Anti-counterfeit measures through product serialisation laws triggered the significant transformation of the healthcare industry, turning regulatory compliance into the top priority in 2018.

The international regulatory move to implement serialisation comes as a consequence of increasing drug falsification cases and supply chain loopholes. A comment piece by Veronika Shapka, Product Marketing at WIPOTEC-OCS.

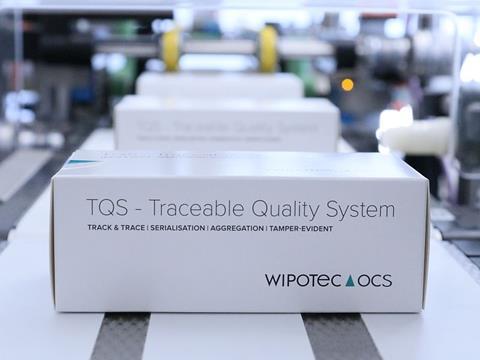

The World Health Organisation (WHO) estimates the share of substandard or falsified medical products in low- and middle-income countries to be as high as 10 percent . With EU FMD and the US DSCSA regulations coming into force by the turn of the year, pharma manufacturers around the globe accelerate their compliance efforts. Due to progressing globalisation of the healthcare markets, the European and US regulations affect companies even in countries that do not require serialisation on the national level. WIPOTEC-OCS registers high market demand for serialisation and aggregation solutions globally and reports implementation of more than 2000 Track and Trace projects in the pharmaceutical industry by the end of 2018.

From Serialisation to End-to-End Product Traceability

Some countries take anti-counterfeiting measures a step further requiring full-scale product traceability on the national level, enabled by product aggregation. As a pioneer in the area of pharmaceutical Track and Trace, Turkey has been monitoring the entire supply chain since 2010. Russia passed the law enforcing end-to-end drug traceability from 2020. The US will officially require aggregation of pharmaceuticals from 2023, but factually, most companies are aggregating their products already now. China is working to align their Track and Trace requirements with international standards. South Africa issued a draft law, which proposed serialisation and aggregation from 2022.

Flexible and Scalable Solutions

Global regulatory landscape demonstrates that the transition of the healthcare market will continue on the global scale. For production management, it means that packaging lines have to be flexible enough to support different serialisation and coding specifications of multiple markets. Regulatory compliance involves substantial investments into advanced systems and equipment and even replacing or modifying the existing packaging lines.

Serialisation as an Anti-Counterfeiting Measure in Other Industries

The problem of counterfeiting is unfortunately not limited to the healthcare industry only. Increasing globalisation of trade and inadequate control with low penalties for trading falsified products in many countries encourage the rise of global counterfeit activities. However, the counterfeit issue is not only a problem for the brand owners, whose products are being affected. In cosmetic, food and agrochemical industries it poses a risk to health and the environment, as the counterfeit products are not subject to safety regulations that original products are. Alone in the agrochemical sector, Europol estimates the share of counterfeit and unauthorised pesticides to comprise as much as 14% of the EU market. The organisation has sized 360 tons of illegal pesticides in 2018. According to the research conducted by the European Union Intellectual Property Office, EUR 1.3 billion is lost across the EU due to counterfeit agrochemicals.

These figures demonstrate that even a substantial initial investment in tamper-proof and anti-counterfeit technology will result in a high return on investment, regulatory compliance and competitive advantage in the longer run. Among all anti-counterfeiting solutions on the market, serialisation proves to be one of the most effective ones. The technology is giving manufacturers, wholesalers and distributors a systematic approach to detect counterfeiting and control product diversion. The pharmaceutical sector serves as a valuable example of how serialisation and Track and Trace technology can effectively ensure product integrity and supply chain transparency.