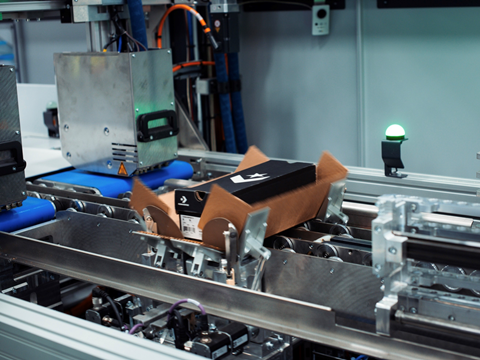

Ferag and Sparck Technologies have designed a continuous, ‘one-touch’ process to prepare boxes automatically, from order-picking to dispatch, in a ‘first’ for the e-commerce industry.

This development is set to facilitate a continuous packing process from picking the order to producing individual, fit-to-size boxes for shipping. The system’s Z-shaped conveyor section is designed to align and position every item for 3D scanning and processing at a ‘well-matched’ and ‘consistent’ pace sequenced with the upstream Ferag sorter.

Meanwhile, no manual intervention is required between upstream order-picking and the automated process of cutting, forming, sealing, and labelling the boxes. Not only is this hoped to provide ‘secure and compact’ boxed orders with ‘complete’ accuracy, but Ferag believes that risks such as labour shortages and illness among employees are reduced ‘significantly’.

Additionally, the solution is believed to lower costs, increase throughput, ramp up easily for peaks, and reassure retail clients.

The concept was inspired by Ferag’s Skyfall automated pouch sortation system. Served by ASRS and Autostore systems, Skyfall carries, directs, and sorts various picked goods from pick-stations to over 70 manual packing benches and one of Sparck Technologies’ CVP Everest automated ‘fit-to-size’ boxing systems.

While the overhead pouch sorter was originally intended to deliver single and multi-item orders to mostly manual packing desks, Ferag’s recently developed automated unloading capacity led the company to create a direct infeed to Sparck’s CVP Everest, automating the picking to auto-packing process.

“When it came to tendering and specifying the type of pouch needed, we put forward a couple of technologies for consideration, one being our soft pouch and the other being a hard pouch,” said Chris More, head of Sales at Ferag UK. “The hard pouch has a wire frame which allows it to be opened automatically by our newly developed auto-unloading technology. We had various options for unloading, and a gentle unloader was ultimately selected. This would prove critical.”

Reportedly, the CVP Everest can produce 1,100 boxes every hour with two operators. Yet concerns arose in the development process that presenting a range of product profiles to the boxing system in the right order and orientation was ‘a complex issue’.

As Ferag explains, manual induction of order items was previously a given in the otherwise automated processes of Sparck Technologies’ CVP machines – 3D scanning, cutting to size, folding, sealing, labelling, and despatching. The company was therefore investigating ways of auto-infeeding items into its automated boxing machines, whether as singles or multiple units.

“We immediately knew we could provide a solution as we were already working on a more holistic approach to the problem, with agnostic, scaleable and modular solutions,” commented Jo Bradley, business development manager for Sparck Technologies in the UK.

More continued: “We understood exactly what was needed, so we entered into close collaboration with Sparck to set out how the two systems would exchange information, creating a tight integration between upstream and downstream processes, with reliable hand-over and acknowledgement of product and order information.”

Ultimately, with Sparck working to introduce items of various sizes to the CVP Everest, the companies’ joint ‘one-touch’ solution launched after testing in late summer 2023. The final system is believed to maximize potential throughput and achieve the ‘accurate, consistent and reliable’ delivery of right-sized boxes to despatch.

“Automating the interface between order-picking and ‘fit-to-size’ boxing has been a ‘Holy Grail’ for the sector for a number of years,” Bradley explained. “Creating a smooth, seamless process free from human intervention has not been easy, given the complexity of the task, but now we have developed technology that aligns and positions individual items for induction into our CVP machines with great speed and accuracy. We are delighted to have worked with Ferag on achieving an industry first.”

In other news, EFI and Packsize have collaboratively developed the ‘world’s first’ on-demand box system that integrates full-colour printing on boxes using a single automated solution. It combines Packsize’s X5 fully automated Right-sized Packaging on Demand system with EFI’s Nozomi single-pass digital inkjet printer line for corrugated packaging – apparently reducing the manufacturing process from seven steps to one.

Meanwhile, EndFlex’s automatic vertical cartoning machine, Boxxer Kartnr-V, comes with an additional manual loading station. Customers can choose between manual or automatic loading only, or run both processes simultaneously – apparently unlocking precision, efficiency, and flexibility in the packing process.

Returnity has also modified its reusable shipping box, The Last Box, for compatibility with various distribution line setups in retail and e-commerce. It hopes to integrate ‘seamlessly’ into any logistics setup, claiming its suitability for ‘most existing’ scanning, labelling, and AI technologies.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet