TNA Solutions is set to showcase its case packing system and other primary and secondary packaging solutions at PACK EXPO International in Chicago, USA, November 3rd-6th, designed to meet growing demands for automation and efficiency in the food industry.

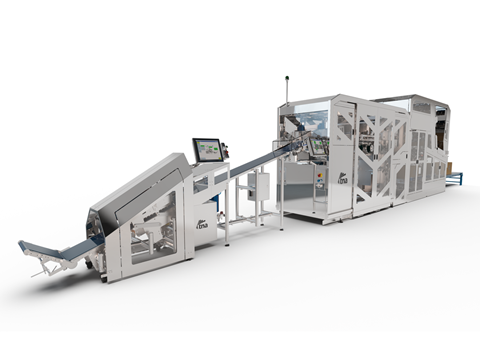

The exhibits will include tna ropac 5, which the company says is the ‘world’s fastest’ case packing system for flexible bags, capable of handling up to 200 bags per minute. The system features TNA’s patented semi-rotary bag stacking technology, catering to small-to-medium pillow-style bags for snacks, confectionery, pasta and cereal.

TNA says that according to a study by Deloitte and the Manufacturing Institute, 1.9 million manufacturing jobs are expected to remain unfilled in the US by 2033, underscoring the ‘urgent need’ for automation. It adds that as consumers become more health-conscious, there is a rising demand for smaller pack sizes that cater to their wellness goals.

However, TNA states increasing the speed of existing case packers often leads to reduced efficiency. The tna ropac 5 aims to address these challenges by offering tool-less changeovers and a compact design that integrates into existing production lines. The copmany states that Australian snack manufacturer Majans saw a 140% increase in throughput within 12 months after implementing the tna ropac 5.

TNA Solutions will also be exhibiting the tna robag 3e, a VFFS system, and tna auto-splice 3. Designed to work with the tna robag 3e, the tna auto-splice 3 is said to automatically splice packaging film without any downtime in an effort to eliminate manual intervention and ensure uninterrupted packaging.

The company states that for a typical 7-hour shift operation with 3 shifts per day, bagging at the speed of 140 bags per minute, the system can generate an additional 3.5 million bags over one year. This is said to reduce machine downtime by 385 hours per year, corresponding to an overall equipment efficiency gain of 5.1%.

TNA will also be showcasing the tna intelli-flav OMS 5.1, its on-machine seasoning system that provides powder flavouring and liquid oil in a single drum. The system is designed to ensure consistent and precise seasoning coverage, aiming to eliminate inconsistencies and reducing material waste while catering to a variety of products.

“U.S. food manufacturers have been significantly impacted by labour shortages, driving an increased demand for automation,” commented Mukul Shukla, vice president of TNA North America. “As the world’s largest market for snacks and the second largest for confectionery, the US provides an ideal platform for us to highlight our complete processing and packaging line solutions.”

TNA Solutions will be at booth N-5120 at PACK EXPO International.

In similar news, BW Flexible Systems introduced its new flow-wrapping machine for baked goods, the Hayssen R300, to its portfolio at PACK EXPO East, which was held in March in Philadelphia, USA. The hand-fed flow wrapper aims to provide a user-friendly experience for operators, with features such as automated adjustments to maximize uptime.

Syntegon has announced it will be presenting its machine and software solutions at this year’s FACHPACK, taking place in Nuremberg, Germany from September 24th to 26th. The solutions include the VFFS SVX Agile which produces pouches made from mono-material, the Kliklok ACE carton erector which forms glueless carton trays for cookies, and a horizontal line that packs bars in paper.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet