaging by Kimberly-Clark de Mexico

-

Recyclable and plastic-free toothbrush packaging by GSK, by WestRock

-

Smarties recyclable paper packaging by Nestlé

Gold Award Winners

-

Low carbon green packaging technology mailing box by Boxtalk

-

SBP Dupla Ação swivel cap by Reckitt Benckiser

-

Recyclable polyethylene stand-up pouch by Microplast-Coldeplast

-

Three-dimensional molded pouch by Toyo Seikan Co., Ltd.

-

Veja Power Nature by Reckitt Benckiser

-

Laser engraved recycled water bottle by VALGROUP & DANONE

-

Circular economy pouch packaging for Zero Co. by O F Packaging

-

Universal electronics blister packaging for remote controls by STI Group

-

SAMBAZON açaí bowl packaging by Fuseneo, Inc.

-

AmLite heatflex recyclable retort pouch by Amcor

-

Recyclable paper functional barrier packaging for food by Mondi

-

Recyclable blister film for pharmaceuticals by Kp

-

Recyclable yerba maté SALUS packaging by Molinos Rio de la Plata

Silver Award Winners:

-

Compostable wax pods for cleaning concentrates by etee

-

Inflatable insulated protective packaging by YompBox

-

Plasma barrier for agrochemicals packaging by UNIPAC

-

Recyclable toothpaste tube by Colgate-Palmolive

-

Natrellis® dual ovenable fiber packaging by Sonoco Products Company

-

NetRoll® REC60 industrial stretch film by HIPAC SPA

-

Nescafé Protect Proslim™ recyclable alu-foil free instant coffee stick by Huhtamaki

-

flatBowl sugarcane food packaging by Foldesign.co

-

Garnier Men’s Shampoo Color sachet by L’Oreal

-

Recycled PP ‘Green Bags’ by Texplast Industries Limited

-

EcoLamHighPlus PE laminate with high barriers by Constantia

-

ProActive Recyclable® paper mailer with water resistance by ProAmpac

-

Recyclable polyethylene pouches by Constantia Flexibles India

Asia Star

Presidential Award

Papertube by Kolmar Korea

Kolmar Korea, a global cosmetics original design manufacturer introduced Papertube the cosmetic container that reduces the amount of plastic used in packaging by 80%. The paper body of the package can be torn using perforations to enable access to the last remnants of the product.

Full list of 2022 entries

No comments yet