Paul Foot, partner and patent attorney in the Advanced Engineering group at European IP firm Withers & Rogers discusses Ocado’s proposed cellulose containers for its automated warehouse picking system.

Most consumers know of Ocado as the online-only supermarket that delivers groceries to your door for premium prices. But behind this consumer brand sits a behemoth of supply chain systems that is locked in a battle for supremacy in the emerging world of automated warehouse picking systems.

Its proprietary “Ocado Storage and Retrieval System” (OSRS) has been developed from its own supermarket business and is supplied to other retail and delivery businesses around the world, adding a significant revenue stream to the Ocado Group.

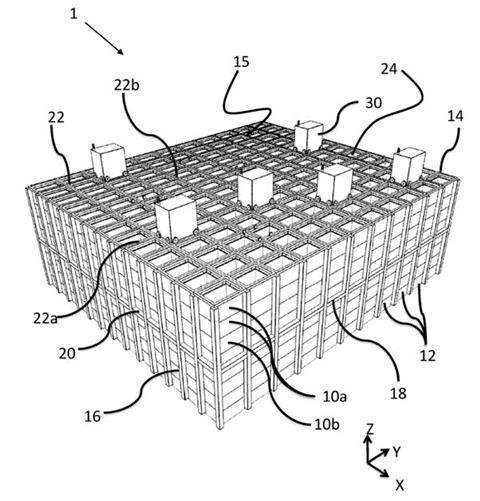

At the core of this system is a grid of containers stacked on top of each other and separated by tracks that run in both directions they call “The Hive”. The system includes a fleet of bots that can move in both directions along the tracks, as well as lower grabbers to pick up the containers and move them to locations where robotic arms or people can place the articles into bags for delivery to customers. The bots are centrally controlled by an AI system to pick and place the containers efficiently and safely.

As expected, Ocado has a sizeable portfolio of over 300 patent families with titles such as “Supply line management system for a robotic picking station” and “Method of synthesising training datasets for autonomous robotic control”.

Its latest patent is, however, more down-to-earth.

The containers or totes used in the system are typically made from plastic, which although cost effective, strong and lightweight, do pose problems if there is a fire. In particular, they are highly flammable, emit toxic fumes if they burn, and require the use of specialist powder-based fire extinguishing systems to put out the fire.

Ocado’s major competitor, Autostore, with whom they have had a major patent dispute, has previously proposed using metal containers rather than plastic, avoiding the flammable nature of plastic used in this system. Although these containers pose less of a fire-risk, they are considerably more expensive and heavy - not ideal for storage grids requiring thousands of such containers to be used.

Ocado’s invention, WO2025036879A1, proposes containers made of cellulose material – otherwise known as cardboard.

This may seem counter-intuitive, given that cardboard is also flammable, but the patent suggests that fires would cause less damage overall than for fires involving plastic containers. This is because they can be extinguished by sprinkler systems already present in typical logistics warehouses. Sprinklers can extinguish cardboard fires rapidly rather than needing to await fire fighters, fewer toxic fumes are emitted, which can reduce spoiling of stock that is not burned, and clear-up is likely to be a lot easier than for fires with plastics containers.

As well as improved fire safety, the cost of a cardboard container is significantly less, compared to its metal or plastic counterpart.

Despite the use of cardboard containers already being commonplace and so not patentable in isolation, this new patent is a great example of an innovative solution to a niche problem. In this situation, Ocado has tried to secure their monopoly to this niche solution by claiming the entire storage and retrieval system incorporating the grid, the bots and the stacks of containers in the hope that cardboard containers in combination with these other parts of the system are novel and inventive.

As shown below in figure 1, the storage containers (10) are stacked on top of one another, forming a grid framework structure (14) suitable for a warehousing or manufacturing environment. The framework is made up of a number of storage columns (24). Each container (10) holds a number of articles and are subdivided into different inventory items.

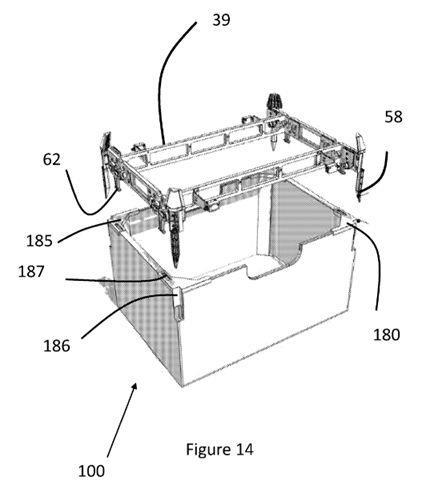

As shown in figure 14, a grabber device (39) is positioned above the container (100). Each locating pin (58) of the device is aligned with each corner of the container. When the grabber is lowered to engage with the container, the gripper elements (62) fit through corresponding apertures (187) in the rim portion (116) of the container. The gripper elements (62) then spread so that they hold the underside of the rim portion, and the container can be lifted.

Unfortunately for Ocado, it seems the use of cardboard containers in this sort of retrieval system is not new technology as the European Patent Office has uncovered an Autostore patent application published around a year before the Ocado one was filed that also mentions cardboard based containers. However, even if the general idea of cardboard containers is known, it may be that Ocado can obtain cover on the more specific design of container they propose.

This patent is a good example of finding the practical shortcomings of an existing system and developing new innovative solutions to these problems. In this instance, the new technology reduces the risk of severe fire damage within logistical warehouses, whilst also bringing down the cost for businesses.

No comments yet