Recycled board manufacturer ESKA (part of RDM Group) has signed an agreement with Paques Biomaterials to use waste material from process water to create a biodegradable biopolymer, for applications including packaging and medicine.

The companies state the opportunity arose due to many paper producers – particularly for corrugated cardboard packaging – using an increasing amount of starch to help maintain the strength of their products. This starch dissolves in the process water of manufacturing mills that use recycled cardboard as a raw material, including ESKA’s board production plant in the Netherlands – where the increased starch content has been affecting operations with its closed-loop water system.

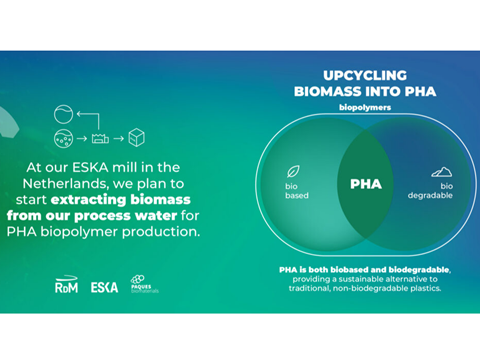

RDM Group says the biopolymer - called PHA - is biobased, biodegradable and compostable. In a new plant, the process water will be fermented and aerated in a series of biological reactors to form a specific type of biomass that will then be dried into a powder. The treated water will be returned to the mill. The drying process will use heat energy captured from the bioactivity itself, and any excess energy can be fed back to the mill.

Paques Biomaterials says it will then take the biomass powder away and turn it into an estimated 2,000 tonnes a year of PHA, or polyhydroxyalkanoate. The two companies add that PHA is similar in look, feel and performance to plastics produced from fossil fuels, and because it comes from a renewable, biobased resource, it offers ‘a sustainable alternative’ to traditional, non-biodegradable plastics.

Said to be suitable for food and beverage packaging, RDM Group says PHA has the potential to be used as a biodegradable barrier coating or adhesive in the company’s own recycled cartonboard products, aiming to increase the circularity of its operations.

Having successfully completed a pilot project to produce PHA, a dedicated joint venture will be created to complete the industrial business case feasibility study and apply for the necessary permits. If the concept proves to be successful and the permits are granted, then the plant will be operational by 2027.

Bert Bodewes, ESKA’s manager of Corporate Social Responsibility, said: “By building the world’s first industrial water purification system, which both purifies process water and produces PHA, our process water, which was previously worthless, becomes a valuable organic waste stream. If the PHA produced can then be used in our own products as a biodegradable barrier coating and/or adhesive then that will be circularity at its best.”

In May this year we heard from RDM Group’s chief sustainability and innovation officer, Krzysztof Krajewski, about its uncoated cartonboard solution, aiming to align with increased demand for recycled and recyclable packaging. The solution is said to be highly recyclable with the resilience needed for high-speed printing and folding.

In a July edition of the Spotlight, the company explained how its Barcelona mill is producing water-resistant recycled cartonboard that helps brands and retailers minimize the problem of sodden boxes. The board is made from premium fibres from selected paper sent for recycling, with a treatment on one side to control and reduce the amount of water absorption.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet